Geïsoleerde visstaartplaten met cement zijn een belangrijk onderdeel voor spoorverbindingen en hebben isolatie eigenschappen. De isolatie van de lijm wordt voornamelijk gebruikt in de isolatie van naadloze lijnen met geïsoleerde spoorcircuits en naadloze lijnschakelaars, met uitstekende verbindingssterkte, isolatie en duurzaamheid, met goede waterdichte, stofdichte en schokdichte functies en kan zich aanpassen

I. Overzicht van Koppelschoenen

Spoorklemmen (spoorstootplaten), algemeen bekend als spoorbeugels, dienen om spoorstoten te verbinden. Ze worden ingedeeld in licht spoor, zwaar spoor en extra-zwaar spoor. Spoorklemmen fungeren als koppelbevestigingen tussen sporen en bieden een eenvoudigere en minder arbeidsintensieve installatie in vergelijking met lassen van spooruiteinden. Ze zijn ontworpen voor gebruik met spoorklembouten. De spoorklem heeft een centraal boutgat. Boven en onder de horizontale as van dit gat bevindt zich een bovenste werkvlak dat contact maakt met het onderste deel van de spoorstaafkop en een onderste werkvlak dat contact maakt met het bovenste deel van de spoorbaanbasis. Het achterste gedeelte van het bovenste werkvlak steekt omhoog om een overgangssegment te vormen dat verhoogd is ten opzichte van het spooroppervlak. Dit overgangssegment vormt een boogvormige brug langs de lengte van de spoorklem, met een hoger middenstuk en lagere uiteinden. Deze brugvormige spoorklemdesign vereenvoudigt de constructie en vermindert de wielaanslag op spoorstoten. Het verbetert de continuïteit van longitudinale vervorming op de verbinding en draagt bij aan een soepelere rit tijdens het passeren van treinen.

| Type |

Diameter ((mm) |

Gewicht ((kg) |

Materiaal |

| UIC54 |

108,5 mm * 27 mm * 41 mm |

23,92 kg |

40# |

| P50 |

820 mm * 104,2 mm * 46 mm |

18.7kg |

55# |

| P60 |

820 mm * 123,8 mm * 45 mm |

23,3 kg |

55# |

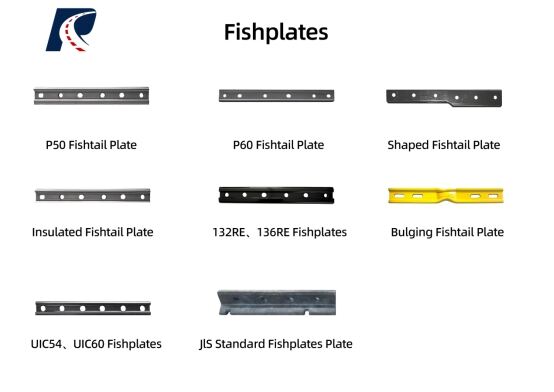

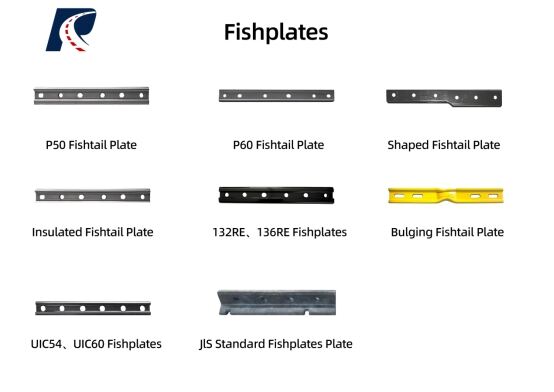

II. Soorten koppelschoenen

1. Lichte rails koppelschoenen, ook bekend als railschakels, en zware rails koppelschoenen, ook bekend als kranenrails schuine verbindingsschakels. Geïsoleerde koppelschoenen zijn volledig gemaakt van isolerende materialen. Geïsoleerde koppelschoenen zijn een nieuw type spoorbaanmateriaal dat is vervaardigd uit hoogwaardige composietmaterialen. Ze zijn bestand tegen corrosie, roest en UV-straling en zijn niet-geleidend en niet-magnetisch. Als thermohardende materialen kunnen ze niet opnieuw worden verwerkt, waardoor ze diefstalbestendig zijn.

