I. Përmbledhje e Produktit

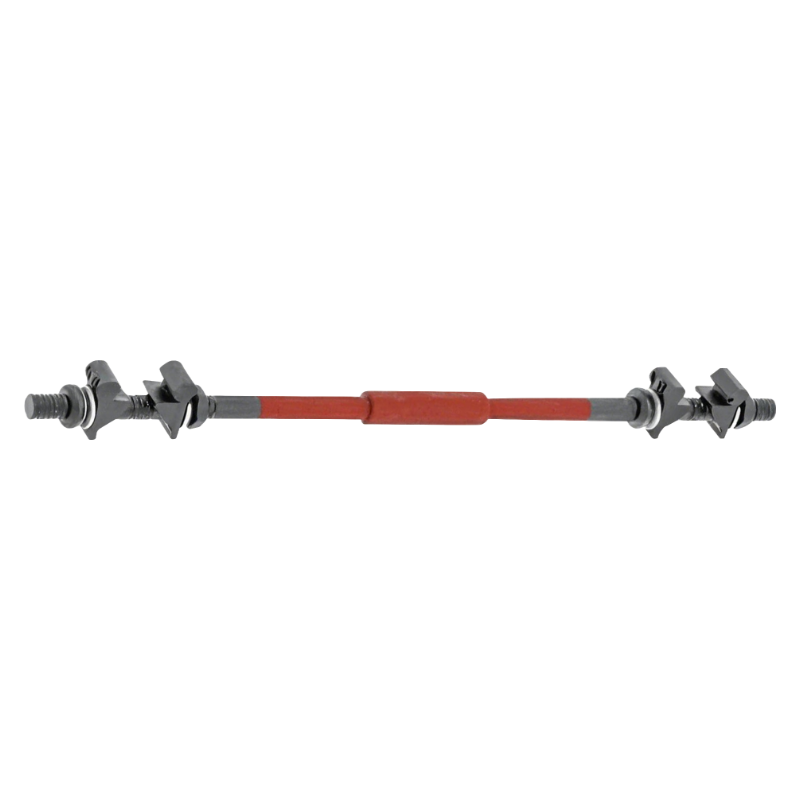

Rastëllja e Releve me Katër Dhëmbësh është një mjet profesional i mirëmbajtjes manual që është zhvilluar pavarësisht nga Yuerui International, i projektuar veçanërisht për pastrimin, klasifikimin dhe nivelimin e gurëve të agregateve në shtreallën e traseve hekurudhorë. Duke patur një konfigurim të optimizuar me katër dhëmbë, ky produkt është i përshtatur për mjedisin kompleks operativ të trasheve hekurudhorë, duke lejuar heqjen efikase të mbeturinave, bimësisë dhe lëndës së depozituar midis hapësirave të gurëve të agregateve, ndërkohë që siguron që nuk dëmton lidhëset e rrotullave, shiritë ose sipërfaqet e rruzave. Ai gjen zbatim të gjerë në skenare mirëmbajtjesh të hekurudhave me shpejtësi të lartë, hekurudhave konvencionale dhe sistemeve urbane të transportit me korridor hekurodhor, duke shërbyer si mjet portativ kyç për ekipazhet e operimit dhe mirëmbajtjes hekurudhore. Me strukturën e tij të fortë, dizajnin e lehtë dhe përdorimin ergonomik, ai përmirëson në mënyrë të konsiderueshme efikasitetin e punës së mirëmbajtjes së shtreallës, rrit aftësinë bartëse të ngarkesës dhe stabilitetin e strukturës së trasesh dhe ofron mbështetje të besueshme për funksionimin e sigurt dhe të qetë të sistemeve hekurudhore në mbarë botën.

