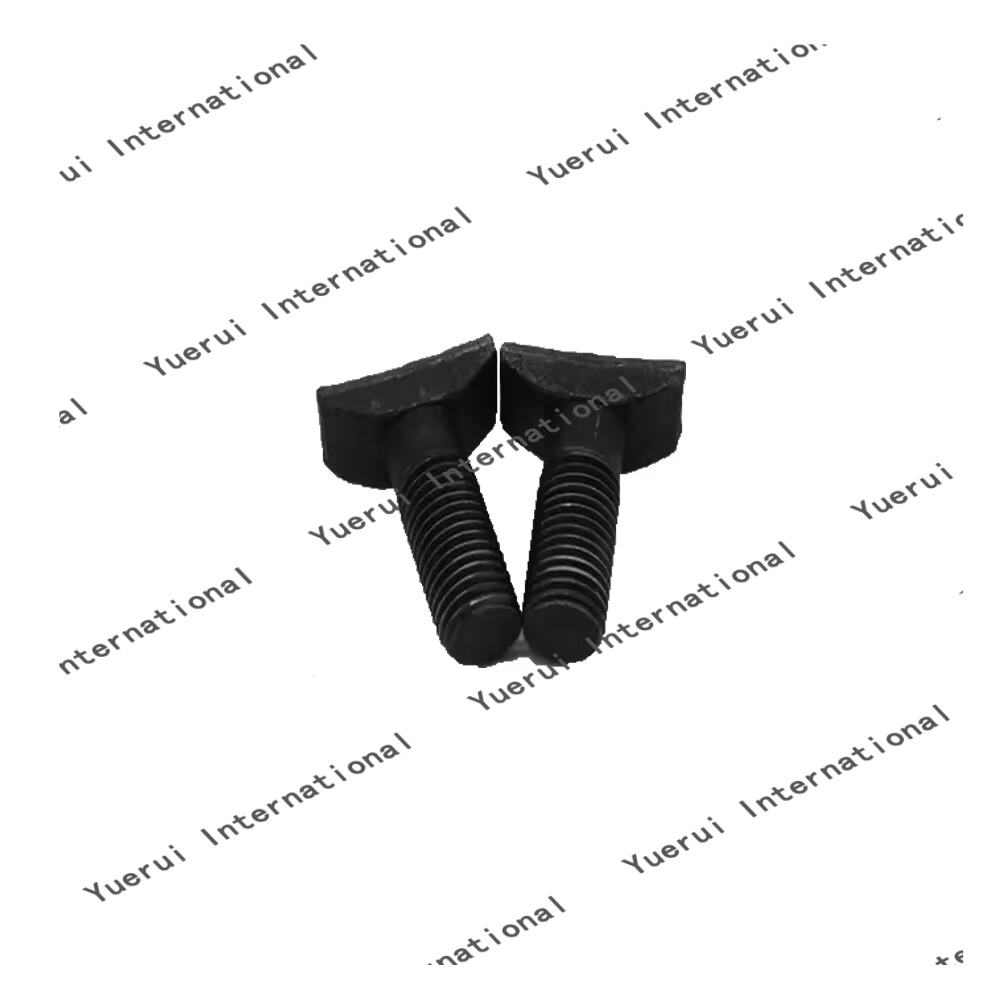

square head bolts and nuts

Square head bolts and nuts represent a classic and robust fastening solution that has stood the test of time in industrial applications. These fasteners feature a distinctive square-shaped head design that provides enhanced grip and torque capabilities, making them particularly valuable in heavy-duty construction and machinery applications. The square head configuration allows for easier wrench engagement and superior torque application, especially in situations where power tools may not be practical or accessible. These fasteners are typically manufactured from high-grade steel and often feature various protective coatings to enhance their corrosion resistance and durability. The square design of both the bolt head and nut creates a larger surface area for tool contact, which significantly reduces the likelihood of slippage during installation or removal. This makes them especially suitable for applications where maintenance and adjustments are frequently required. The robust construction of square head bolts and nuts makes them ideal for structural connections in timber construction, heavy equipment assembly, and agricultural machinery. They are available in various sizes, thread patterns, and material grades to accommodate different load requirements and environmental conditions.