Understanding High-Speed Railway Fastener Fundamentals

Components of Rail Fastening Systems

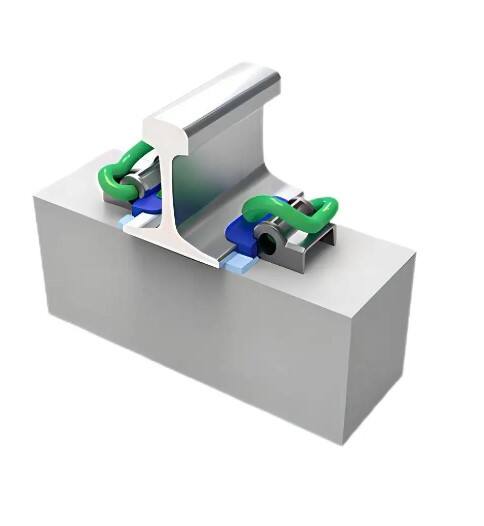

A good rail fastening system includes several key parts working together sleepers, clips, and bolts all built to handle the serious stress of high speed train operations. Sleepers themselves are typically constructed from tough stuff like concrete or special composites, acting as the foundation that keeps everything stable on the tracks. The clips used here come in different materials, mostly high strength steel or certain polymer blends, and their job is simple but vital they keep the rails locked down tight against the sleepers so nothing moves around when trains pass by at those crazy speeds. Bolts play their part too, generally made from heavy duty steel stock because they need to stand up against all that force without giving way. When putting this whole system together, precision matters a lot. Engineers spend countless hours making sure each component lines up just right, since even small misalignments can cause big problems over time as vibrations build up and trains zoom along the tracks at breathtaking velocities.

Why Fastener Integrity Impacts Rail Safety

Rail fasteners matter a lot when it comes to keeping trains running safely along the tracks, something railway safety data has shown time and again. When these fasteners fail, whether from wear or poor maintenance, they can actually cause derailments which puts everyone at risk. Think about it - if bolts come loose or clips aren't properly tightened, parts might just fall off while the train is moving, leading to serious problems down the line. The German rail company Deutsche Bahn ran some safety checks across their high speed network recently, and what did they find? Fastener issues were right up there among the top concerns for accident prevention. That's why civil engineers spend so much time checking every single connection point. They don't just look at things once in a while either; regular inspections are part of daily operations to make sure nothing slips through the cracks before it becomes a disaster waiting to happen.

Key Stress Factors: Vibration, Load, and Speed

The fasteners used in railway tracks face constant strain from train vibrations, both static weight and moving loads, plus the sheer speed of modern rail traffic. All these elements put serious pressure on materials, so engineers need fasteners strong enough to keep everything intact despite all that stress. Most manufacturers look at real world performance numbers and apply tried engineering methods when developing fasteners that stand up against these relentless forces. Take Nord-Lock's wedge locking washers for example they were designed right from the start to handle those tricky side-to-side forces that cause regular fasteners to work loose after months or years of service. Getting the design right through rigorous testing matters a lot because today's high speed rail systems demand components that won't fail unexpectedly, something critical for maintaining safe operations on rail lines around the world.

Common Maintenance Challenges with High-Speed Fasteners

Loosening Mechanisms from Dynamic Forces

When high speed trains move along tracks, they create powerful forces that can actually cause fasteners to come loose over time, making maintenance a big headache for engineers. We saw this happen back in 2010 with a Deutsche Bahn train accident. A door literally flew off because its fasteners failed while passing through a tunnel, leading to a collision with another train. To fix problems like this, engineers have started using special washers called wedge lock washers (Nord-Lock is one brand). These aren't your ordinary washers though. They're specifically engineered to stay tight even when subjected to all those constant vibrations and movements from train travel. The difference makes a world of difference for keeping train components securely fastened, which obviously matters a lot for passenger safety on our railways.

Fatigue Fractures and Material Degradation

When fasteners experience fatigue fractures, it's usually because they've been subjected to repeated stress cycles that gradually wear down the material over time. Stainless steel is commonly found in many fastener applications, but even this durable material has its limits and a certain lifespan that needs factoring into regular maintenance plans. Take for example what happens when components stay under constant stress conditions longer than planned - their actual durability drops off much quicker than anyone would expect. To catch these issues before they become major problems, engineers rely on various monitoring techniques including strain gauges along with looking at past failure records. These approaches help predict when fatigue might strike so maintenance crews can step in before anything breaks down completely.

Corrosion in Coastal and Extreme Environments

Moisture and salt content in the air are major culprits behind fastener corrosion, particularly problematic for structures located near coastlines or in harsh climates such as parts of Canada's northern regions and Australia's tropical zones. Studies from engineering firms have shown how corrosion eats away at metal connections over time, which can compromise structural safety and make maintenance schedules unreliable. The rail industry has responded by incorporating stainless steel components and applying specialized protective coatings to fasteners used in high speed trains. These material upgrades provide real world protection against degradation, keeping critical connections intact even when exposed to relentless weather conditions year after year.

