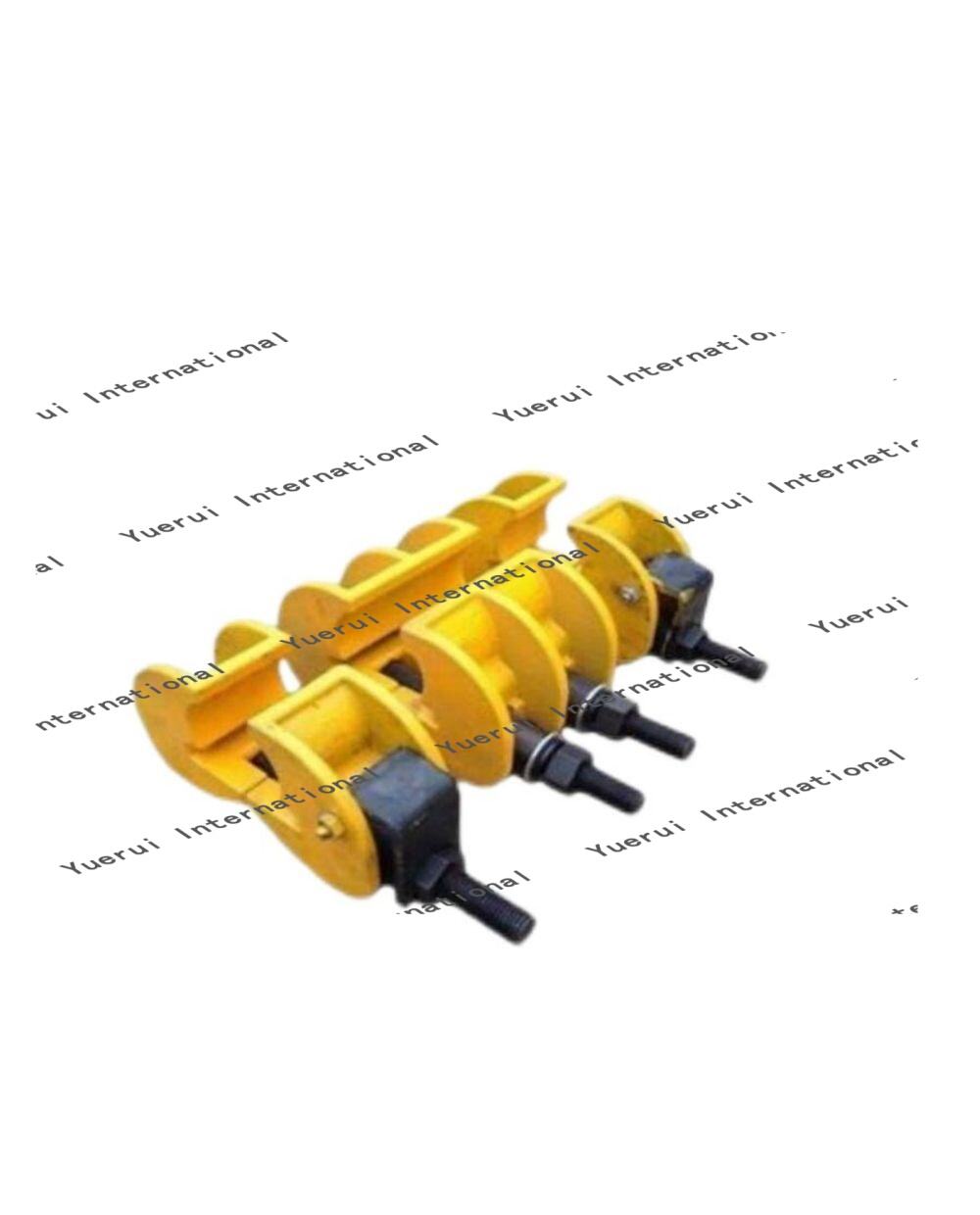

railroad tools

Railroad tools represent an essential category of specialized equipment designed for the construction, maintenance, and repair of railway infrastructure. These tools encompass a wide range of instruments, from basic hand tools to sophisticated mechanical and electronic devices. The primary functions include track laying, rail alignment, fastening system installation, and ongoing maintenance operations. Modern railroad tools often incorporate advanced technologies such as laser guidance systems for precise measurements, digital displays for accurate readings, and ergonomic designs for improved worker safety and efficiency. These tools are engineered to withstand the demanding conditions of railroad environments, featuring heavy-duty construction materials and weather-resistant coatings. Key applications include rail joint maintenance, tie replacement, track geometry adjustment, and ballast profiling. The tools are designed to meet strict industry standards and safety regulations, ensuring reliable performance in critical railway operations. Many contemporary railroad tools also feature modular designs for easy maintenance and replacement of parts, reducing downtime and extending service life.