Core Components of High-Speed Railway Fastening Systems

Traditional vs. Modern Fastener Design Principles

Old school railway fastening systems mostly stuck to simple designs and basic materials because they focused on getting the job done without breaking the bank. They worked fine for regular trains back in the day, but started showing their age when faced with the demands of high speed travel since they couldn't really cope with those intense dynamic forces. Fast forward to today and things look completely different. Modern fastener designs for high speed rail have come a long way, incorporating stuff like super strong alloys and cleverly engineered plastics into the mix. What this means is stronger parts that can take more punishment while actually weighing less than their predecessors. Lighter components translate to better performance across the board for railway systems trying to keep up with ever increasing speed requirements.

Modern fastener designs actually take into account various track conditions as well as different types of loads that they need to handle. Take it this way these systems have been crafted carefully to offer better stability and keep things safe even when trains are moving at really high speeds. The fasteners we see nowadays incorporate advanced engineering techniques that help them cope with temperature changes throughout the day, which keeps the rails aligned properly without issues. Moving away from older fastening methods has definitely made a big difference for high speed rail systems across the board. We're seeing better performance overall, longer lasting components, and most importantly improved safety measures for passengers traveling at those incredible velocities.

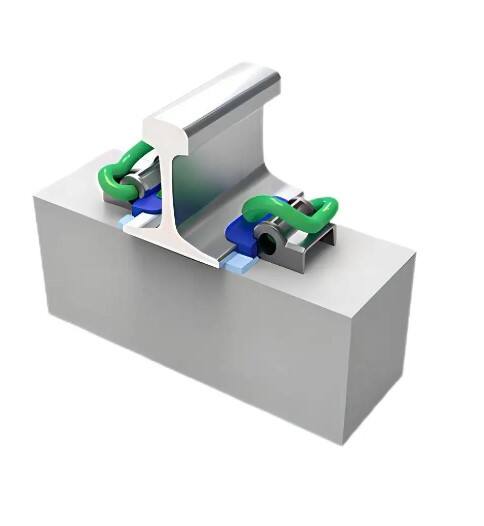

Key Elements: Tension Clamps and Rail Pads

Tension clamps play a really important role in keeping rails aligned when trains pass over them at high speeds. These devices apply steady pressure against the rail tracks, stopping them from shifting sideways or bouncing up and down which would otherwise create dangerous conditions for passengers. What makes these clamps so effective is their ability to hold the correct distance between rails (known as track gauge) without requiring frequent adjustments by maintenance crews. This means fewer disruptions during regular service checks and ultimately leads to much safer train journeys across the network.

Rail pads help absorb shocks and cut down on vibrations in train tracks. Made mostly from rubber-like materials, they sit between rails and sleepers. Their main job is to soak up those annoying vibrations while keeping noise levels down something that matters a lot for passenger comfort and also helps protect the whole railway system from wear and tear. Studies indicate that getting the right balance between tension settings and pad materials makes a real difference in how well everything works together, spreading out those powerful forces across the track better and making it last longer before needing repairs. Getting these details right pays off big time when looking at long term expenses since proper installation means fewer breakdowns and smoother running trains overall.

Modular Systems for Diverse Track Applications

Modular fastening systems have really changed the game when it comes to adapting tracks for all sorts of setups. What makes these systems special is their ability to swap out parts and rearrange them according to what's needed on site. For instance, railroad companies often need different configurations depending on where they're laying tracks. The real advantage shows up in areas with varied geography and weather conditions. Tracks running through places with extreme temperatures or different types of ground need adjustments to handle local challenges. Some sections might require stronger fastenings for rocky terrain while others need flexibility for sandy soils. This kind of adaptability saves time and money compared to traditional methods that required completely new installations for each situation.

Looking at actual implementations across different parts of the world shows just how well modular systems work in practice. These systems handle track laying in some pretty tough environments too—from blistering hot deserts where temperatures soar past 120°F to icy tundra regions where snow covers everything for months on end. What makes them stand out? Well, they're surprisingly easy to put together and maintain. When something needs fixing or adjusting, crews can get right to work without waiting days for specialized equipment. This cuts down both time spent offline and what companies pay in labor expenses. Railway operators today need infrastructure that keeps running smoothly year after year while standing up to whatever Mother Nature throws at it, which is exactly what these modular approaches deliver.

