The Science Behind Rubber Pad Vibration Control

Rubber pads serve as dynamic interfaces between machinery and their supporting structures, transforming harmful vibrations into manageable thermal energy. These elastomeric components work by creating a damping effect that absorbs oscillatory motions before they can transfer to surrounding equipment or building structures. The viscoelastic properties of quality rubber pads allow them to simultaneously provide equipment stability while isolating vibration frequencies that could cause premature wear. Industrial facilities worldwide rely on rubber pad installations to protect sensitive equipment from both internally generated vibrations and external environmental disturbances. The effectiveness of a rubber pad system depends on proper material selection, thickness calculation, and load distribution to match specific operational requirements. When correctly implemented, rubber pad solutions can reduce vibration transmission by up to 90% in some applications, dramatically extending equipment lifespan.

Vibration Isolation Mechanisms

Energy Absorption Through Material Properties

Rubber pads combat vibrations through their unique ability to convert mechanical energy into heat via internal friction. As vibrating equipment compresses and releases the rubber pad, the polymer chains within the material stretch and slide against each other. This molecular motion generates minute amounts of heat that effectively dissipates the vibration energy. High-damping rubber pad formulations excel at absorbing low-frequency vibrations common in heavy machinery like compressors and generators. The durometer (hardness) of the rubber pad determines its natural frequency characteristics, allowing engineers to select materials that target specific problematic vibration ranges. Some advanced rubber pad systems use layered constructions with varying densities to address multiple vibration frequencies simultaneously. The thickness of the rubber pad also plays a critical role, with thicker pads generally providing better isolation for lower frequency vibrations. This energy conversion process occurs continuously without any moving parts, making rubber pad systems exceptionally reliable for long-term vibration control.

Preventing Resonance Build-Up

Rubber pads break the chain of vibration transmission that could lead to dangerous resonance conditions in equipment and structures. By inserting a rubber pad between a vibrating machine and its foundation, the natural frequency of the system changes, preventing harmonic amplification. This is particularly important for rotating equipment like turbines and pumps that operate at constant speeds. Properly specified rubber pads ensure the system's resonant frequency stays well below or above the operating speed range. Some vibration isolation rubber pads incorporate air gaps or cavities that further disrupt vibration wave transmission. In multi-story industrial facilities, rubber pads prevent vibration harmonics from building as they travel through the structure. The damping ratio of the rubber pad material determines how quickly vibrations decay after the initial impulse. High-performance rubber pads for critical equipment often undergo extensive testing to verify their resonance control capabilities under simulated operating conditions.

Stability Enhancement Features

Load Distribution for Improved Balance

Rubber pads enhance equipment stability by evenly distributing dynamic loads across their entire surface area. The compressive properties of rubber pads allow them to accommodate minor irregularities in mounting surfaces that could otherwise cause instability. Heavy machinery benefits from rubber pad mounting systems that compensate for imperfect floor leveling while maintaining secure footing. The shear resistance of quality rubber pads prevents equipment from walking or creeping during operation despite vibration forces. Some stability-focused rubber pad designs feature textured surfaces or adhesive backing that increases friction with both equipment and foundation. In seismic applications, rubber pads allow for controlled movement during earthquakes while recentering equipment afterward. The simultaneous load distribution and vibration isolation provided by rubber pads create stable operating conditions that improve both safety and performance. Even in temporary installations, rubber pad shims can quickly stabilize equipment on uneven surfaces without permanent modifications.

Shock Absorption During Transient Events

Rubber pads provide critical protection against sudden shock loads that could damage equipment or disrupt operations. During startup and shutdown of heavy machinery, rubber pads absorb the initial torque reactions that could loosen mounting bolts. They cushion the impact of sudden stops in conveyor systems and material handling equipment. In construction equipment, rubber pads mitigate the shock from pile driving and compacting operations. The nonlinear compression characteristics of rubber pads mean they become progressively stiffer as loads increase, preventing bottoming out during severe shocks. Some shock-absorbing rubber pads use cellular or foam structures that compress predictably under impact loads. By extending the deceleration time during shock events, rubber pads significantly reduce peak impact forces transmitted to equipment and structures. This protection is especially valuable for precision machinery where sudden shocks could affect calibration or cause internal component damage.