Essential Maintenance Practices for Longevity

Torque Calibration and Tension Monitoring

Getting the right torque calibration and keeping an eye on tension levels matters a lot when it comes to those fasteners holding together high speed trains. When the torque and tension numbers are off just a bit, fasteners can fail because of all the constant movement and vibration from passing trains. Big rail companies across Europe have put together their own maintenance routines based on industry standards for setting proper torque levels. Take Britain's Rail Standards for instance they specify exact torque figures needed for different kinds of fasteners depending on where they're installed and what kind of stress they face daily. New tech stuff like digital torque wrenches and those fancy smart sensors makes life easier for maintenance crews. These gadgets give instant feedback about whether bolts are tightened correctly or not, which cuts down on mistakes during routine checks and saves time in the long run.

Lubrication Protocols for Moving Parts

Getting the lubrication right makes all the difference for keeping railway fasteners working properly over time. When parts move against each other without enough oil, they start wearing down faster than normal. That's why rail companies spend so much time figuring out what kind of grease works best where. Some places need special synthetics because regular oil just doesn't cut it when temperatures swing from freezing nights to hot days or when there's constant moisture around tracks. Most maintenance crews these days are switching to automated greasing systems instead of manual applications. These machines put just the right amount of lubricant exactly where it needs to go, which means bolts stay tight longer and trains keep running on schedule without unexpected breakdowns along the way.

Debris Removal and Surface Cleaning Techniques

Clean fastening surfaces matter a lot when it comes to stopping early wear and making sure railway fasteners last longer. When dirt and grime build up, they cause corrosion and extra friction which basically ruins how well the fasteners work. Most folks in the business use things like high pressure air jets and special brushes to get rid of all that junk stuck on there. The maintenance manuals usually recommend adjusting cleaning schedules depending on what's happening outside too. If there's been a lot of rain or snow recently, crews need to check those surfaces more often. Sticking to this kind of schedule keeps everything running smoothly for longer periods between replacements.

Advanced Diagnostic and Repair Strategies

Ultrasonic Testing for Internal Flaws

Ultrasonic testing now plays a key role in finding internal problems with fasteners on high speed trains, cutting down chances of things going wrong during operation. The technique sends out high frequency sound waves which can spot defects inside these components that nobody would ever see just by looking at them. This makes all the difference when it comes to avoiding disasters like train derailments. Take one real world example where a rail company actually found a serious problem thanks to ultrasonic checks, stopping what could have been a major accident. Newer versions of this technology are getting better at spotting issues faster too. Train operators can check their fasteners quicker than before and decide what needs fixing. As technology keeps improving, rail networks stay safe without breaking the bank on maintenance expenses.

Vibration Pattern Analysis for Early Issue Detection

Looking at vibration patterns helps spot fastener failures before they happen by finding weird spots in the normal vibration signals. Rail companies have found that catching these issues early makes their high-speed trains much safer and keeps them running reliably day after day. Some recent field tests actually showed clear links between certain strange vibrations and real fastener problems down the line. Portable vibration analyzers are becoming common tools across many rail networks now, letting engineers check these patterns all the time while trains run. When maintenance crews fix small problems based on these readings instead of waiting for breakdowns, it saves money on emergency repairs and unexpected service stops. Plus, nobody wants to deal with train delays caused by something that could have been fixed weeks earlier if only someone had looked at those vibration charts properly.

Retrofitting Older Systems with Modern Clips

Many older railway systems around the world are getting upgraded with modern fasteners meant for high-speed operations these days. What happens during this retrofitting? Basically, engineers fit new components into the old tracks which makes them safer and lets trains run faster. Take a look at Germany and Japan where they've done this kind of work on their aging rail lines. They installed special clips that can handle the stress from superfast trains zipping along at incredible speeds. Of course there are some downsides too. The price tag isn't small, plus maintaining these newer fasteners takes different techniques than before. But when we think about it long term, those extra costs get offset by trains going faster between stops and fewer accidents happening because of better track stability. For cities wanting to keep their railways competitive without building completely new lines, retrofitting offers pretty good value for money spent.