Engineering Breakthroughs in Fastener Technology

Magnetorheological Elastomer (MRE) Material Innovations

Magnetorheological elastomers or MREs are changing the game when it comes to fastening systems on high speed railways. What makes these materials special is their ability to adjust on the fly to different conditions, responding specifically to whatever environmental or operational challenges come up. The benefits speak for themselves really good vibration damping and amazing impact resistance properties that matter a lot for keeping trains safe and running smoothly at those blistering speeds. Industry studies show that companies using MREs in their fastening systems report better durability and overall stability compared to older methods. This suggests we might see a complete overhaul of how train components stay attached as manufacturers continue testing these smart materials.

Vossloh Protect: Advanced Corrosion Resistance

The Vossloh Protect technology represents a major step forward when it comes to making railway fasteners last longer thanks to its excellent resistance against corrosion. The coating works wonders for high strength steel parts, keeping them intact even when exposed to all sorts of weather conditions from scorching heat to freezing cold. Real world tests conducted in various regions around the globe have shown just how well this tech stands up against rust and degradation over time. More and more companies are starting to adopt Vossloh Protect these days because it changes how maintenance is handled. Rail operators find themselves spending less money on fixing things up so often since they don't need to replace worn out components as frequently anymore. This means better planning for routine maintenance schedules without unexpected breakdowns disrupting operations.

Precision Manufacturing with Structured Light Sensors

Structured light sensors are really important for making sure railway fasteners meet exact standards during manufacturing. These advanced tools help factories measure fastener dimensions much more accurately than traditional methods, which means better fitting parts that work safer in actual train tracks. When companies get this level of precision right, they save money over time because there's less waste and fewer replacements needed down the road. Factory data shows pretty impressive results too – some plants report cutting down on defective products by around 30% after switching to structured light technology. This kind of improvement matters a lot when we're talking about something as critical as rail infrastructure components that need to hold up under extreme conditions day after day.

Enhancing Safety Through Vibration Control

Force Distribution Mechanics in Slab Track Systems

How forces get distributed across slab track systems really matters when it comes to keeping the whole track system intact, particularly important for those fast moving trains we see today. Good design work here makes sure all those powerful forces from passing trains spread out properly over the whole infrastructure instead of putting too much pressure on just one part. Bad designs sometimes create problem spots where too much weight concentrates, which eventually leads to breakdowns down the road. Looking at actual field data shows us that getting this load balancing right cuts down on wear and tear quite a bit, meaning longer lasting tracks and safer rides overall. Take for example what happened on one European high speed railway line recently. After they upgraded their slab track system with better force distribution features, maintenance crews reported around a quarter less spending on repairs compared to before the upgrade.

Reducing Micro-Crack Propagation in Concrete Sleepers

Tiny cracks forming in concrete railroad ties pose serious risks to track stability and overall rail safety. Over months and years, these little fractures tend to grow bigger, particularly when subjected to the relentless pounding from heavy freight trains that pass through daily. Engineers have come up with various fixes for this problem, including better materials mixed into the concrete and smarter ways to distribute pressure across the tie's surface. Some recent innovations involve adding microscopic reinforcement elements within the concrete itself, which helps slow down how fast those cracks spread. A case study conducted in Japan showed pretty impressive results too - around 40% fewer cracks appeared in test sections where these new methods were applied. This means safer rails for everyone and far less chance of dangerous derailments caused by failing infrastructure.

Case Study: Derailment Prevention in Heavy Haul Lines

Looking at past derailments tells us why good fastening systems matter so much for keeping trains on track. One real world example comes from a heavy freight line where better fastenings made all the difference in preventing derailments. After an incident happened there, investigators found out that newer fastener technology cut down on similar problems happening again. Rail operators who switched to modern materials saw their accident rates drop dramatically. Take one company that installed these improved systems across its network - they noticed around a third fewer derailments within just six months. All this shows that investing in solid fastening systems isn't just about meeting regulations anymore. It actually saves money long term while making sure passengers and cargo stay safe during transit.

