The Critical Role of High-Speed Railway Fasteners in Train Safety

Why Fasteners Are Essential for High-Speed Rail Stability

Fasteners are vital structure part of the track, especially to the high-speed railway tracks. They are contribution for rail stability during fast travel and help preventing serious accidents this way. These fasteners are both shear and tensile and designed to take dynamic loads, which is crucial because of the forces that bolts and studs must endure in a high-speed engine. Rail joint failure, for which insufficient fastening systems are the main cause, may, under the most adverse cases, lead to the derailment.

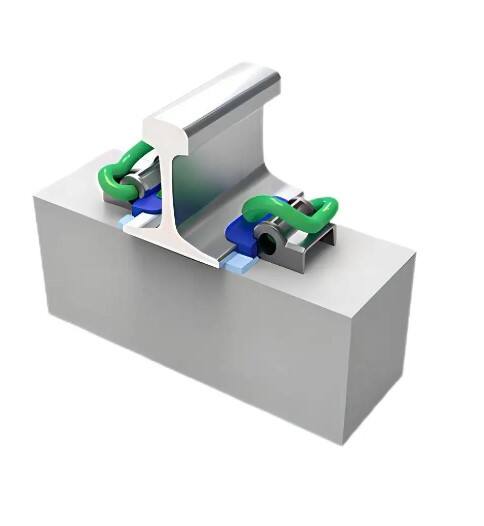

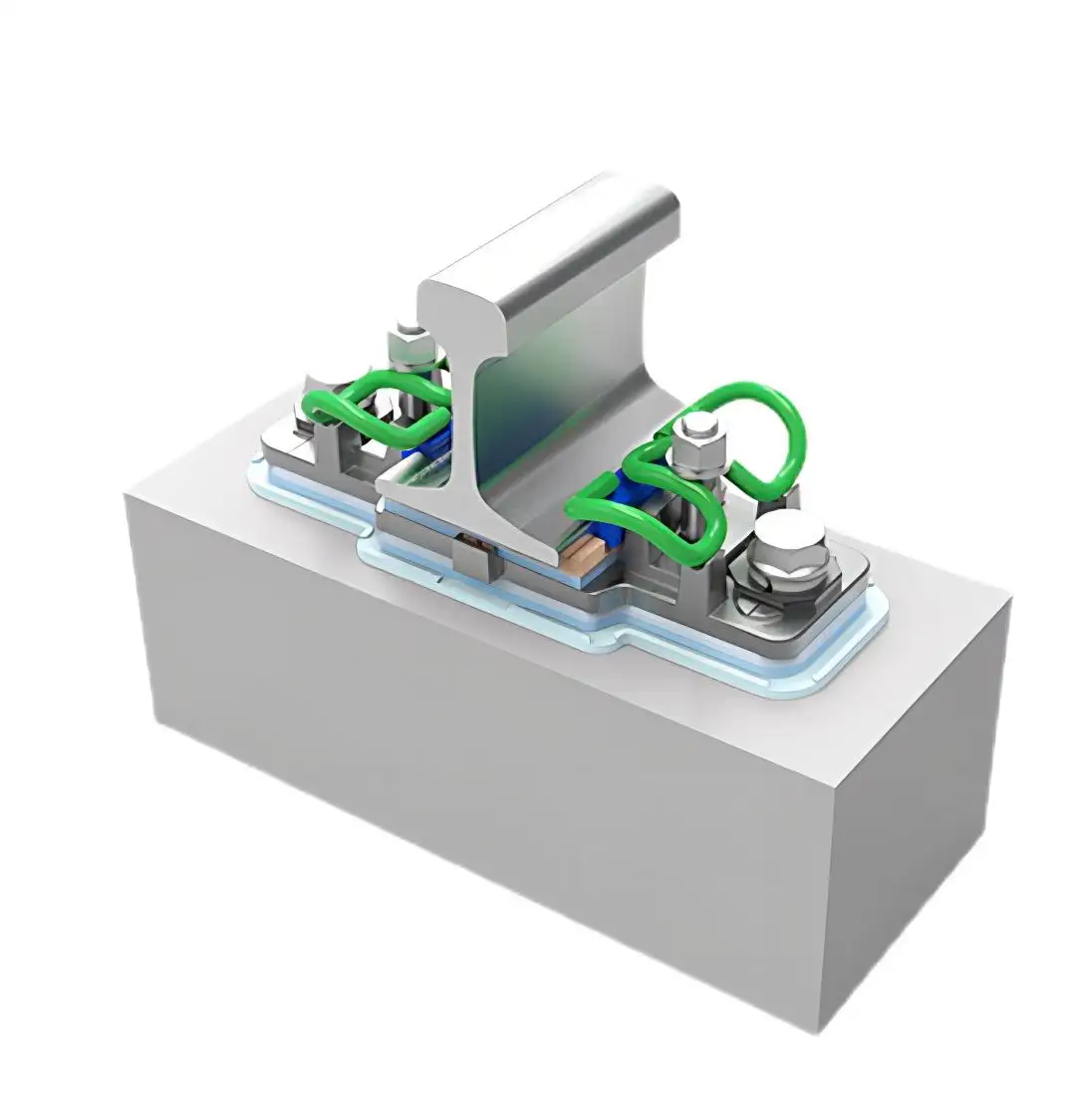

- Types of Fasteners: Different types of fasteners such as bolts, screws, clips, etc. are explicitly designed for the railway applications to comply with the safety requirements. These parts are produced to secure rails to sleepers or other track elements, thereby stabilising and aligning them. Such correctly designed fasteners are critical to rail safety programs as derailment probabilities are greatly increased because of the absence of such fasteners. For example, Pandrol has developed specialty fasteners that are capable of vertical and lateral adjustments, helping to maintain rail integrity in non ballasted tracks.

How Fasteners Prevent Track Deformation at Extreme Speeds

Fastening systems are intended to help to prevent track buckling, which is a critical safety issue in high-speed rail systems. When the speed of trains is very high, track misalignment can be caused due to the magnitude of the forces acting on the track without an adequate fastening system. Studies suggest that the poorly formed railfasteners(2) contribute to such problems, thus hampering the traffic of trains and their safety. To ensure this, all fasteners are constructed to be flexible and strong to absorb impacts without stripping and wearing out.