Application-Specific Solutions

Industrial Machinery Vibration Control

Rotating equipment like pumps, compressors, and fans achieve dramatic vibration reduction when properly isolated with rubber pads. The rubber pad selection for these applications considers both the machine weight and its operating speed to ensure optimal isolation. Large chillers and HVAC systems use rubber pad mounts that prevent vibration transmission through building structures. Manufacturing equipment such as stamping presses and CNC machines benefit from rubber pads that isolate their high-impact operations. Even in power generation plants, massive turbines sit on custom-engineered rubber pad isolation systems that handle both static and dynamic loads. The rubber pads in these industrial applications often incorporate steel load plates that prevent excessive compression while maintaining vibration isolation properties. Regular inspection of industrial rubber pad mounts ensures they haven't hardened or cracked over time, which could compromise their vibration control performance.

Precision Equipment Stabilization

Laboratory instruments, medical imaging devices, and semiconductor manufacturing equipment require exceptional stability that rubber pads can provide. Optical tables use specialized rubber pad isolation systems that eliminate environmental vibrations affecting sensitive measurements. Electron microscopes achieve their high-resolution imaging thanks in part to vibration-damping rubber pad platforms. Cleanroom manufacturing equipment relies on rubber pads that isolate vibration without generating particulate contamination. The rubber pads used in these precision applications often have extremely consistent density and damping characteristics to ensure predictable performance. Some incorporate active vibration cancellation systems that work in concert with the passive damping of the rubber pad. Even in less extreme applications like office copiers and server racks, small rubber pads significantly reduce vibration transmission to surrounding surfaces. The common thread across all precision applications is the rubber pad's ability to provide both stability and isolation simultaneously.

Material Innovations

Advanced Compound Formulations

Modern rubber pad materials offer tailored vibration control properties through sophisticated polymer engineering. High-damping elastomers provide superior vibration absorption for low-frequency industrial equipment. Silicone-based rubber pads maintain their properties across extreme temperature ranges that would degrade conventional materials. Oil-resistant formulations prevent swelling in machinery applications where lubricant exposure is inevitable. Conductive rubber pads provide vibration isolation while preventing electrostatic buildup in sensitive electronics environments. Some advanced rubber pad compounds incorporate nanotechnology additives that enhance damping characteristics without compromising load-bearing capacity. These material innovations allow rubber pads to meet increasingly demanding vibration control requirements in industries like aerospace, energy, and transportation. The development of environmentally resistant rubber pad materials has expanded their use in outdoor and harsh environment applications where UV, ozone, and weather resistance are critical.