Operational Efficiency Improvements

Enabling Continuous Welded Rail Implementation

The introduction of Continuous Welded Rail (CWR) systems has changed how railways operate today, making trains run better while saving money on repairs. By getting rid of those pesky rail joints, tracks become much smoother, so there's less need for constant fixing and passengers actually enjoy their rides more. Without all those joints knocking against each other, the rails don't wear down as fast from the constant hitting, which means lower repair bills in the long run. Look at Europe's railroads - when they switched to CWR, many saw their maintenance costs drop around half, which makes operations way more efficient. Better riding comfort isn't just good for customers; it also cuts down on noise pollution from trains rumbling along the tracks, resulting in a calmer surrounding for nearby communities. With sustainability becoming increasingly important, these benefits show why CWR remains such a smart choice for railway companies looking to build infrastructure that lasts longer without breaking the bank.

Maintenance-Free Solutions for Reduced Downtime

Switching to maintenance free fasteners across railway systems can really help cut down on downtime while boosting overall efficiency. These modern fastening solutions incorporate special materials and tech innovations including those self lubricating properties that dramatically reduce how often maintenance crews need to check them out and spend money on repairs. When there's less friction between parts thanks to those self lubricating materials, components just last longer before wearing out completely. Take certain rail lines that started using these no maintenance options last year they saw their downtime drop around 30% give or take depending on conditions. Mechanics working on these tracks report not only saving cash but also noticing better safety records since workers don't have to climb around trains so frequently for routine checks anymore. The whole approach seems pretty promising for keeping trains running smoothly without unexpected delays disrupting schedules.

Energy Savings Through Optimized Load Transfer

When railway systems get better at moving weight around properly, they open up big chances to save on energy use. Think about how trains actually work their way along the tracks. Good load transfer means less wasted power and longer lasting parts on both the train wheels and the rails themselves. Some studies point to energy savings of around 20% when these improved designs are put into practice, which adds up to serious money saved over time for railway operators. Look at what's happening across Japan and throughout Europe where many rail networks have already adopted these smarter approaches. They're seeing real drops in running costs while keeping services reliable. Beyond just saving cash, these improvements help cut down on carbon emissions too since less energy gets burned unnecessarily. We're starting to see this become standard practice in the industry as companies try to meet sustainability targets and respond to growing concerns about climate change impacts.

Global Adoption and Performance Validation

European High-Speed Network Standards (EN/AREMA)

European high speed trains follow strict rules set by standards such as EN and AREMA, and these really shape how rail fasteners are designed and perform. The point of all these regulations is simple enough they make sure train parts are safe and efficient, so passengers get reliable service when they need it most. Take safety improvements for example. When companies stick to these guidelines, accidents drop off dramatically while repairs become less frequent, saving money in the long run. Looking at real world numbers across different countries shows pretty impressive results too. Most European rail operators report better performance metrics after implementing these standards properly, something that makes sense given how thoroughly they're applied throughout the industry.

Japan's Shinkansen Fastener Evolution Since 1964

When Japan launched the Shinkansen back in 1964, nobody could have predicted how much fastener technology would change over time. These small but essential components have been central to making the bullet train faster, safer, and longer lasting throughout its history. Engineers kept improving fastener designs decade after decade, creating stronger parts that can handle extreme speeds without compromising passenger safety. For instance, modern fasteners now incorporate special materials that resist wear even at high velocities. Looking at industry reports, it's clear these upgrades made a real difference in day-to-day operations. Trains experience fewer unexpected stops and require less frequent maintenance checks than they did in earlier years, which means better service for passengers across the country.

China's 50 Million Annual Tension Clamp Production

With an annual output of around 50 million tension clamps, China plays a major part in supplying parts for high speed trains worldwide. When making so many components, maintaining consistent quality becomes absolutely critical. Manufacturers implement strict checks throughout production to make sure every single clamp performs reliably under stress conditions. These quality controls match industry standards set across different countries. Looking at actual export figures tells another story too. Chinese made tension clamps consistently hit or even surpass international specs, which explains why they keep showing up on railway projects from Europe to South America. The growing demand speaks volumes about how well these products stack up against competition from other regions.

