Understanding Conventional Railways Fasteners and Their Importance

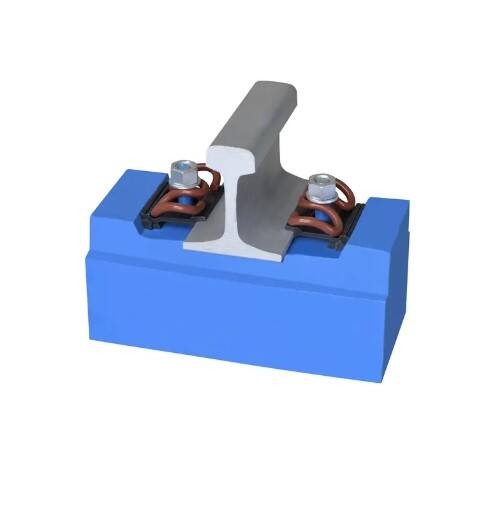

Traditional railway fasteners play a critical role in keeping train tracks stable and safe for everyday operations. Most systems rely on standard hardware including bolts, nuts, and those flat metal discs we call washers. When installed properly, these parts lock everything down so trains can run smoothly without shifting or coming loose over time. Bolts pass right through the holes already made in both rails and the wooden ties beneath them. Then workers screw on the nuts tight enough to stop any wobbling or movement during service. Don't forget those washers though they sit between the nut and bolt head to spread out pressure points. Without them, the metal would wear down faster from all that constant stress. This whole setup makes sure everything stays intact even after years of heavy usage by freight and passenger trains alike.

Rail fasteners do much more than just keep tracks where they belong. These small components actually hold together the whole railway network's safety and stability. When trains roll across the rails, fasteners work hard to stop them from shifting around while soaking up those annoying vibrations that would otherwise make for a rough journey. Passengers get a smoother ride, and the rails themselves last longer because they aren't constantly bouncing around. Properly working fasteners really matter for accident prevention too. Without them doing their job right, we'd see far more derailments and other dangerous situations on our railways every year.

Factors to Consider When Choosing Conventional Railways Fasteners

Choosing the right materials for standard railway fasteners really matters when it comes to how long they last and how well they work. Most often we see steel and aluminum being used, both offering different benefits depending on what's needed. Steel fasteners have this amazing strength that lets them handle a lot of pressure, so they're pretty much the go to choice for those tough jobs where things get really intense. The thing about steel is that it just doesn't give up easily over time, which explains why it stays reliable even under constant heavy loads from trains passing through day after day. Aluminum takes a different approach altogether. It weighs way less than steel, helping cut down on the total weight of everything put together on tracks. But there's always trade off here too since aluminum simply can't carry as much weight as good old fashioned steel can manage.

The ability to withstand weather is really important for how long railway fasteners last before they need replacing. When these components get exposed to things like rainwater and road salt, they start corroding pretty quickly which affects how well they hold everything together. One good solution we've seen work well lately involves applying special nano-coatings onto the metal surfaces. These coatings actually perform much better at stopping rust than regular paint jobs do. Some tests done in labs showed improvements around 300 times greater than what traditional methods offer. For areas where there's lots of sand blowing around, these nano coatings also shield against both physical wear from grit and chemical damage caused by salty air, meaning tracks stay secure for much longer periods between maintenance checks.

When picking fasteners for railway work, load capacity matters a lot alongside meeting performance standards. The bolts and clips need to handle massive weights from trains going over them again and again while keeping everything safe and structurally sound. Rail companies rely on manufacturers who stick to specs set by groups like EN in Europe or AREMA here in America. These guidelines make sure the fasteners can take what gets thrown at them during daily operations. Think about all those vibrations from wheels on tracks, plus sudden impacts when trains pass through curves or switches. Without proper fastening, whole sections could come loose. That's why most major rail projects specify certain grades of steel and coating requirements based on these industry benchmarks. Safety isn't optional in this business.

Essential Specifications for Fasteners in Railway Applications

Size and fit matter a lot when picking fasteners for rail systems. Get this wrong and things start breaking down faster than expected. We've seen cases where bad fits cause all sorts of problems from extra wear on parts to complete equipment breakdowns, sometimes creating real safety risks too. Think about what happens when those bolts just aren't quite right - they tend to vibrate loose after months of constant movement across tracks. This kind of failure isn't just annoying; it actually damages infrastructure over time. Rail companies spend millions fixing these preventable issues every year because someone overlooked basic sizing requirements during installation.