2. Koppelschoenen worden ingedeeld op basis van railgewicht: 8 kg, 12 kg, 15 kg, 18 kg, 22 kg, 24 kg, 30 kg, 38 kg, 43 kg, 50 kg, 60 kg, 75 kg. Geïsoleerde lichte rails koppelschoenen omvatten 8 kg, 9 kg, 12 kg, 15 kg, 18 kg, 22 kg, 24 kg en 30 kg. Geïsoleerde lichte rails koppelschoenen zijn ook bekend als railschakels. Geïsoleerde zware rails koppelschoenen omvatten 38 kg en 43kg120, ook bekend als kranenrails schuine verbindingsschakels.

3. Standaard gietijzeren koppelschotten zijn er in twee types: vier-gats en zes-gats. Geïsoleerde koppelschotten internationaal omvatten BS47 en UIC-serie, bijvoorbeeld BS80A, BS75R, UIC60, UIC54. Deze worden verder onderverdeeld in vier specifieke types.

4. Koppelschotten worden geclassificeerd op basis van materiaal: nodulair gietijzer, Q235 gewalst staal, gesmeed staal, enz. Koppelschotten gebruiken voornamelijk staal met middelhoge koolstofgehalte en hoogkoolstofstaal als grondmateriaal. De belangrijkste koppelschotmodellen van ons bedrijf zijn 115RE, 132RE, UIC60, UIC54, BS80A, BS90A, BS100A en 90/91LB. Daarnaast produceren we bewerkte composietkoppelschotten, evenals gietijzeren of gietstaalkoppelschotten.

III. Specifieke afmetingen van veelgebruikte koppelschotmodellen

Opmerking: De bovenstaande afmetingen zijn alleen ter informatie. De werkelijke afmetingen kunnen variëren afhankelijk van de fabrikant, productiemethode en specifieke normen. Voor exacte afmetingen van specifieke koppelschotten dient u de betreffende normen of technische documentatie van de fabrikant te raadplegen.

IV. Eisen aan materiaalkwaliteit voor koppelschoenen

1. Materiaal van koppelschoen:

1) Koppelschoenen worden doorgaans vervaardigd uit hoogwaardig staal om te voldoen aan de eisen inzake sterkte en duurzaamheid tijdens gebruik.

2) Specifieke materialen kunnen gelegeerd staal, roestvrij staal, enzovoort zijn, waarbij de keuze afhankelijk is van de toepassingsomgeving en eisen.

2. Kwaliteitseisen:

1) Koppelschoenen moeten worden vervaardigd met geavanceerde processen zoals precisie koudbuigen, CNC-snijden en precisielassen om dimensionele nauwkeurigheid en platheid te garanderen.

2) De oppervlaktekwaliteit van koppelschoenen moet uitstekend zijn, zonder gebreken zoals scheuren, vouwen, bellen, insluitsels of walschaal.

3. Mechanische eigenschappen van klemplaten voor koppelingen:

Moet voldoen aan relevante normen, inclusief treksterkte, vloeisterkte, hardheid en andere gespecificeerde kengetallen.

V. Toepassing Toepassingsgebied van diverse modellen koppelschoenen

1. Conventionele Spoorwegen:

1) Koppelplaten met een gewichtsklasse van 43, 50, 60 en 75 kg/m worden veel gebruikt voor het verbinden en bevestigen van conventionele spoorbaansecties.

2) Deze koppelplaten zorgen voor stabiliteit en veiligheid van treinen tijdens bedrijf.

