Railway infrastructure forms the backbone of modern transportation systems, connecting cities, facilitating commerce, and enabling efficient movement of people and goods across vast distances. Within this complex network of steel rails, numerous components work together to ensure safe and reliable operation, with fishplates serving as one of the most critical yet often overlooked elements. These essential steel connectors play a vital role in maintaining track integrity, distributing loads, and preventing potentially catastrophic rail failures that could compromise passenger safety and operational efficiency.

Understanding the Fundamental Role of Fishplates in Railway Systems

Structural Integrity and Load Distribution

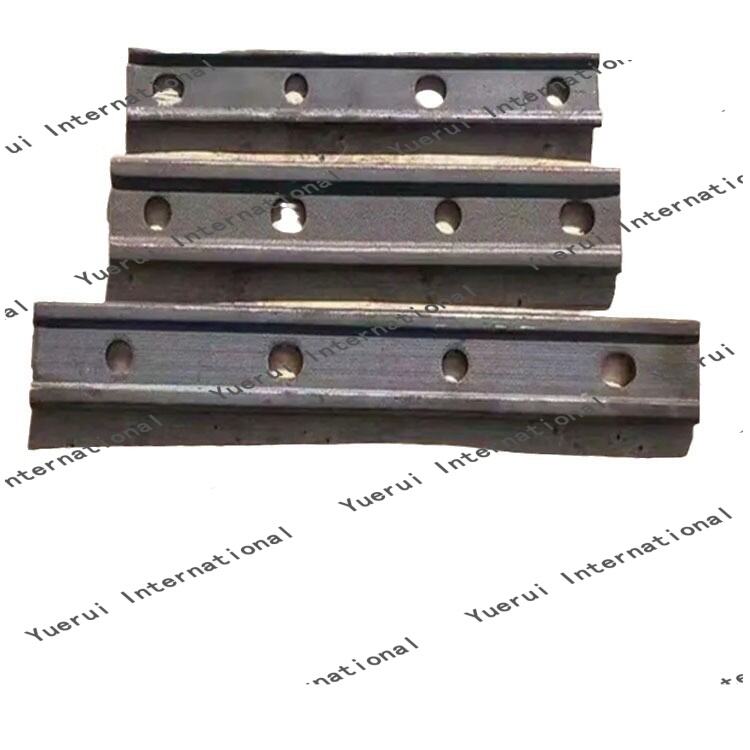

The primary function of fishplates extends far beyond simple rail connection, encompassing critical load distribution and structural reinforcement throughout the entire track system. These engineered components transfer mechanical stresses from moving trains across rail joints, preventing concentrated loading that could lead to metal fatigue, cracking, or complete rail failure. Modern fishplates are designed to withstand tremendous forces generated by heavy freight trains, high-speed passenger services, and varying environmental conditions while maintaining consistent track geometry.

Advanced metallurgical engineering ensures that fishplates possess the necessary tensile strength, impact resistance, and durability to perform reliably under extreme operational conditions. The precise manufacturing tolerances and material specifications directly influence how effectively these components distribute dynamic loads, reduce vibrations, and maintain proper rail alignment throughout their operational lifespan. Railway engineers carefully select fishplate configurations based on specific track requirements, traffic patterns, and environmental factors to optimize overall system performance.

Joint Stability and Track Continuity

Maintaining seamless track continuity represents another crucial aspect of fishplate functionality, directly impacting both safety and operational efficiency across railway networks. These components create secure connections between individual rail sections, preventing lateral movement, vertical displacement, and longitudinal creep that could compromise track stability. Properly installed fishplates ensure that trains experience smooth transitions between rail segments, reducing wear on wheels, minimizing noise levels, and enhancing passenger comfort.

The geometric precision of fishplate connections directly influences track quality indices, speed restrictions, and maintenance requirements throughout the railway system. High-quality fishplates maintain consistent rail head alignment, prevent joint depression, and minimize the formation of corrugations or other surface irregularities that could affect vehicle dynamics. Railway maintenance teams regularly inspect these connections to ensure optimal performance and identify potential issues before they develop into serious safety hazards.