II. Specifikimet Kyçe

| Kategoria e Specifikimeve |

Specifikime të Larg |

| Gjatësia e përgjithshme |

1300 mm (Modeli Standard) / 1600 mm (Model me Gjatësi të Rritur) |

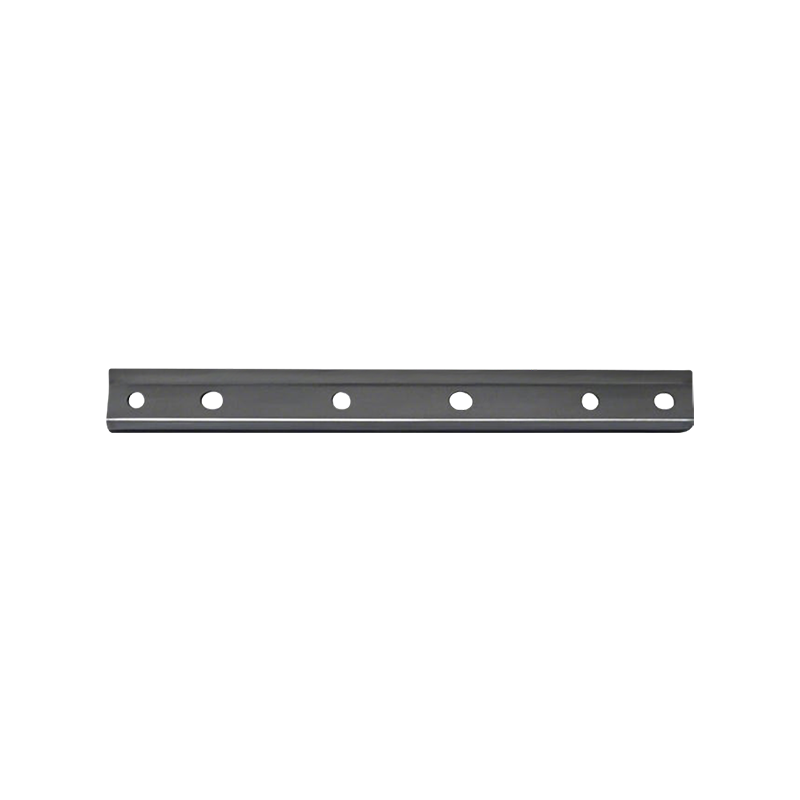

| Parametrat e Bërthamës së Kullot |

4 kullota; Lënda e kullotave: Çelik i fortë i karbonit me prishje (65Mn); Diametri i kullotës: 14 mm; Hapësira midis kullotave: 70 mm; Gjatësia efektive e kullotës: 280 mm |

| Përdorni materialet |

Plastikë e fortesuar me fibra të qelqit me rezistencë të lartë (FRP) / Aliazh lehtë aluminiumi (dy opsione) |

| Fortësia e Kullotave |

HRC50-54 (pas trajtimit termik të ftohjes dhe përpunimit të përsëritur) |

| Pesha e produktit |

1,4 kg (Modeli Standard) / 1,7 kg (Model me Gjatësi të Rritur) |

| Struktura e Lidhjes |

Kullota & dornja: Fiksime e dyfishtë me çelik të fortesuar + ngjitës epoksidik me rezistencë të lartë; Fundi i dornjës: Dorëz gome antizhvajtëse |

| Trajtimi sipërfaqësor |

Kullota: Përshkurtim me oksid të zi + imersion me lak antirrënie; Dornja: Spray kundër korrozionit (FRP) / Anodizim (aliash alumini) |

| Faqja e temperaturës së funksionimit |

-40℃~75℃ (Përshtatet me mjediset ekstreme të ftohtë, me temperaturë të lartë dhe lagështie) |

| Rrethi Aplikimi |

Pastrimi i gurëve nën binarët e hekurudhës, heqja e mbeturinave, nivela e gurëve dhe përpunimi i fundit pas katastrofave në binar |

III. Përparësitë Kryesore

(1) Optimizimi me Katër Dhëmbë & Pastrim Efikas

Pozicioni simetrik me katër dhëmbë është projektuar shkencorish për të balancuar sasisë e pastrimit dhe fleksibilitetin e punës. Hapësira prej 70 mm midis dhëmbëve lejon nxjerrjen e shpejtë të mbeturinave të vogla, barërive dhe lëndës së rrjedhshme, duke ruajtur gurët e rendomtë dhe shmangien e humbjes së panevojshme të tyre gjatë mirëmbajtjes. Çdo dhëmbë ka një formë kursive me një kënd të caktuar përkuljeje, që rrit forcën e grumbullimit dhe të shkrifitjes, duke e bërë më të lehtë heqjen e mbeturinave të ngurtësuara dhe barërive me rrënjë brenda truallit të binarit. Krahasuar me rreshtuesit me tre dhëmbë, struktura me katër dhëmbë rrit zonën e pastrimit me 30% në çdo operacion, duke përmirësuar konsiderueshmisht efikasitetin e mirëmbajtjes, veçanërisht i përshtatshëm për detyra të mëdha pastrimi të truallit të binarit.

(2) Dhëmbë me Fortësi të Lartë & Qëndrueshmëri Afatgjatë

Skuqët janë bërë prej eliku të lartë karbonik 65Mn me cilësi të lartë, i cili kalon një trajtim termik të saktë të ftohjes dhe temperimit, duke rezultuar në një dendësi dhe fortësi të shkëlqyeshme. Ata mund të përballojnë rrotullime dhe heqje të vazhdueshme me intensitet të lartë pa u përkulur, deformuar ose thyer. Përshkrimi i oksidit të zi i kombinuar me imersionin e lakut kundër korrozionit formon një pengesë dyfishe kundër korrozionit, që reziston efektivisht ndaj reshjeve, borës, pluhurit dhe lagështisë së mbështetëses së gjurmës. Struktura e fortuar e dyfishtë e fiksimit midis skuqëve dhe dërzës siguron një lidhje të fortë pa çngjitje edhe gjatë punës së rëndë afatgjatë, dhe jetëgjatësia është 50% më e gjatë sesa ajo e raqeve të zakonshme.

