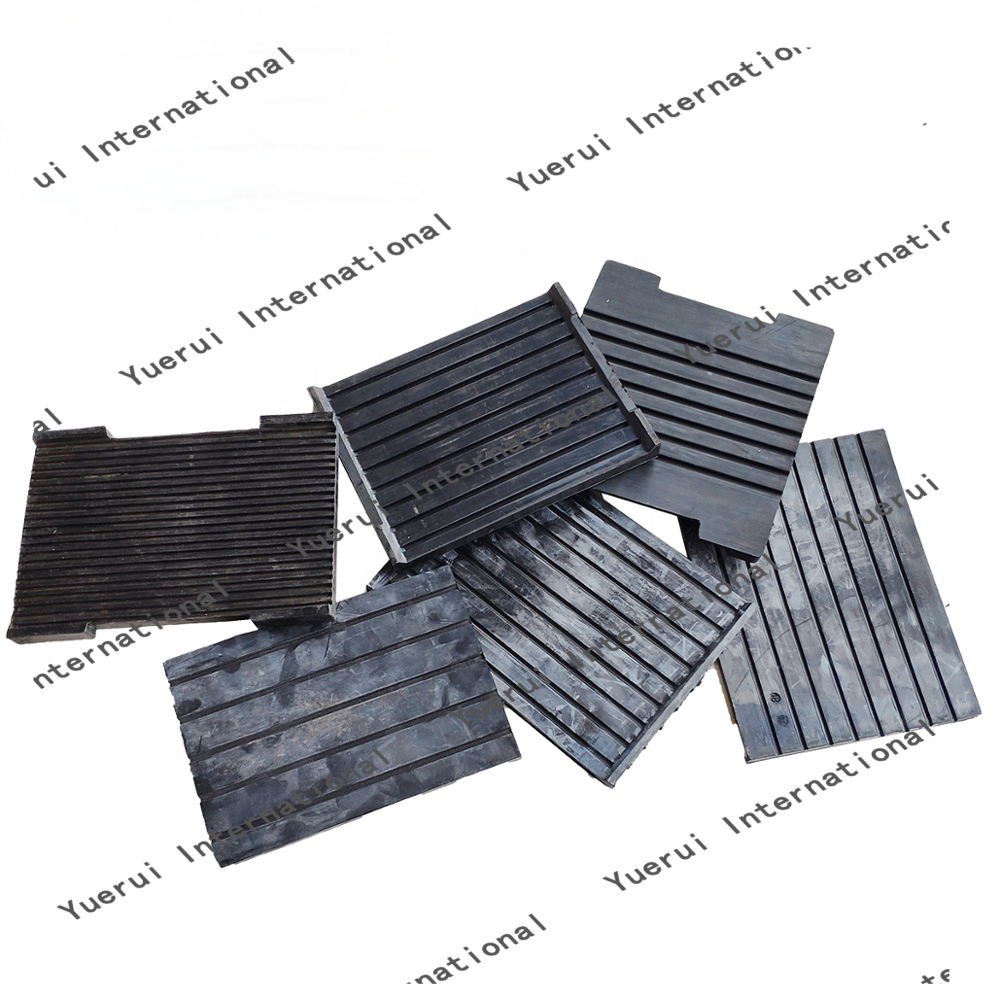

The Versatile Role of Rubber Pads in Modern Industry

Rubber pads have become indispensable components across numerous industries due to their unique combination of flexibility, durability, and vibration-dampening properties. These resilient elements serve critical functions in both automotive and manufacturing environments, where they provide solutions for noise reduction, shock absorption, and equipment protection. The automotive sector relies heavily on rubber pads for everything from engine mounting to interior comfort, while manufacturing facilities utilize them to safeguard sensitive machinery and improve workplace safety. Modern rubber pad formulations offer tailored characteristics to meet specific application requirements, with variations in hardness, chemical resistance, and temperature tolerance. As industries continue pushing for higher efficiency and longer equipment lifecycles, the strategic use of rubber pads has emerged as a simple yet effective method for achieving these goals. Their ability to isolate vibrations, cushion impacts, and reduce friction makes them valuable across countless operational scenarios.