Future Trends in Adaptive Fastening Systems

Smart Fasteners with Real-Time Geometry Monitoring

The latest smart fastening systems with real time geometry monitoring tech are changing how we think about railway safety and performance. These systems actually use structured light sensors to measure things like track alignment and component wear with incredible accuracy. This kind of precision allows engineers to spot problems before they become serious issues, which cuts down on failures significantly. A study back in 2018 by researchers at the University of Shanghai (published in Sensors) found that tracks equipped with these smart fasteners lasted longer and had fewer accidents compared to traditional setups. When maintenance crews get this constant stream of data from the tracks themselves, they can fix small problems quickly instead of waiting for bigger breakdowns. This means trains run smoother, passengers experience fewer delays, and operators save money on emergency repairs.

[1]Cui, H., Hu, Q., & Mao, Q. (2018). Real-Time Geometric Parameter Measurement of High-Speed Railway Fastener Based on Point Cloud from Structured Light Sensors. Sensors, 18(11), 3675. https://doi.org/10.3390/s18113675

Sustainable Materials for Reduced Carbon Footprint

Using eco-friendly materials for fastening systems offers real environmental advantages, especially when it comes to cutting down on carbon emissions. When companies start incorporating stuff like recycled aluminum or bio-based plastics into their fastening solutions, they actually make a dent in the carbon footprint associated with building and maintaining high speed railways. Take a look at what happened with those deconstructed tire rail pads mentioned in a study by Sol-Sánchez and others published in Construction and Building Materials. That particular application showed just how much better things can get environmentally when we switch to greener options. The rail industry isn't just making trains faster anymore – by swapping out traditional materials for sustainable alternatives, this sector stands to become one of the key players fighting back against climate change across transportation infrastructure.

[2]Sol-Sánchez, M., Moreno-Navarro, F., Rubio-Gámez, M.C. (2015). The use of elastic elements in railway tracks: A state of the art review. Construction and Building Materials, 75, 293-305. [Google Scholar] [CrossRef]

Integration with Maglev Track Compatibility

The combination of adaptive fastening systems with Maglev tech is set to make big strides in transport efficiency. Magnetic levitation works differently from conventional rails, creating some pretty tough engineering problems that need special hybrid fasteners to bridge the gap between old and new systems. Researchers have been looking at this crossover for years now. A study published recently in pavement engineering journals shows just how viable these mixed systems can be when properly designed. While there are definitely efficiency gains to be had, real world implementation will require careful planning and substantial investment before we see widespread adoption across high speed rail networks in coming decades.

[3]Freudenstein, S. (2010). Rheda 2000®: Ballastless track systems for high-speed rail applications. Int. J. Pavement Eng., 11, 293-300. [Google Scholar] [CrossRef]

FAQ

What materials are typically used in modern railway fasteners?

Modern railway fasteners use advanced materials like high-strength alloys and engineered plastics, enhancing tensile strength and reducing weight.

Why are tension clamps vital in high-speed railway systems?

Tension clamps maintain rail alignment by exerting constant pressure, preventing lateral or vertical movement, essential for stable high-speed travel.

How do modular fastening systems benefit diverse track applications?

Modular systems offer adaptability by featuring interchangeable components tailored for specific track environments, accommodating different geographic and climatic conditions.

What advantages do Magnetorheological Elastomers (MRE) offer in fastening systems?

MREs provide improved vibration control and impact resistance, adapting to varying conditions while enhancing safety and efficiency.

How does Vossloh Protect technology enhance fastener longevity?

Vossloh Protect ensures superior corrosion resistance in fasteners, maintaining steel integrity across diverse climates, reducing repairs and replacements.

In what ways do smart fasteners improve railway safety?

Smart fasteners offer real-time geometry monitoring, enabling predictive maintenance and reducing failure risks, thus enhancing safety.

Table of Contents

- Core Components of High-Speed Railway Fastening Systems

- Engineering Breakthroughs in Fastener Technology

- Enhancing Safety Through Vibration Control

- Operational Efficiency Improvements

- Global Adoption and Performance Validation

- Future Trends in Adaptive Fastening Systems

-

FAQ

- What materials are typically used in modern railway fasteners?

- Why are tension clamps vital in high-speed railway systems?

- How do modular fastening systems benefit diverse track applications?

- What advantages do Magnetorheological Elastomers (MRE) offer in fastening systems?

- How does Vossloh Protect technology enhance fastener longevity?

- In what ways do smart fasteners improve railway safety?