2. Hoge-snelheidslijnen:

1) Koppelplaten voor hogesnelheidslijnen moeten aan strengere eisen voldoen.

2) Zware koppelplaten zoals 60 en 75 kg/m worden bij voorkeur gebruikt vanwege hun hoge sterkte en duurzaamheid.

3. Stedelijk Spoornetvervoer:

1) Metro's, lichte spoornetwerken en vergelijkbare stedelijke spoorsystemen maken eveneens gebruik van deze koppelplaten voor de verbinding en bevestiging van de sporen.

2) Geschikte modellen en specificaties van koppelplaten worden geselecteerd op basis van specifieke bedrijfsomstandigheden en eisen.

4. Gespecialiseerde Spoorwegen:

1) Industriële spoorwegen, bosbouwspoorwegen en vergelijkbare gespecialiseerde lijnen kunnen unieke bedrijfsomstandigheden en eisen tegenkomen.

2) Gespecialiseerde koppelplaten worden geselecteerd op basis van specifieke omstandigheden om aan deze bijzondere eisen te voldoen.

Schakelaar Visplaat

De cruciale rol van veelgebruikte 43, 50, 60 en 75 kg/m koppelplaten in het spoorwegsysteem is onmiskenbaar. Hun afmetingen, materiaalkwaliteitseisen en toepassingsgebied worden bepaald op basis van specifieke gebruiksnormen om de veiligheid en stabiliteit van het spoorwegsysteem te waarborgen. In praktijktoepassingen moeten de betreffende normen en voorschriften strikt worden nageleefd bij het selecteren van geschikte koppelplaatmodellen en specificaties. Voor specifieke vragen ter plaatse en producteisen, kunt u contact met ons opnemen voor overleg.

| Nationaal Standaard Visschubplaat |

| T-Spoor |

Standaard |

Materiaal |

| 43 kg |

TB/T 2345-2008 |

B7 |

| 50kg |

| 60kg |

| BS Visschubplaat |

| T-Spoor |

Standaard |

Materiaal |

| BS75R |

BS 47-1 |

Europese

KLASSE 700

|

| BS80A |

| BS90A |

| BS100A |

| BS113A |

| JISE Standaard Spoorvisplaten |

| T-Spoor |

Standaard |

Materiaal |

| 37 A |

JIS E 1102-2001 |

SS490

S20C

|

| 50N |

| CR73 |

| CR¹00 |

| BS113A |

| Standaard spoorvisplaten volgens AREMA 2007 |

| T-Spoor |

Standaard |

Materiaal |

| 100lb.ASCE |

AREMA 2007 |

AREMA Kwaliteit/STAAL

KWALITEIT55#

|

| 115RE |

| 132RE |

| 136RE |

| Visplaten voor kraanspoor |

| T-Spoor |

Standaard |

Materiaal |

| 104Ib.CR |

AREMA 2007 |

AREMA Kwaliteit/STAAL

KWALITEIT55#

|

| 1051b.CR |

| 135Ib.CR |

| 1711b.CR |

| 175Ib.CR |

| Standaardlengte: 914,4 mm, geboorde of geponsde gaten, configuratie met 4 of 6 gaten |

| UIC Standaard Spoorstaafverbindingsplaten |

Toepasselijk spoor |

| Type |

Silly weight kg/m |

Formaat(mm) |

Materiaal |

Spoorwegmodel |

Spoorunit gewicht kg/m |

Implementatiestandaarden |

| een |

b |

c |

x |

| y |

| U79 |

23.92 |

108.53 |

27 |

41 |

2.75 |

Grade700 |

UIC54 |

54.43 |

UIC |

| 2.75 |

| U85 |

29.68 |

120.92 |

24 |

45 |

2.75 |

Grade700 |

UIC60 |

60.34 |

UIC |

| 2.75 |

| Visplaatstandaarden: UIC 864-4 Standaard, UIC 864-8 Standaard |