- Advanced Railway Fastener Technology: track deformation is less in some countries using advanced fastener technology. These fasteners provide safety as well as excellent performance to the total system by taking care of the alignment of the track against the high stress. The Loadmaster Direct Fixation track fastener from Progress Rail is one example of such a development and provides solutions to the loads that are caused to a supporting structure as forces are transferred – significantly increasing the component life of a railway.

These discussions underscore the vital role high-speed railway fasteners play in ensuring the safety and reliability of train operations. Their ability to maintain rail stability and prevent track deformation is crucial for the safe and efficient operation of high-speed rail networks globally.

Material and Design Innovations in High-Speed Railway Fasteners

Advanced Alloys for Durability and Corrosion Resistance

The application of new materials (such as high performance steel, etc.) and new technologies of advanced material (as elastic rail clip of ADI (Austempered Ductile Iron, etc.) have improved the safety and long-term stability of heavy haul rail fasteners. These materials are made to endure the harsh environment of the railway—the factors high moisture and fluctuating temperatures are everyday occurrences. Anti-corrosive quality is especially important due to the high moisture and humidity conditions that most outdoor furniture is exposed to. This directly relates to how long the bolt will last. As research has shown, the use of corrosion-resistant materials could reduce maintenance costs by as much as 30% and they are a cost effective solution in ensuring the rail network remains safe in the long term. Moreover, there’s more and more of a focus on using lightweight, yet strong materials in the development of fasteners. This not only simplifies handlers´ work during the installation process but it also supports more efficient train operations.