When looking at railway fasteners, certification and compliance standards matter a lot for real world applications. Rail operators know their fasteners need to meet tough requirements from organizations like ISO and ASTM if they want safe operations. These standards aren't just paperwork - they actually test whether fasteners hold up against things like extreme temperatures, vibration, moisture and corrosion that happen day after day on tracks across the country. Getting proper certification means these components last longer and perform reliably even under challenging conditions that would break cheaper alternatives within months.

The kind of fasteners used varies quite a bit between different rail systems based on what each application needs. Take high speed trains for example they need special fasteners that handle all those vibrations from going so fast plus changes in temperature as well. Regular train tracks on the other hand tend to focus more on fasteners that won't rust away over time since they're exposed to weather conditions day after day. Getting this stuff right matters a lot because it keeps the whole track system intact and running smoothly without unexpected breakdowns or safety issues down the road.

Evaluating Fastener Performance: Testing and Standards

Railway fastener performance needs proper evaluation, something that relies heavily on standard testing methods across the industry. The most common approaches are tensile strength testing to see how well fasteners hold up when stretched, along with fatigue testing that looks at how long they last when subjected to repeated stress over time. These assessments help confirm fasteners stay strong enough to handle all sorts of harsh conditions encountered in actual rail operations. Without them, there's a real risk of failure points developing somewhere down the line, which would not only compromise passenger safety but also cause major disruptions to train schedules and services.

Knowing the applicable standards and getting certified isn't just something to check off after testing either. Take EN 15048 for instance this one specifically deals with those non-preloaded structural bolts we see everywhere. These kinds of standards really matter because they establish baseline safety levels that everyone in the industry needs to follow. When fasteners pass these tests, it means they've been through proper evaluation processes so different companies can produce parts that work reliably together no matter where they come from. Following these guidelines makes the whole system safer in the long run. Railways especially depend on this kind of consistency since even small failures in bolt connections could lead to major problems down the track.

Maintenance and Replacement of Fasteners in Railway Systems

Keeping track of fastener conditions through regular inspections is really important for safe railway operation. Most engineers run their standard checkups looking at things like rust spots, bolts coming loose, or any kind of physical damage to the tracks. They pay special attention to parts like rail clips and those metal spikes that hold everything together, checking for wear marks or bends that might make them fail under stress. Without proper maintenance, these small but essential components can cause big problems down the line. The whole point of all this checking is to keep trains running smoothly without unexpected stops or worse safety issues caused by failing fasteners somewhere along the track.

Signs that fasteners need replacing generally come down to spotting visible wear or damage, particularly where environmental conditions speed things up. Think coastal regions with salt air or desert tracks where sand gets everywhere. When checking equipment, engineers look at how much rust has built up, whether bolts have bent out of shape, and if they still hold weight properly under stress. Getting rid of worn parts before they fail matters a lot for keeping trains running safely day after day. A good maintenance plan doesn't just stop accidents though it actually makes sense economically too because well maintained rails last longer without needing constant repairs or replacements down the road.

Conclusion: Making an Informed Decision on Fasteners

Picking suitable fasteners for standard railway tracks requires looking at a few important things like how long they'll last, what kind of weather they face, and whether they fit within budget constraints. Getting this right really matters because bad fastener choices can compromise both safety and smooth operation across rail networks. When companies evaluate materials used in these components alongside actual working conditions on different lines, they end up making better choices that actually extend track life and keep trains running reliably year after year without constant repairs.

FAQ Section

What are the key components of conventional railway fasteners?

Conventional railway fasteners typically include bolts, nuts, and washers that work together to hold rail tracks in place, ensuring the stability and safety of railway infrastructure.

Why is material selection important for railway fasteners?

Material selection is crucial because it influences the durability, strength, and weight of the fasteners, affecting the overall performance and safety of the railway infrastructure.

How do weather conditions affect railway fasteners?

Weather conditions, especially moisture and salt, can cause corrosion in fasteners, compromising their performance. Techniques like nano-coating enhance corrosion resistance, extending the lifespan of these fasteners.

Why are industry standards important for railway fasteners?

Industry standards ensure that fasteners meet necessary safety and performance criteria, providing reliability and consistency across various manufacturers and applications.

Table of Contents

- Understanding Conventional Railways Fasteners and Their Importance

- Factors to Consider When Choosing Conventional Railways Fasteners

- Essential Specifications for Fasteners in Railway Applications

- Evaluating Fastener Performance: Testing and Standards

- Maintenance and Replacement of Fasteners in Railway Systems

- Conclusion: Making an Informed Decision on Fasteners

- FAQ Section