I. Përmbledhje e Produktit

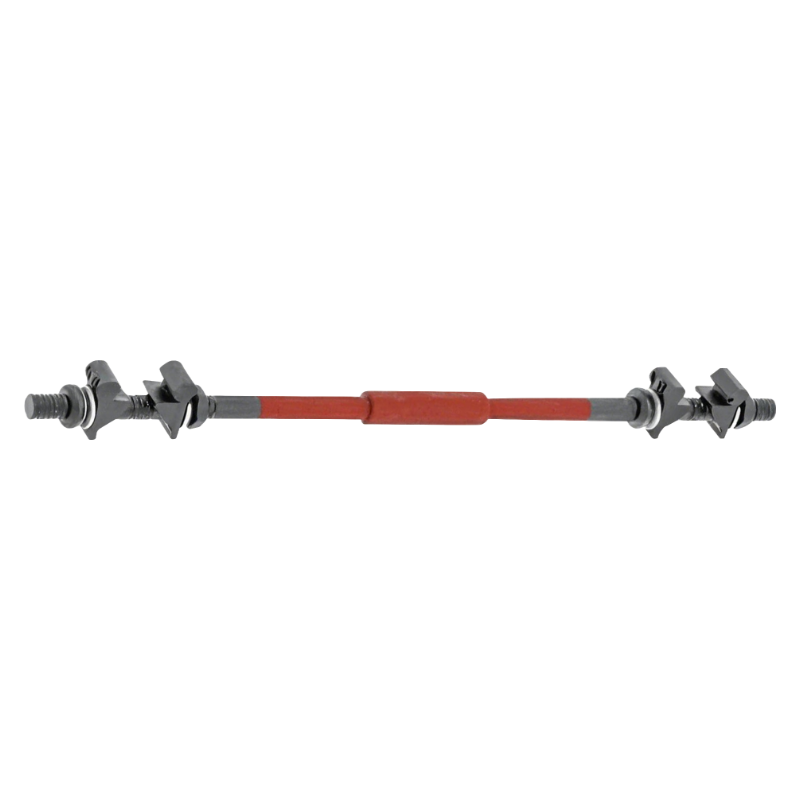

Klamperi për Ngjitjen e Rrethave të Helezit është një mjet profesional ngjitjeje të zhvilluar në mënyrë të pavarur nga Yuerui International, i dizajnuar veçanërisht për ngjitjen, transportin dhe instalimin e rretheve të helezit në projekte ndërtimi, mirëmbajtjeje dhe rimëkëmbjeje hekurudhore. Duke integruar teknologjinë e kapjes me vetëkyçje, dizajnin strukturor me bartje të lartë ngarkese dhe mbrojtjen kundër rrëshqitjes, ky produkt realizon kapjen e sigurt dhe të qëndrueshme të rrethave pa dëmtuar sipërfaqen e tyre. Ai gjen zbatim të gjerë në hekurudhat e shpejtësisë së lartë, hekurudhat konvencionale dhe projekte transiti urban me helez, duke u përputhur me lloje të ndryshme rrethash si 43kg/m, 50kg/m dhe 60kg/m. Si mjet kyç për operacionet e ngjitjes së rrethave, ai përmirëson efikasitetin e ndërtimit, zvogëlon intensitetin e punës manuale dhe garanton sigurinë e operacioneve të ngjitjes dhe integritetin e pjesëve të rrethit, ofruar mbështetje të besueshme për ndërtimin global të infrastrukturës hekurudhore.

II. Specifikimet Kyçe

| Kategoria e Specifikimeve |

Specifikime të Larg |

| Kapaciteti i Ngarkesës |

5t (Modeli Standard) / 8t (Modeli i Fortë) |

| Gjerësia e Rrugës së Aplikueshme |

60-150 mm (i përputhshëm me rrotat 43kg/m, 50kg/m, 60kg/m) |

| Material Kryesor |

Trupi ngjeshës: Çelik legher me forcë të lartë (42CrMo); Kaci i varjes: Çelik karboni forguar (Q345B) |

| Mënyra e Ngjeshjes |

Mekanizëm vetëkyçës mekanik (ngjeshje në varësi të ngarkesës, nuk kërkohen mjete shtesë kyçjeje) |

| Dimensionet e përgjithshme |

Gjatësia: 380 mm; Gjerësia: 160 mm; Lartësia: 220 mm (Modeli Standard); Gjatësia: 450 mm; Gjerësia: 180 mm; Lartësia: 260 mm (Modeli i Fortë) |

| Pesha |

12 kg (Modeli Standard) / 18 kg (Modeli i Fortë) |

| Trajtimi sipërfaqësor |

Përmbushje elektroforetike + sigilizim anti-mossi |

| Temperatura e Funksionimit |

-35℃~75℃ (përshtatje me temperaturë të gjerë) |

III. Përparësitë Kryesore

(1) Përshkrim i Vetë-Blokuar dhe i Sigurt dhe të Besueshëm

Duke adoptuar strukturën vetëlëkime të varur nga ngarkesa, forca e ngjeshjes rritet me rritjen e ngarkesës së ngritjes, duke realizuar vetëlëkimin automatik pa rrëshqitje. Dizajni unik i gojëzave të ngjeshjes përshtatet perfektisht me konturin e rrokut, dhe sipërfaqja e kontaktit është pajisur me dhëmbë antirrëshqitje të bërë prej aliazi rezistent ndaj konsumit, që jo vetëm përmirëson stabilitetin e ngjeshjes, por parandalon edhe gërvishtjen e sipërfaqes së rrokut. Produkti ka një faktor sigurie 3,5 herë më të madh se ngarkesa e renditur, i cili mund të parandalojë efektivisht aksidente si rënia e rrokut gjatë operacioneve të ngritjes, duke garantuar sigurinë e personelit dhe pajisjeve.