Automotive Applications of Rubber Pads

Vibration Isolation in Vehicle Systems

Rubber pads play a crucial role in managing vibrations throughout automotive designs, significantly improving ride quality and component longevity. Engine mounts incorporating specialized rubber pads absorb the intense vibrations produced by internal combustion, preventing their transmission to the vehicle frame. Transmission systems benefit from rubber pad isolators that dampen gearshift vibrations and reduce cabin noise. Exhaust system hangers frequently utilize rubber pads to suspend components while allowing for thermal expansion and absorbing road shock. Even modern electric vehicles employ rubber pads in battery mounting systems to protect sensitive cells from road vibration damage. The suspension components in virtually all vehicles incorporate rubber pads in bushings and isolators to smooth out road imperfections. Advanced rubber pad formulations in these applications maintain their damping characteristics across extreme temperature ranges from arctic cold to desert heat. Automotive engineers continue developing new rubber pad applications to address NVH (noise, vibration, and harshness) challenges in next-generation vehicle designs.

Interior Comfort and Safety Features

Within vehicle cabins, rubber pads contribute significantly to passenger comfort and safety in often overlooked ways. Dashboard components mount on rubber pads to prevent rattles and absorb minor impacts during normal driving. Door seals and window channels incorporate rubber pad elements to reduce wind noise and ensure smooth operation of moving glass. Center console and storage compartment liners often use soft rubber pads to quieten contents during vehicle motion. Pedal assemblies frequently feature rubber pad covers that improve grip and reduce driver fatigue during extended operation. Child seat anchors commonly include rubber pad interfaces to prevent metal-on-metal contact and reduce installation noise. Even trunk and cargo area liners benefit from rubber pad underlayments that protect surfaces and dampen shifting loads. The automotive industry continues finding innovative ways to incorporate rubber pads into interior designs that enhance both luxury and practicality for vehicle occupants.

Manufacturing Sector Applications

Machinery Vibration Control and Isolation

Industrial facilities rely on rubber pads to protect expensive machinery from vibration-related damage and maintain precise operational tolerances. Heavy equipment such as presses, stamping machines, and CNC equipment often mount on large rubber pads that isolate floor vibrations. Pump and compressor installations frequently incorporate rubber pad bases to prevent vibration transmission through piping systems. Manufacturing conveyor systems use rubber pads at support points to reduce noise and allow for slight misalignments. Precision measurement equipment benefits from rubber pad isolation platforms that eliminate environmental vibrations affecting accuracy. Power generation equipment installations typically specify high-density rubber pads to handle extreme loads while providing necessary vibration damping. The strategic placement of rubber pads in manufacturing environments not only protects equipment but also reduces workplace noise levels, contributing to better employee working conditions. Facilities engineers continue to discover new applications for rubber pads as manufacturing processes become more sophisticated and vibration-sensitive.

Workstation Ergonomics and Safety

Rubber pads contribute significantly to creating safer and more ergonomic manufacturing environments for workers. Anti-fatigue mats made from specialized rubber pads reduce leg and back strain for employees standing for long shifts. Machinery control stations often feature rubber pad flooring to insulate operators from equipment vibrations. Workbenches commonly incorporate rubber pad surfaces to prevent tool slippage and dampen impact noise during assembly operations. Material handling equipment like forklifts uses rubber pad components in seats and armrests to improve operator comfort. Safety barriers and guardrails frequently mount on rubber pad bases that absorb impact energy without damaging floor surfaces. Even storage racks and shelving systems benefit from rubber pad liners that prevent material damage and reduce noise during loading. The versatility of rubber pad materials allows manufacturers to create customized solutions for virtually any workstation ergonomics challenge they encounter.

Specialized Industrial Applications

Material Handling and Conveyor Systems

Rubber pads find extensive use in material handling systems where they solve multiple operational challenges simultaneously. Conveyor rollers often incorporate rubber pad covers that improve grip on conveyed items while reducing noise levels. Sorting system impact zones frequently line with thick rubber pads to cushion falls and protect both products and equipment. Pallet rack systems use rubber pad corner protectors that prevent damage during forklift operations. Automated guided vehicles (AGVs) employ rubber pad bumpers that absorb collision energy without damaging infrastructure. Bulk material handling chutes often line with wear-resistant rubber pads that extend service life while reducing noise from falling materials. The food processing industry particularly values rubber pad components that meet sanitary standards while providing necessary cushioning and vibration control. These diverse applications demonstrate how rubber pads contribute to both efficiency and equipment preservation in material handling operations.

