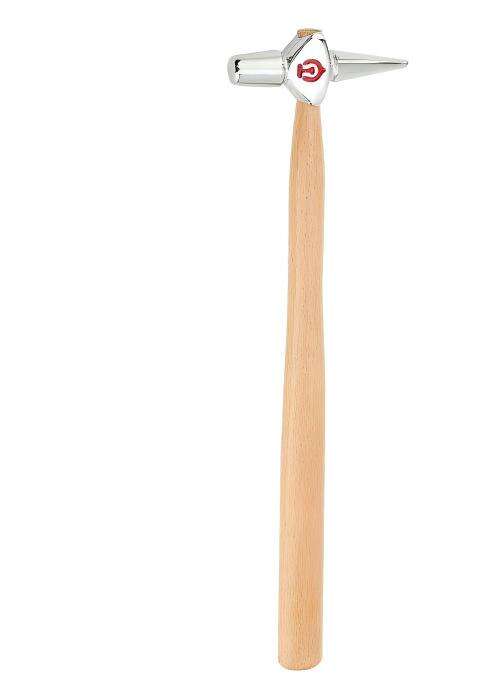

The Railway Inspection Hammer is a professional detection tool independently developed by Yuerui International, specifically designed for the daily inspection and fault diagnosis of railway components such as rails, fasteners, sleepers, and connecting parts. Integrating precise acoustic feedback design, wear-resistant material selection and ergonomic grip, this product helps inspectors quickly identify hidden faults such as looseness, cracks, and internal defects of components by judging the sound difference generated by knocking. It is widely applicable to high-speed railways, conventional railways, urban rail transit and other scenarios, and is an indispensable portable tool for railway operation and maintenance teams. With its lightweight design and reliable performance, it effectively improves the efficiency and accuracy of inspection work, providing a strong guarantee for the safe operation of railway systems.

| Specification Category | Detailed Specifications |

| Overall Length | 320mm (Standard Model) / 400mm (Long-Handle Model) |

| Hammer Head Dimensions | Diameter: 50mm (round head); Width: 35mm (flat head) |

| Main Material | Hammer head: High-carbon steel (45#) with heat treatment; Handle: Glass fiber reinforced plastic (FRP) / solid wood (optional) |

| Hardness | Hammer head: HRC52-56 |

| Weight | 280g (Standard Model) / 350g (Long-Handle Model) |

| Handle Design | Anti-slip frosted surface (FRP model); Polished smooth surface (solid wood model) |

| Additional Function | Built-in magnetic nail puller (hammer tail); Scale ruler (0-150mm) on handle |

| Operating Temperature | -30℃~65℃ (Wide temperature adaptation) |

| Surface Treatment | Hammer head: Chrome plating; Handle: Anti-corrosion spray (FRP model) |

(1) Precise Acoustic Feedback & Fault Identification

The hammer head is precision machined and heat-treated to ensure uniform material density, which can generate clear and distinguishable sounds when knocking different states of components. For intact components, it emits a crisp and full sound; for loose or cracked components, it produces a dull and hollow sound, helping inspectors quickly locate faults. The double-headed design (round head + flat head) is suitable for knocking different parts: the round head is used for rails and sleepers, and the flat head is for small fasteners and connecting bolts, improving the versatility of inspection.

(2) High Wear Resistance & Long Service Life

The hammer head is made of high-carbon 45# steel, which undergoes quenching and tempering heat treatment, with high hardness and excellent wear resistance. It can withstand long-term high-frequency knocking without deformation or chipping. The chrome-plated surface of the hammer head effectively resists rust and corrosion from outdoor moisture, dust and rail-side chemical substances. The FRP handle has high tensile strength and impact resistance, which is not easy to break or deform, and its service life is 3 times that of ordinary wooden handle hammers.

(3) Ergonomic Design & Portable Operation

The handle adopts an ergonomic curved design, which fits the contour of the human hand, reducing the pressure on the palm during long-term holding. The anti-slip frosted surface of the FRP handle enhances the grip force, avoiding slipping even in oily or wet environments. The lightweight design (minimum 280g) makes it easy to carry in the operation bag, and the long-handle model can reach remote inspection positions without additional tools, improving the flexibility of operation.

(4) Multi-Functional Integration & High Practicality

The hammer tail is equipped with a built-in magnetic nail puller, which can easily absorb and pull out small iron parts such as loose nails, eliminating the need for additional tools. The scale ruler on the handle can be used for simple measurement of component gaps and defect sizes, providing convenience for on-site inspection records. The product is small in size and easy to store, which is suitable for daily patrol inspection and emergency maintenance work of railway inspectors.

This inspection tool is widely used in global railway operation and maintenance scenarios, including:

As a global leader in railway operation and maintenance tools and components, Yuerui International has always adhered to the concept of "precision, reliability and practicality" and is committed to providing high-quality products for the global railway industry. The Railway Inspection Hammer is manufactured in strict accordance with international railway tool standards, and each unit undergoes rigorous hardness testing, wear resistance testing and acoustic feedback testing before leaving the factory to ensure that its performance meets the actual inspection needs. We provide comprehensive pre-sales consultation and after-sales services, including product selection guidance, quality assurance and maintenance support. Yuerui International is willing to work with global railway operation and maintenance teams to improve the efficiency and quality of inspection work and jointly safeguard the safe and stable operation of global railway systems.