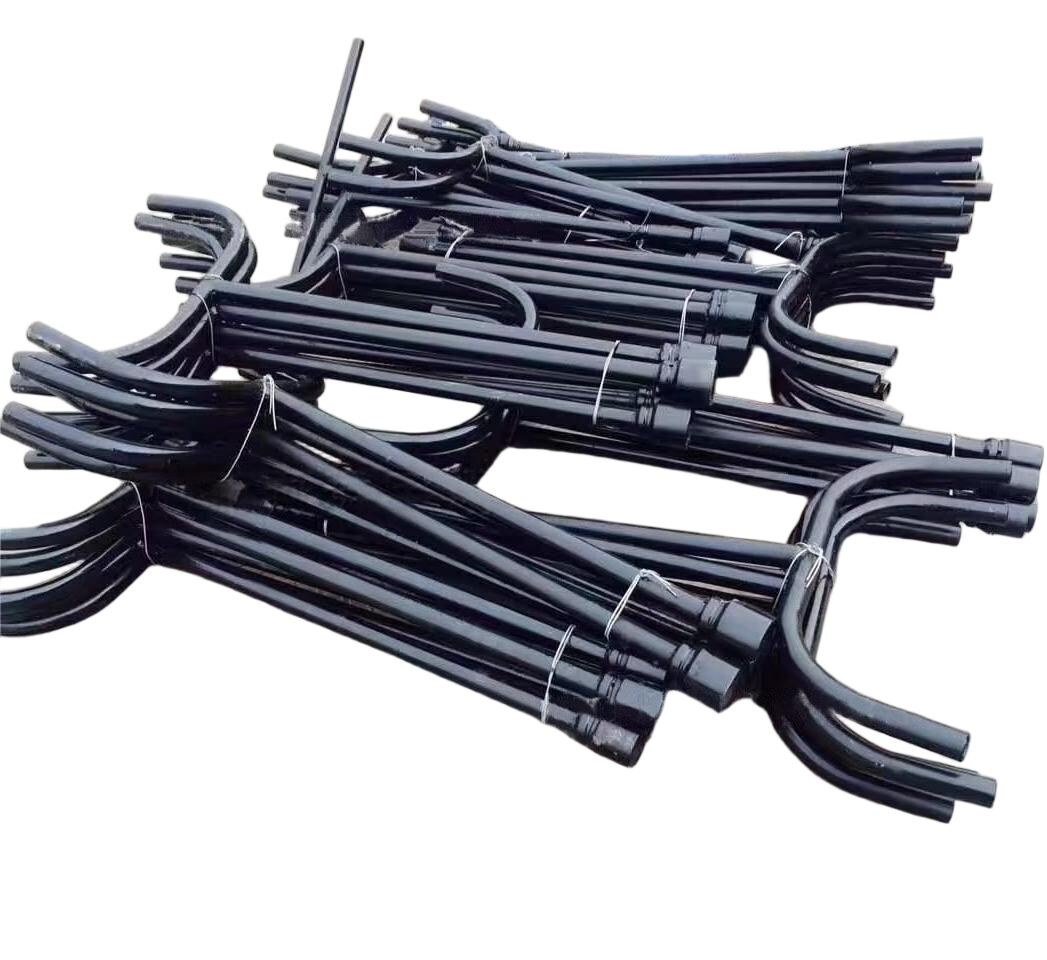

ประแจข้อต่อรูปตัวทีสำหรับงานทางรถไฟเป็นเครื่องมือประสิทธิภาพสูงที่พัฒนาขึ้นโดยเฉพาะโดย Yuerui International สำหรับสถานการณ์การดำเนินงานและบำรุงรักษาทางรถไฟ โดยเน้นความต้องการในการติดตั้ง การถอดประกอบ และการตรวจสอบประจำวันของอุปกรณ์ยึดรางเหล็ก ซึ่งผสานวัสดุความแข็งแรงสูงเข้ากับการออกแบบตามหลักสรีรศาสตร์ สามารถใช้งานได้กับระบบทางรถไฟหลายประเภท เช่น ทางรถไฟความเร็วสูง ทางรถไฟธรรมดา และรถไฟฟ้าใต้ดิน ในฐานะเครื่องมือช่วยหลักสำหรับงานดำเนินงานและบำรุงรักษาทางรถไฟ ผลิตภัณฑ์นี้มีข้อได้เปรียบสำคัญในด้านความสามารถในการปรับให้เหมาะสมอย่างแม่นยำ ความทนทาน และความสะดวกในการใช้งาน มอบวิธีการปฏิบัติงานที่ปลอดภัยและมีประสิทธิภาพให้กับทีมวิศวกรรมรถไฟทั่วโลก และช่วยสนับสนุนการดำเนินงานที่มั่นคงของระบบทางรถไฟ

| หมวดข้อกำหนด | ข้อมูลจำเพาะโดยละเอียด |

| ความยาวโดยรวม | 450 มม. (รุ่นมาตรฐาน) / 600 มม. (รุ่นยาวพิเศษ) |

| เส้นผ่านศูนย์กลางที่จับ | 32 มม. (ออกแบบด้ามจับกันลื่น) |

| ข้อกำหนดหัว | เข้ากันได้กับขนาดสลักเกลียวเฉพาะสำหรับทางรถไฟ (มีหลายรุ่น M16/M18/M20) |

| วัสดุหลัก | เหล็กอัลลอยโครเมียม-วาเนเดียมแบบตีขึ้นรูปทั้งชิ้น (Cr-V) |

| การบำบัดผิว | การดับความร้อนที่อุณหภูมิสูง + เคลือบป้องกันสนิมด้วยกระบวนการอิเล็กโทรโฟเรซิส |

| แรงบิดที่กำหนด | ≥350N·m |

| น้ำหนัก | 2.8กก. (รุ่นมาตรฐาน) / 3.5กก. (รุ่นขยาย) |

