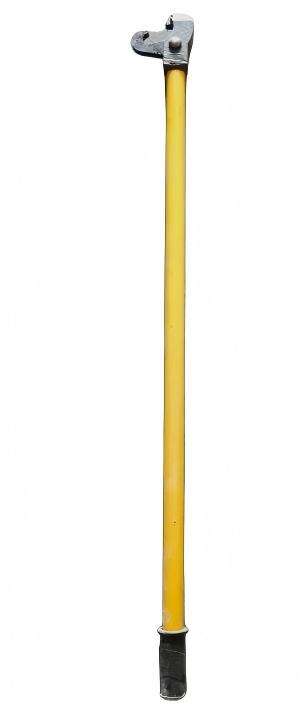

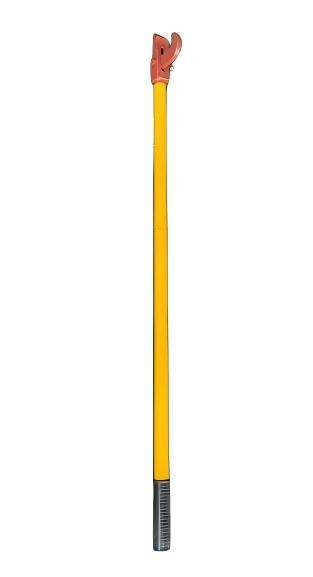

The Railway Clip Wrench is a specialized hand tool independently developed by Yuerui International for the installation, disassembly, and maintenance of railway elastic clips. Targeting the core operational needs of rail fastener systems in high-speed railways, conventional railways, and urban rail transit, it integrates precision engineering, wear-resistant materials, and labor-saving mechanics. As an indispensable tool for railway track maintenance, this product is tailored to match the structural characteristics of rail clips (such as Type IV/V elastic clips and bar-spring clips), enabling quick and damage-free operation on fasteners. It significantly reduces manual labor intensity, improves maintenance efficiency, and ensures the stability and safety of rail connections, providing reliable technical support for global railway operation and maintenance teams.

| Specification Category | Detailed Specifications |

| Overall Length | 380mm (Standard Model) / 520mm (Long-Reach Model) |

| Working Head Design | Customized jaw with anti-slip serrations (compatible with 12-25mm clip thickness) |

| Main Material | High-strength carbon steel (SCM440) with heat treatment |

| Surface Treatment | Black oxide coating + anti-corrosion oil immersion |

| Rated Tensile Force | ≥280N |

| Weight | 1.8kg (Standard Model) / 2.3kg (Long-Reach Model) |

| Handle Design | Ergonomic non-slip rubber grip (grooved texture) |

| Applicable Clip Types | Type IV/V elastic clips, bar-spring clips, conventional rail clip series |

| Operating Temperature | -25℃~75℃ (Wide temperature adaptation) |

(1) Precision-Matched Design

The working head is precision-machined based on the structural parameters of mainstream railway clips, with a curved jaw that fits closely with the clip contour. The anti-slip serrations enhance grip force, avoiding slipping or scratching the clip surface during operation. It supports multi-type rail clips, perfectly adapting to the fastener systems of high-speed railways (60kg/m and above rails), conventional railways (43kg/m, 50kg/m, 60kg/m rails), and urban rail transit, eliminating the need for frequent tool replacement.

(2) Superior Wear Resistance & Durability

Crafted from high-strength SCM440 carbon steel, the wrench undergoes integral heat treatment, with a hardness reaching HRC48-52, enabling it to withstand repeated torque impacts without deformation or breakage. The black oxide coating combined with anti-corrosion oil immersion forms a double protection layer, effectively resisting rust, oxidation, and corrosion from track-side moisture, dust, and chemical substances. The service life is extended by 40% compared to ordinary carbon steel wrenches, suitable for long-term outdoor and harsh environment operations.

(3) Labor-Saving & Ergonomic Operation

The lever structure is optimized through mechanical simulation, with a scientific force arm ratio that reduces operational torque by 30%, allowing operators to complete clip installation and disassembly with less effort. The handle is wrapped in high-density non-slip rubber, with a grooved texture that enhances hand friction and reduces fatigue during prolonged holding. The weight distribution is balanced, and the compact design enables flexible operation in narrow spaces such as track bed gaps, improving construction convenience and efficiency.

(4) Safe & Damage-Free Operation

The rounded edge design of the working head prevents scratches on rail clips and fastener components, protecting the integrity of railway parts and avoiding potential safety hazards caused by component damage. The product passes strict load-bearing tests and meets international railway tool safety standards, with stable performance and no sudden failure during operation. The non-slip grip ensures firm control even in oily or wet conditions, reducing operational risks for construction personnel.

This tool is widely used in global railway track maintenance and construction projects, including:

Yuerui International, as a global leader in railway components and tools, adheres to the concept of "quality-driven, innovation-led" and is committed to providing professional and reliable products for the global railway industry. The Railway Clip Wrench is manufactured in strict accordance with international quality standards, with a full-process quality control system covering raw material selection, production processing, and finished product testing. We offer comprehensive after-sales services, including technical consultation, product customization, and repair support, and provide relevant operation guidelines and training to help customers improve maintenance efficiency and reduce costs, jointly safeguarding the safe and seamless operation of global railway systems.

|

|

|

|

|