(3) Dizajn Ergonomik & Punësim i Lekureshem

Dorëzka adopton një dizajn të lakuar ergonomik me një diametër të moderuar (32 mm), i cili përshtatet konturit të dorës së njeriut, duke zvogëluar shtypjen mbi dorë dhe kockën gjatë mbajtjes së gjatë. Merrja gome anti-rrëshqitëse në fund të dorëzkës është projektuar me tekstura të thyera-të hequra, duke rritur forcën e marrjes dhe shmangien e rrëshqitjes edhe në mjedise të vajosura ose të lagura. Dizajni i lehtë (minimumi 1,4 kg) zvogëlon intensitetin e përgjithshëm të punës së operatorëve, duke e bërë të lehtë për t'u transportuar në çanta mirëmbajtje. Modeli me dorëzë të gjatë i lejon operatorëve të punojnë pa u përkulur për një kohë të gjatë, duke ulur më tej lodhjen fizike.

(4) Mbrojtje e Sigurt & Përshtatshmëri e Gjerë

Kryet e çdo stafiqe janë të politizuar me një skaj të butë të rrumbullakosur, i cili efikashtikisht i shmangërryeke mbulimin e fiksuesve të rërajave, sipërfaqeve të dormanteve dhe trupave të rërajave gjatë funksionimit, duke mbrojtur integritetin e pjesëve hekurudhore. Produkti është plotësisht i përputhshëm me mjediset e shtrullit të rrugës hekuriur për hekurudhat me shpejtësi të lartë (rëra 60kg/m), hekurudhat konvencionale (rëra 43kg/m, 50kg/m) dhe transportin urbane me rrota hekuri (metropolit, tramvaj), dhe mund të përshtjellë me dormante prej betoni, dormante prej druri dhe lloje të tjera të shtrullit. Mund të funksionojë normalisht në diapazonin e temperaturave ekstreme nga -40℃ deri në 75℃, dhe është i përshtatshëm për mjediset e ashpra jashtë shtëpisë si fushat malore, rajonet e ftohta dhe zonat bregdetare me shpirtar kripë.

IV. Skenarët e Aplikimit

Ky mjet profesional mirëmbajtjeje përdoret gjerësisht në skenarë globale operimi dhe mirëmbajtjeje hekurudhore, përfshirë:

- Mirëmbajtja e Përditshme e Shtratit të Rrëshqitjes: Pastrimi i rregullt i copave të prishta, barërave dhe tokës së lirë midis boshlliqeve të gurit për të siguruar qëndrueshmërinë e strukturës së shtratit;

- Mirëmbajtja Pas Katastrofave Natyrore: Heqja e lëndës së turbullt, hirit dhe gurëve të grumbulluar në shtratin e binave pas reshjeve të shiut, borës ose stuhive rërë për të rikthyer aftësinë bartëse të shtratit të binit;

- Mirëmbajtja Precize e Hekurudhës së Shpejtë: Përfundimi dhe nivela e agregatit në shtratin e binit të hekurudhës së shpejtë për të plotësuar kërkesat e larta të saktësisë për funksionimin e trenave të shpejtë;

- Mirëmbajtja e Tunelit të Transportit Rrugor Urbane: Pastroja e shtratit të binit në tunelët e metrouit dhe të hekurudhës së lehtë, duke u përshtatur me hapësirën e ngushtë dhe mjedisin e lagësht të operacioneve nën tokë;

- Ndërtimi dhe Riorganizimi i Hekurudhës: Ndihma në sortim, ngritje në nivel dhe pastrim fillestar të agregatit gjatë ndërtimit të ri të hekurudhave dhe projekteve të rimontimit të binave të vjetra.

V. Përkushtimi i Markës

Si lider global në mjete dhe përbërës për funksionimin dhe mirëmbajtjen e hekurudhave, Yuerui International ka qëndruar gjithmonë besnike filozofisë themelore të „funksionalitetit, qëndrueshmërisë dhe sigurisë“ dhe është përkushtuar në ofrimin e produkteve dhe shërbimeve me cilësi të lartë për industrinë globale të hekurudhave. Raka e Katër Shpatave për Helezi prodhohet në përputhje të plotë me standardet ndërkombëtare për mjete hekurudhore, dhe çdo njësi kalon teste rigoroze të fortësisë, testime për rezistencë ndaj konsumit, testime për qëndrueshmëri të lidhjes dhe testime kundër korrozionit para se të dalë nga fabrika, duke garantuar që performanca e saj i plotëson plotësisht nevojat reale operative. Ne ofrojmë shërbime të plota para shitjes si konsultim për zgjedhjen e produkteve dhe studime terreni për nevojat aktuale, si dhe shërbime pas shitjes që përfshijnë garanci cilësie, udhëzime teknike dhe mbështetje mirëmbajtjeje. Yuerui International është e gatshme të punojë së bashku me ekipet globale të funksionimit dhe mirëmbajtjes së hekurudhave për të përmirësuar efikasitetin dhe cilësinë e punës së mirëmbajtjes së trasheve dhe për të ruajtur së bashku funksionimin e sigurt dhe të qëndrueshëm të sistemeve globale të hekurudhave.