| อุณหภูมิในการทำงาน | -20℃~60℃ (ปรับตัวได้ในทุกสภาพแวดล้อม) |

(1) ความทนทานสูงพิเศษ

ใช้เทคโนโลยีการตีขึ้นรูปแบบบูรณาการจากเหล็กอัลลอยโครเมียมวานาเดียมคุณภาพสูง ไม่มีจุดเชื่อมหรือรอยตัด ทำให้ความแข็งแรงของตัวเครื่องเหนือกว่าเครื่องมือทั่วไปอย่างมาก สามารถทนต่อแรงกระแทกจากการใช้งานความถี่สูงและหนักหน่วงโดยไม่เกิดการบิดเบี้ยวหรือแตกหัก หลังผ่านกระบวนการชุบแข็งด้วยอุณหภูมิสูง ความแข็งจะอยู่ที่ HRC45-50 ซึ่งเพียงพอสำหรับการขันแน่นและการถอดสลักเกลียวทางรถไฟได้อย่างง่ายดาย อายุการใช้งานยาวนานกว่าเครื่องมือทั่วไปมากกว่า 3 เท่า ชั้นเคลือบป้องกันสนิมแบบอิเล็กโทรโฟเรซิสแยกความชื้น ฝุ่น และสารกัดกร่อนในสภาพแวดล้อมทางรางได้อย่างมีประสิทธิภาพ ทำให้มั่นใจได้ว่าเครื่องมือจะคงประสิทธิภาพที่เสถียรเป็นเวลานานภายใต้สภาวะการทำงานที่ซับซ้อน เช่น กลางแจ้งและภายในอุโมงค์

(2) การปรับตัวได้อย่างแม่นยำ

ออกแบบมาโดยเฉพาะสำหรับลักษณะของอุปกรณ์ยึดรางรถไฟ โดยขนาดหัวถูกกลึงขึ้นรูปอย่างแม่นยำเพื่อให้พอดีกับน็อตพิเศษของรถไฟความเร็วสูง รถไฟธรรมดา และรถไฟฟ้าใต้ดิน ช่วยป้องกันปัญหาการลื่นไถล รอยกัด หรือปัญหาอื่นๆ ระหว่างการใช้งาน ทำให้คงความสมบูรณ์ของอุปกรณ remarks การยึดได้ ครอบคลุมหลายรุ่นและข้อกำหนดที่สอดคล้องกับมาตรฐานน็อตยึดรางรถไฟหลักๆ สามารถปรับเข้ากับความต้องการในการดำเนินงานและการบำรุงรักษารางประเภทต่างๆ เช่น 43kg/m, 50kg/m และ 60kg/m เพื่อตอบสนองความต้องการในการใช้งานในหลากหลายสถานการณ์