Ergonomic Designs to Minimize Vibration and Noise

Today, ergonomic design of rail fastening systems also contributes a significant impact in reducing vibrations and noise caused by high-speed train running. Vibrations may lead to wear of the track components and consequently to reduced service life. Therefore, ergonomic design is necessary to provide long-term reliability and performance. According to research these advanced designs can reduce vibrations by 40% and in turn are an important factor in the comfort of passengers. It's heartening that manufacturers are themselves spending a great deal of time on developing bolts that serve necessary operational conditions but also, in some small way, help to build quieter railway systems. This thrust for ergonomic innovation in transportation is synchronized with a worldwide tendency to endeavor efficient and environmental safe transport.

Addressing Unique Stresses in High-Speed Rail Applications

Aerodynamic Challenges at 300+ km/h Speeds

High speed trains have their individual aerodynamic requirements, which require specific fastener designs to hold its aerodynamics like stability and control. Because of the high speed range which train operates (300 km/h), the effect of aerodynamic forces on train operation may become critical and it is very much important to concentrate on the design strategies for optimization. Fastener manufacturers take great care to reduce drag with aerodynamic style fasteners to maximize efficiency. And the potential advantages of better aerodynamics are huge, with some figures suggesting fuel economy could be boosted by up to 15 per cent. This illustrates the need for fastener technology to continually evolve. Furthermore, continuous aerodynamic force testing and modeling is necessary for the optimal design of fastener structures, in order to satisfy the strict requirements of HSR.

Fatigue Resistance for Long-Term Reliability

Fatigue resistance is of paramount importance in the long-term reliability of fasteners in the context of high-speed rails. These properties need to resist cycle bycycle loading and unloading, from which the material could fatigue otherwise. To deal with this, ambitious testing trials are currently being executed to prove that fasteners continue to perform and are safe for use over a long time period. Data from these tests demonstrate that crack propagation can make a significant contribution to the useful life of a fastener and that the life to propagation can be increased by specialized coatings and treatments. It is very important to comply with industry standards, which require intensive fatigue load testing, to ensure that fasteners meet stringent safety and reliability standards to maintain safe operation of railroads.

Optimizing Rail Networks Through Advanced Fastener Technology

Predictive Maintenance Using Smart Fastener Systems

By adding smart technology into fasteners, fasteners can be monitored in real time, a potential game changer in predictive maintenance strategies for railway industry. Reacting in real time, such intelligent systems can predict when something might fail in the days or weeks before it actually does with the result that down time and the cost of maintenance are minimized. Big Data can be beneficial Here evidence-based decision-making can make a difference: it can in fact extend the working life of railway infrastructure by 20%, significantly promoting the idea that technology is exploitable. This move towards smart fastener solutions reflects the industry-wide migration toward digitalization of rail systems, and establishes a new benchmark for operational efficiency and availability.

Sustainability in Fastener Manufacturing and Recycling

Sustainability is turning out to be a key aspect in high-speed railway fasteners manufacturing, with a focus on environmentally friendly materials and processes. It’s also cutting waste and supporting a circular economy, which is something the likes of rail transportation are working towards. Sustainable practices not only help the environment, but also lower long-term production costs -- a significant double whammy, according to recent evidence. And maybe for the same reason, a few forward thinking leaders in the industry are championing the cause of recyclable materials in fastener production, enabling for original innovation and allowing for a greener future.

FAQ Section

What are high-speed railway fasteners?

High-speed railway fasteners are components used in rail systems to secure rails to their supporting structures, ensuring stability and safety at high-speed travel.

Why is the material of railway fasteners important?

The material of railway fasteners is crucial for durability, corrosion resistance, and the ability to withstand high-speed and environmental stressors, ultimately ensuring safety and cost-effectiveness.

How do smart fastener systems contribute to railway safety?

Smart fastener systems enable real-time monitoring of rail conditions, which aids in predictive maintenance and reduces potential failure costs, thus enhancing overall safety.

What are the aerodynamic challenges faced by high-speed trains?

High-speed trains face aerodynamic challenges such as drag, which can affect performance. Efficient fastener designs help minimize these challenges, improving efficiency and control.

How does sustainability impact fastener manufacturing?

Sustainability in fastener manufacturing reduces environmental impact and production costs by using eco-friendly materials and promoting recycling, supporting a circular economy.