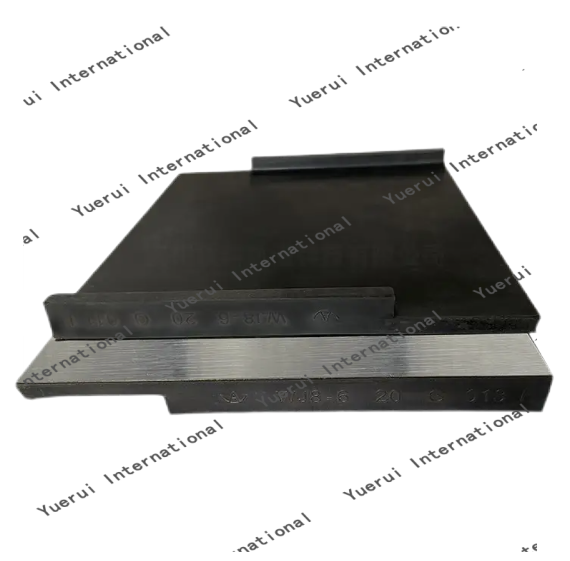

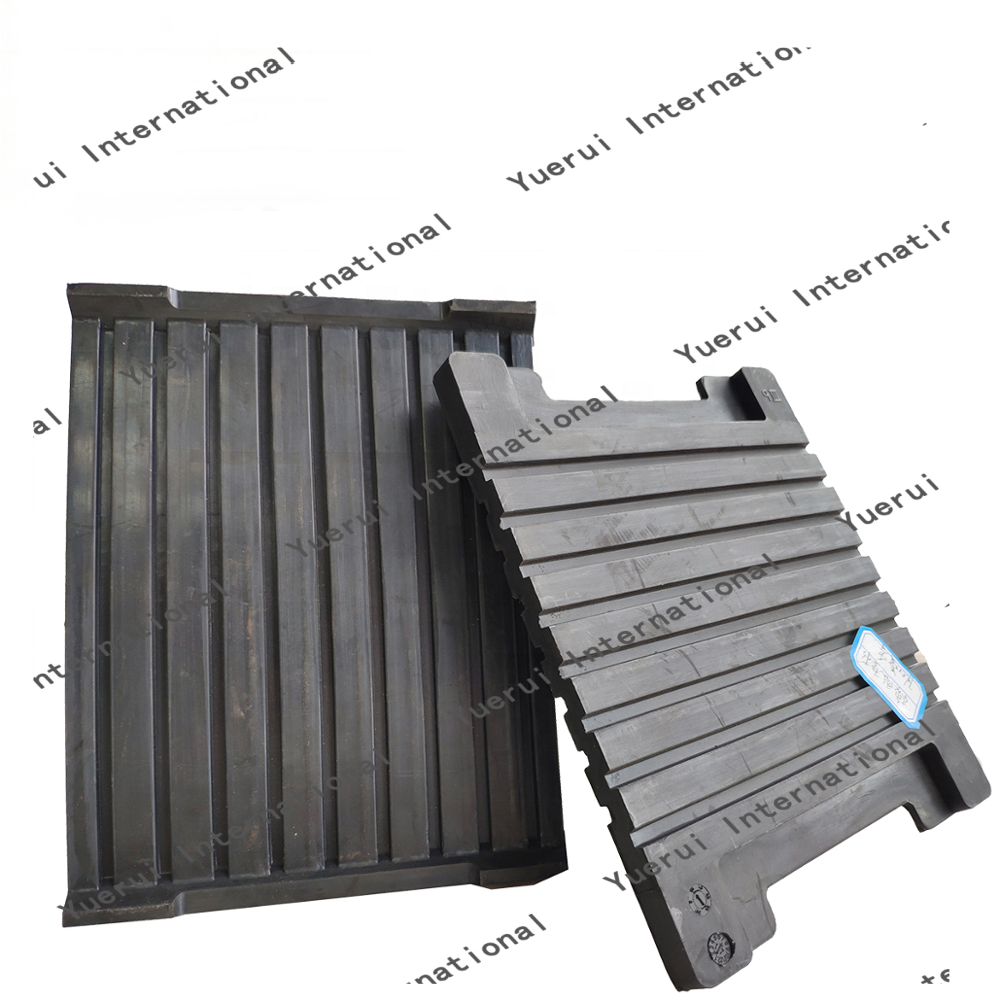

Custom Geometric Designs

Rubber pad manufacturers now offer engineered shapes that optimize vibration control for specific applications. Conical rubber pad mounts provide progressive stiffness that effectively isolates varying vibration frequencies. Ribbed or patterned rubber pad surfaces increase damping surface area without adding weight. Sandwich constructions combine rubber pads with metal plates to control both vertical and horizontal vibrations. Some specialized rubber pads feature hollow cores that enhance low-frequency isolation while maintaining stability. Custom-molded rubber pads can match irregular equipment bases perfectly, ensuring full surface contact for optimal vibration control. Even simple rubber pad designs benefit from precision manufacturing that ensures consistent thickness and density throughout the material. These geometric innovations allow rubber pads to solve vibration problems that would require complex mechanical systems otherwise. The ability to customize rubber pad shapes and compositions makes them adaptable to virtually any vibration control challenge.

FAQ

How often should rubber pad isolators be replaced?

Rubber pads in industrial vibration control applications typically last 5-10 years depending on environmental conditions and load factors. Signs that rubber pads need replacement include visible cracking, hardening, permanent compression set exceeding 15%, or diminished vibration isolation performance. Critical applications should include rubber pad inspections during routine maintenance shutdowns.

Can rubber pads completely eliminate equipment vibrations?

While rubber pads significantly reduce vibration transmission, no isolation system can eliminate vibrations entirely. Quality rubber pad installations typically achieve 70-90% vibration reduction, which is sufficient for most applications. Complete vibration elimination would require impractical rubber pad thicknesses that could compromise equipment stability. The goal is reducing vibrations to acceptable levels rather than absolute elimination.

Do rubber pads work for both horizontal and vertical vibrations?

Properly designed rubber pad systems can control vibrations in all directions, though vertical isolation is typically most effective. Some rubber pad mounts incorporate shear elements specifically for horizontal vibration control. Multi-axis vibration problems may require specialized rubber pad configurations with different stiffness characteristics in each direction.

How do temperature changes affect rubber pad vibration control?

Temperature variations can alter rubber pad stiffness and damping characteristics, potentially affecting vibration isolation performance. Cold temperatures make rubber pads stiffer, raising their natural frequency, while heat has the opposite effect. For extreme environments, select rubber pads specifically formulated to maintain stable performance across your expected temperature range.