(3) การออกแบบตามหลักอากาศพลศาสตร์

โครงสร้างด้ามจับรูปตัวทีให้จุดหมุนที่สามารถใช้แรงได้สองทิศทาง ช่วยลดแรงกายที่ต้องใช้ในระหว่างการปฏิบัติงาน ทำให้ผู้ปฏิบัติงานสามารถรักษาน้ำหนักตัวในท่าที่สบายได้แม้ในพื้นที่แคบหรือการทำงานระยะยาว ด้ามจับทำจากวัสดุยางกันลื่น และการออกแบบพื้นผิวช่วยเพิ่มแรงเสียดทานกับมือ ทำให้ยึดจับได้มั่นคงแม้ในสภาพแวดล้อมที่มีน้ำมันหรือความชื้นสูง ช่วยเพิ่มความปลอดภัยในการปฏิบัติงาน ความยาวของด้ามจับได้รับการปรับให้เหมาะสมทางกลศาสตร์ ซึ่งไม่เพียงแต่รับประกันคานงัดที่เพียงพอเพื่อยกระดับประสิทธิภาพการทำงาน แต่ยังคำนึงถึงความสะดวกในการพกพา เพื่อให้เคลื่อนย้ายได้อย่างคล่องตัวตามแนวราง

(4) ความปลอดภัยและความเชื่อถือได้

ผลิตภัณฑ์ผ่านการตรวจสอบคุณภาพอย่างเข้มงวด และเป็นไปตามมาตรฐานความปลอดภัยของอุตสาหกรรมรถไฟ มีแรงบิดที่ส่งออกอย่างมั่นคง ช่วยหลีกเลี่ยงความเสี่ยงในการดำเนินงานที่เกิดจากความล้มเหลวของเครื่องมือ โดยรวมโครงสร้างมีขนาดกะทัดรัด ไม่มีขอบหรือมุมแหลมคม ลดการบาดเจ็บจากการชนระหว่างการใช้งานได้; การกระจายน้ำหนักสมดุล ทำให้ไม่เกิดการเสียหลักขณะปฏิบัติงาน ช่วยเพิ่มความปลอดภัยให้กับบุคลากรก่อสร้างได้อีกขั้น

เครื่องมือนี้ถูกใช้อย่างแพร่หลายในโครงการซ่อมบำรุงและการดำเนินงานรถไฟทั่วโลก ซึ่งรวมถึง:

ในฐานะผู้นำระดับโลกในด้านชิ้นส่วนระบบรถไฟ Yuerui International มุ่งมั่นขับเคลื่อนความก้าวหน้าของอุตสาหกรรมผ่านคุณภาพและนวัตกรรม ผลิตภัณฑ์นี้ใช้เทคโนโลยีการผลิตขั้นสูงและวัตถุดิบคุณภาพสูง โดยดำเนินการภายใต้ระบบควบคุมคุณภาพอย่างเข้มงวดตลอดกระบวนการ เพื่อให้มั่นใจว่าผลิตภัณฑ์ทุกชิ้นจะเป็นไปตามมาตรฐานสูงด้านความน่าเชื่อถือและความทนทาน เราให้บริการหลังการขายและสนับสนุนทางเทคนิคอย่างครบวงจร เพื่อช่วยให้ลูกค้าสามารถดำเนินงานด้านการเดินรถและการบำรุงรักษาได้อย่างมีประสิทธิภาพ ร่วมกันรับประกันการดำเนินงานของระบบรถไฟระดับโลกให้มีความปลอดภัย มีประสิทธิภาพ และไร้รอยต่อ