Environmental and Material Optimization

Stainless Steel vs. Composite Material Tradeoffs

Looking at stainless steel against composite materials for railway fasteners shows what works best where. Stainless steel has always been known for its strength and ability to resist corrosion, so it stands up well in tough environments. But there's a catch: it weighs a lot more than alternatives, which matters when trains need to go fast. On the flip side, composites are lighter stuff, helping trains save fuel while putting less strain on tracks over time. Real world testing on high speed lines shows composites cut down maintenance expenses and let trains run quicker without breaking down as much. Meanwhile stainless steel keeps things running reliably for decades if that's what operators want. Take Japan's Shinkansen network and Germany's ICE trains for instance they actually mix both materials depending on local weather patterns and how heavily trafficked certain sections get. Choosing between them comes down to what exactly the railway company wants out of their infrastructure investment.

Protective Coatings for Moisture Resistance

Protective coatings really matter when it comes to making railway fasteners last longer and work better, mainly because they help resist moisture damage. Coatings like zinc and epoxy do the job of protecting metal parts from rusting, something that happens all too often across different weather conditions. Research backs this up showing these coatings stop metal from breaking down over time, which keeps trains running safely and reliably. Take Scandinavia for instance where rail companies applied special coatings to their tracks and saw maintenance needs drop around 30%. New stuff coming out now includes things called nanocomposite coatings that stick better and wear slower than traditional options. While still expensive, these advanced materials might eventually become standard equipment on rails facing extreme weather conditions. For train operators looking to cut down expenses while keeping services dependable, staying informed about coating technology developments makes good business sense.

Thermal Expansion Compensation Methods

When dealing with how fastener materials react to heat and cold, keeping tracks intact during wild temperature swings becomes really important. Materials just don't all behave the same way when temperatures change, so this puts extra strain on railway fasteners and might cause them to shift out of place or even break down over time. Rail companies tackle these problems through clever design solutions. Some use special slip bolts that allow limited movement while others install expansion joints designed specifically to handle those material shifts without losing grip. The railway community has seen good results from these approaches, especially in places with drastic climate differences. Take the Trans Siberian line for instance they've implemented thermal adaptation systems along certain sections which have kept their rails aligned despite freezing winters and scorching summers. With smart engineering work like this, rail networks stay strong and functional no matter what kind of weather comes their way.

Global Best Practices in Fastener Maintenance

Spain's High-Speed Rail Network Innovations

Spain is really stepping up its game when it comes to high speed rail technology, especially around those pesky fastener problems that plague many rail systems. The country has rolled out some pretty impressive tech upgrades across its tracks that make trains run smoother and safer too. What's interesting is how these improvements actually cut down on all those annoying maintenance shutdowns that disrupt schedules so much. Working hand in hand with various tech firms and universities, Spanish engineers developed smart monitoring systems that catch small problems before they turn into big headaches. This means mechanics can fix things before fasteners start failing unexpectedly. As a result, Spanish trains are now running more reliably than ever before. Other nations are taking notice and watching closely to see if they can replicate this success story in their own rail networks.

Japan's Precision Maintenance Regimens

The Japanese approach to rail maintenance is basically what keeps their bullet trains running so smoothly for decades without major issues. They check those tiny fasteners holding everything together with such regularity that breakdowns just don't happen much at all. Looking at actual numbers from JR East alone shows something remarkable: less than one minute of unplanned stoppage per train per year! This kind of track record puts Japanese railways way ahead of safety records elsewhere around the world. What makes this possible? Well, it goes back to how deeply embedded precision work habits are in Japanese culture itself. Train engineers follow routines passed down through generations, often checking components multiple times during routine inspections. For other nations trying to improve their own rail networks, there's plenty to learn from watching how Japan treats maintenance not as a cost center but as an investment in long term reliability.

Lessons from China's Rapid Rail Expansion

The explosive growth of China's railway system teaches valuable lessons about maintaining fasteners in massive infrastructure projects. Home to the globe's biggest high speed rail network, Chinese engineers have developed sophisticated maintenance methods to handle all this expansion. They rely heavily on predictive tech that spots problems before they happen, which keeps trains running safely even as new tracks get laid down constantly. Looking at how China manages its ever growing network shows why good maintenance systems are so crucial when trying to grow big without sacrificing safety or dependability. What works in China could actually work elsewhere too, especially countries starting their own ambitious rail expansions right now.

FAQ

What are the critical components of rail fastening systems?

Rail fastening systems include sleepers, clips, and bolts, all designed to withstand high-speed train forces. Sleepers provide stability, clips hold rails securely, and bolts maintain structural integrity.

Why is fastener integrity crucial for rail safety?

Fastener integrity ensures overall rail safety by preventing derailments caused by loose bolts or inadequate clips, which can lead to component detachment during operation.

How do environmental factors affect railway fasteners?

Environmental factors like moisture and salinity contribute to corrosion. Coastal areas and extreme environments require corrosion-resistant materials and coatings for fasteners.

What measures can be taken to prevent fastener loosening due to dynamic forces?

Using wedge-locking washers, such as Nord-Lock, can resist loosening under dynamic loads, ensuring stronger connections and maintaining rail safety.