(2) Kapacitet i Lartë Ngarkese & Qëndrueshmëri

Trupi i kapjes është bërë prej çeliku aliazh 42CrMo me rezistencë të lartë, i cili formohet përmes forguarjeje integrale dhe punimi preciz, dhe kalon nxitim dhe trajtim termik. Fortësia e tij në terheqje arrin ≥1080MPa, dhe mund të bartë ngarkesa të rënda në mënyrë të qëndrueshme pa deformim apo thyerje. Karambolja e varjes është bërë prej çeliku karbonik të forguar Q345B, i cili ka rezistencë të shkëlqyeshme ndaj goditjeve dhe fyerjes. Pushtja elektroforetike dhe sigilimi me vaj anti-korroziv formojnë një mbrojtje dyfishe kundër korrozionit, e cila mund të rezistojë nxehjes nga reshjet, borra, pluhuri dhe mjediset e ashpra të tjera, dhe jetëgjatësia është më shumë se dy herë ajo e klipeve të zakonshme për ngjitje.

(3) Adaptueshmëri Fleksibël & Operim i Lehtë

Dizajni i përshtatshëm i gojëzës së kapjes lejon rregullimin e fleksibël sipas gjerësisë së shinash të ndryshme, duke realizuar përdorimin universal të modeleve të shumta të shinave, duke eliminuar nevojën për përgatitjen e disa grupe mjetesh ngjitjeje. Produkti adopton një dizajn të lloqit, i cili është i përshtatshëm për kapje dhe zhmontim të shpejtë të shinave, dhe një operator i vetëm mund të kryejë operacionin, duke përmirësuar në mënyrë të konsiderueshme efikasitetin e ndërtimit. Struktura kompakte dhe shpërndarja e arsyeshme e peshës e bëjnë të lehtë për bartje dhe përdorim në vendet e ngushta të ndërtimit si shtratin e trakionit dhe tunelët.

(4) Dizajn i Humanizuar & Mbrojtje Komplete

Këndi i kandilës së ngjeshjes është projektuar me një kënd të rrumbullakosur, i cili shmang skajet e mprehta që mund të dëmtojnë sipërfaqen e rrokut dhe siguron integritetin e tij. Karamollja e varjes është pajisur me një shkuf sigurie, e cila parandalon rrëshqitjen e litarit të varjes gjatë funksionimit. Sipërfaqja e dorëzës së punës është e mbuluar me gomë antiglishtë, e cila përmirëson ndjesinë e kapjes dhe zvogëlon lodhjen e operatorit gjatë përdorimit të gjatë. Produkti është pajisur me një tregues ngarkese, i cili tregon në kohë reale ngarkesën e ngritjes dhe shmang operimet me ngarkesë të tepërt.

Ky mjet ngritjeje përdoret gjerësisht në projekte globale të ndërtimit dhe mirëmbajtjes së hekurudhës, përfshirë:

- Ndërtimi i Ri i Hekurudhës: Ngritja dhe vendosja e rrokbave në fazën e vendosjes së trasesë për hekurudha me shpejtësi të lartë, hekurudha konvencionale dhe transportin urbane me rrok;

- Mirëmbajtja dhe Rinovimi i Hekurudhës: Zëvendësimi i rrokbave të vjetër, ngritja e rrokbave të dëmtuar dhe transporti i rrokbave të rinj në projekte rivendoseje trase

- Ruajtja dhe Transporti i Rëreve: Ngjitja dhe ngarkimi i rërave në oborrat e hekurudhës dhe magazinat, si dhe ngarkimi dhe shkarkimi i rërave gjatë transportit;

- Inxhinieria e Rërës së Tunelit: Ngjitja dhe instalimi i rërave në tunelet hekurudhorë dhe seksionet nën tokë të metrouit, duke u përshtatur me nevojat e ndërtimit të mjedisve të ngushta dhe të mbyllura.

V. Përkushtimi i Markës

Si lider global në mjete dhe pjesë për ndërtimin e hekurudhave, Yuerui International ka mbajtur gjithmonë konceptin e „prodhimit të saktë, siguria e para“ dhe është përkushtuar në ofrimin e produkteve me cilësi të lartë dhe të besueshme për industriinë globale të hekurudhave. Klampera për ngjitjen e rrotullave hekurudhore prodhohet në përputhje të plotë me standardet ndërkombëtare të pajisjeve për ngritje, dhe çdo njësi kalon teste rigorozë mbajtëse të ngarkesës, teste të lodhjes dhe teste kundër rrëshqitjes para se të dalë nga fabrika, duke garantuar që performanca e saj i përgjigjet nevojave reale të ndërtimit. Ne ofrojmë shërbime të plota para shitjes si konsultim për zgjedhjen e produkteve dhe studime në terren për nevojat aktuale, si dhe shërbime pas shitjes që përfshijnë trajnime teknike, udhëzime për instalim dhe mbështetje mirëmbajtjeje. Yuerui International është gati të punojë së bashku me klientët globalë për të promovuar zhvillimin efikas dhe të sigurt të ndërtimit të hekurudhave dhe për të dhënë kontribut në përmirësimin e infrastrukturës globale të hekurudhave.