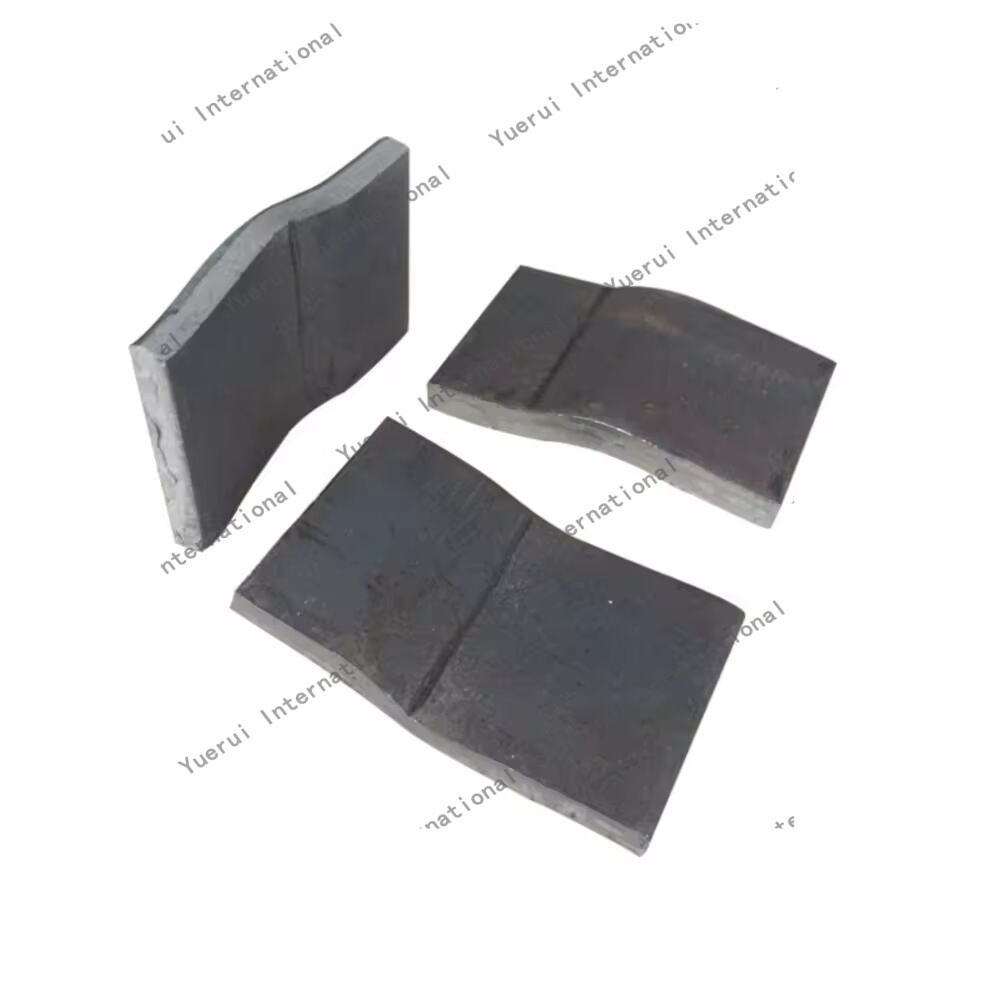

bloc méadadh cruach

Blocanna stáil, a dtugtar orthu fosta blocanna méidithe nó gage gauges, iad uirlisí mírimeádaithe atá ag tabhairt bunús don rialú chéim-mhéadrachta i bhfeabhsaíocht agus i gcásadh. Déantar na blocanna seo, a bhfuil siad in ann dul chun dímaíochtaí fíor mhóra, mar phríomhriailithe ar leith do mheastacháin faighte i ngníomhachas. Déantar iad ón allaimh stáil ardleibhéal, agus cuireadh i gcás go mbeidh stabhlacht diméad acu le cúrsaí fada, le leibhéal mírimeádaithe idir ±0.00001 go ±0.000001 colún. Tá dhá fhaosóg coibhneasta acu glacadh agus lámháilte chun comhthéacs fíor agus coibhneasta a bhaint amach, énár is féidir leo brúchán a chur le chéile trí threorach moleacúlach. Cuirimid an t-eagair seo speisialta i bhfeidhm chun blocanna éagsúla a chumasc chun dímaíochtaí spéisíocha a bhaint amach. Is gnásacha iad na blocanna stáil chun comhpháirteachtaí a chalibráil, chun tuilleadh árthréime a shocrú ar chomhaid meastacháin, agus chun comhionannacht na ndíluithe feabhsaithe a dearbhadh. Le linn an tsaincheartaithe, déantar próiseas rialta ciallmhar ar na blocanna seo agus deifirtear iad go háirithe le certifikéad calibrála chun trasaábhlacht chuig scileanna náisiúnta a chur i bhfeidhm.