Safety Enhancements Through Advanced Fishplate Technology

Prevention of Catastrophic Rail Failures

Modern fishplate designs incorporate sophisticated engineering principles to prevent catastrophic rail failures that could result in derailments, service disruptions, or potentially fatal accidents. These components serve as critical safety barriers, maintaining rail continuity even when individual rail sections experience stress concentrations, thermal expansion, or material defects. Advanced fishplates feature enhanced bolt configurations, improved bearing surfaces, and specialized metallurgy to withstand extreme loading conditions and environmental stresses.

Railway safety protocols emphasize the importance of regular fishplate inspection, proper installation procedures, and timely replacement of worn components to maintain optimal safety margins. Failure analysis studies consistently demonstrate that properly maintained fishplates significantly reduce the likelihood of joint-related accidents, track buckling incidents, and rail breaks that could endanger both passengers and railway personnel. Investment in high-quality fishplates represents a cost-effective approach to enhancing overall railway safety while minimizing long-term maintenance expenses.

Enhanced Monitoring and Predictive Maintenance

Contemporary railway management systems increasingly rely on advanced monitoring technologies to track fishplate performance, detect early signs of deterioration, and schedule preventive maintenance interventions. Smart sensing systems can monitor bolt tension, joint movement, and temperature variations at fishplate connections, providing real-time data to maintenance teams and enabling proactive replacement strategies. These technological advances help prevent unexpected failures and optimize maintenance scheduling to minimize service disruptions.

Predictive maintenance programs utilizing artificial intelligence and machine learning algorithms analyze vast datasets from fishplate monitoring systems to identify patterns, predict failure modes, and optimize replacement intervals. This data-driven approach enables railway operators to maintain higher safety standards while reducing maintenance costs and improving operational efficiency. Regular condition assessments of fishplates contribute to comprehensive track asset management strategies that prioritize safety while maximizing infrastructure longevity.

Reliability Improvements in Modern Railway Operations

Extended Service Life and Reduced Maintenance

Advanced materials science and manufacturing techniques have significantly improved fishplate durability, extending service life and reducing maintenance requirements across railway networks. Modern fishplates utilize high-strength steel alloys, specialized heat treatments, and precision machining to deliver superior performance characteristics compared to traditional designs. These improvements translate directly into reduced maintenance frequencies, lower lifecycle costs, and enhanced operational reliability for railway operators.

Corrosion-resistant coatings and surface treatments further enhance fishplate longevity, particularly in challenging environmental conditions involving moisture, salt exposure, or chemical contaminants. Enhanced durability reduces the frequency of track maintenance windows, minimizes service interruptions, and allows railway operators to maintain more consistent service schedules. The economic benefits of improved fishplate reliability extend throughout the entire transportation network, supporting efficient freight movement and reliable passenger services.

Operational Efficiency and Performance Optimization

Reliable fishplate performance directly contributes to operational efficiency by maintaining consistent track quality, reducing speed restrictions, and minimizing unscheduled maintenance interventions. High-performance fishplates enable trains to operate at design speeds safely, improving schedule adherence and maximizing network capacity utilization. The smooth load transfer characteristics of quality fishplates reduce dynamic forces transmitted to track structures, extending the service life of ballast, sleepers, and foundation elements.

Network reliability benefits from standardized fishplate specifications that simplify maintenance procedures, reduce inventory requirements, and enable more efficient resource allocation across extensive railway systems. Consistent performance characteristics allow maintenance teams to develop standardized inspection protocols, streamline replacement procedures, and optimize spare parts management. These operational improvements contribute to overall system efficiency while maintaining the highest safety standards throughout the railway network.

Environmental Considerations and Sustainability

Material Efficiency and Recycling

Sustainable railway operations increasingly emphasize the environmental benefits of durable, long-lasting fishplates that reduce material consumption and minimize waste generation. Modern fishplates are designed for extended service life, reducing the frequency of replacements and associated environmental impacts from manufacturing, transportation, and disposal activities. Advanced metallurgy enables the production of lighter yet stronger components that require fewer raw materials while delivering superior performance characteristics.

End-of-life recycling programs ensure that worn fishplates contribute to circular economy principles by providing high-quality steel feedstock for new railway components or other industrial applications. The recyclability of steel fishplates supports sustainable infrastructure development while reducing the environmental footprint of railway maintenance operations. Railway operators increasingly consider lifecycle environmental impacts when selecting fishplate suppliers and specifications, driving continued innovation in sustainable manufacturing practices.