Structural Isolation and Seismic Protection

In industrial construction, rubber pads serve critical functions in structural isolation and seismic protection systems. Bridge bearings frequently incorporate layered rubber pads that allow for thermal expansion while dampening traffic vibrations. Building foundation isolators use massive rubber pads to absorb earthquake energy and protect structures during seismic events. Pipe supports in industrial plants employ rubber pads that allow for thermal movement while reducing vibration transmission. Equipment platforms in vibration-sensitive facilities like laboratories often float on rubber pad isolation systems. Even rooftop HVAC installations commonly use rubber pad mounts that prevent noise transmission into occupied spaces below. The ability of modern rubber pad compounds to maintain their properties under constant load for decades makes them ideal for these long-term structural applications. Engineers continue to develop new rubber pad formulations that push the boundaries of load capacity and durability for these demanding uses.

Advanced Material Innovations

High-Performance Rubber Pad Formulations

Recent advancements in rubber pad materials have expanded their applications into more demanding industrial environments. High-temperature rubber pads now withstand continuous operation in foundries and engine rooms where temperatures exceed 300°F. Chemical-resistant formulations allow rubber pads to perform in harsh environments with exposure to oils, solvents, and aggressive cleaning agents. Conductive rubber pads find use in electrostatic discharge (ESD) sensitive areas like electronics manufacturing. Food-grade rubber pad materials meet stringent FDA requirements for direct contact with edible products. Flame-retardant rubber pads provide critical safety margins in electrical equipment and high-heat industrial processes. Even extreme cold applications benefit from specialized rubber pad compounds that remain flexible at arctic temperatures. These material innovations ensure rubber pads can meet the evolving needs of both automotive and manufacturing sectors as they adopt new technologies and processes.

Custom Engineered Rubber Pad Solutions

Manufacturers increasingly turn to customized rubber pad solutions to address specific application challenges. Molded rubber pads with complex geometries provide exact fit solutions for unique equipment mounting requirements. Multi-layer rubber pad designs combine different hardness levels to achieve precise vibration isolation characteristics. Perforated rubber pad patterns enhance drainage in wet environments while maintaining cushioning properties. Colored rubber pads help with visual organization and safety coding in industrial facilities. Embedded reinforcement materials like fabric or metal inserts create rubber pads with enhanced load-bearing capabilities. Even surface textures can be specially engineered to provide optimal friction characteristics for specific applications. This trend toward customization allows engineers to specify rubber pad solutions that precisely match their performance requirements rather than adapting designs to accommodate off-the-shelf products.

FAQ

How long do rubber pads typically last in industrial applications?

The lifespan of rubber pads varies significantly based on material composition, environmental conditions, and load factors. High-quality rubber pads in moderate service conditions often last 5-10 years, while specialized formulations in demanding applications may require replacement every 2-3 years. Regular inspections should check for hardening, cracking, or compression set that indicates replacement is needed.

Can rubber pads be recycled after use?

Many rubber pad materials can be recycled, though the feasibility depends on the specific compound and contamination level during use. Some manufacturers offer take-back programs for used rubber pads, while specialized recyclers can process them into rubber mulch or other products. Thermoplastic rubber pads offer better recyclability than thermoset varieties in many cases.

How do temperature extremes affect rubber pad performance?

Rubber pads become harder and less flexible in cold temperatures while potentially softening or degrading in extreme heat. Specialized formulations address these limitations—low-temperature rubber pads maintain flexibility below freezing, while high-temperature versions resist degradation in hot environments. Always select rubber pads rated for your application's temperature range.

Are there alternatives to rubber pads for vibration isolation?

While alternatives like springs, cork, or foam materials exist, rubber pads often provide the best balance of performance, cost, and durability for most applications. Newer materials like silicone or polyurethane-based pads offer alternatives where standard rubber has limitations, though often at higher cost. The choice depends on specific performance requirements and environmental conditions.