Climate Resilience and Adaptation

Climate change presents new challenges for railway infrastructure, with extreme weather events, temperature fluctuations, and changing precipitation patterns affecting track stability and component performance. Advanced fishplates incorporate design features that enhance resilience to thermal stress, flooding, and other climate-related impacts while maintaining reliable performance throughout their operational lifespan. Temperature-resistant materials and expansion accommodation features help fishplates maintain structural integrity during extreme weather conditions.

Adaptive maintenance strategies recognize the importance of climate-resilient fishplates in ensuring continued railway operations despite changing environmental conditions. Proactive replacement programs, enhanced monitoring systems, and improved material specifications help railway networks maintain reliability while adapting to evolving climate challenges. Investment in resilient fishplate technology represents a critical component of climate adaptation strategies for transportation infrastructure.

Technical Specifications and Selection Criteria

Engineering Standards and Compliance

International railway standards establish comprehensive requirements for fishplate design, manufacturing, testing, and installation to ensure consistent safety and performance across global railway networks. These standards specify dimensional tolerances, material properties, bolt configurations, and installation procedures that must be followed to achieve optimal results. Compliance with recognized standards such as EN, AREMA, or JIS ensures interoperability and maintains safety margins throughout diverse operating environments.

Quality assurance programs verify that fishplates meet stringent performance requirements through comprehensive testing protocols including tensile strength verification, fatigue resistance evaluation, and dimensional accuracy assessments. Certified testing laboratories conduct standardized evaluations to validate fishplate performance under simulated operating conditions, ensuring that components will perform reliably throughout their intended service life. Adherence to established standards provides confidence in fishplate performance while supporting international trade and technology transfer.

Application-Specific Design Considerations

Different railway applications require specialized fishplate designs optimized for specific operating conditions, traffic patterns, and infrastructure requirements. Heavy freight railways demand robust fishplates capable of withstanding extreme axle loads and frequent loading cycles, while high-speed passenger lines require precision-manufactured components that maintain smooth track geometry at elevated operating speeds. Urban transit systems may prioritize noise reduction and vibration damping characteristics to minimize impacts on surrounding communities.

Selection criteria for fishplates must consider factors including rail profile compatibility, environmental conditions, maintenance access limitations, and long-term performance expectations. Railway engineers evaluate multiple technical parameters when specifying fishplates, including bolt hole positioning, bearing surface geometry, and material grade specifications. Proper selection ensures optimal performance while minimizing lifecycle costs and maintenance requirements throughout the component's operational period.

FAQ

What are the primary materials used in modern fishplate manufacturing

Modern fishplates are typically manufactured from high-carbon steel alloys that provide excellent strength, durability, and fatigue resistance. The most common material specifications include carbon steel grades with carbon content ranging from 0.40% to 0.70%, often incorporating manganese, silicon, and other alloying elements to enhance mechanical properties. Some specialized applications may utilize weathering steel or stainless steel variants for enhanced corrosion resistance in challenging environmental conditions.

How often should fishplates be inspected for safety compliance

Railway safety regulations typically require fishplate inspections at regular intervals ranging from monthly to annually, depending on traffic density, axle loads, and environmental conditions. High-traffic mainlines may require monthly visual inspections with detailed examinations performed quarterly, while lighter-traffic branch lines might operate on semi-annual or annual inspection schedules. Ultrasonic testing and other non-destructive evaluation methods are often employed during major inspections to detect internal defects or stress concentrations that could compromise safety.

What factors determine the service life of railway fishplates

Fishplate service life depends on multiple interrelated factors including material quality, installation precision, traffic loading, environmental conditions, and maintenance practices. High-quality fishplates installed according to manufacturer specifications can typically provide 15-25 years of reliable service under normal operating conditions. Factors such as heavy axle loads, frequent temperature cycling, corrosive environments, or improper bolt tensioning can significantly reduce service life and require more frequent replacement intervals.

Can fishplates be retrofitted to existing railway infrastructure

Yes, fishplates can typically be retrofitted to existing railway infrastructure, though compatibility considerations must be carefully evaluated. The retrofitting process requires matching fishplate specifications to existing rail profiles, verifying adequate clearances for installation equipment, and ensuring compatibility with current maintenance procedures. Successful retrofitting projects often involve gradual replacement programs that minimize service disruptions while upgrading infrastructure to modern safety and performance standards.