Subway Clips is a key component in the subway rail fastening system.

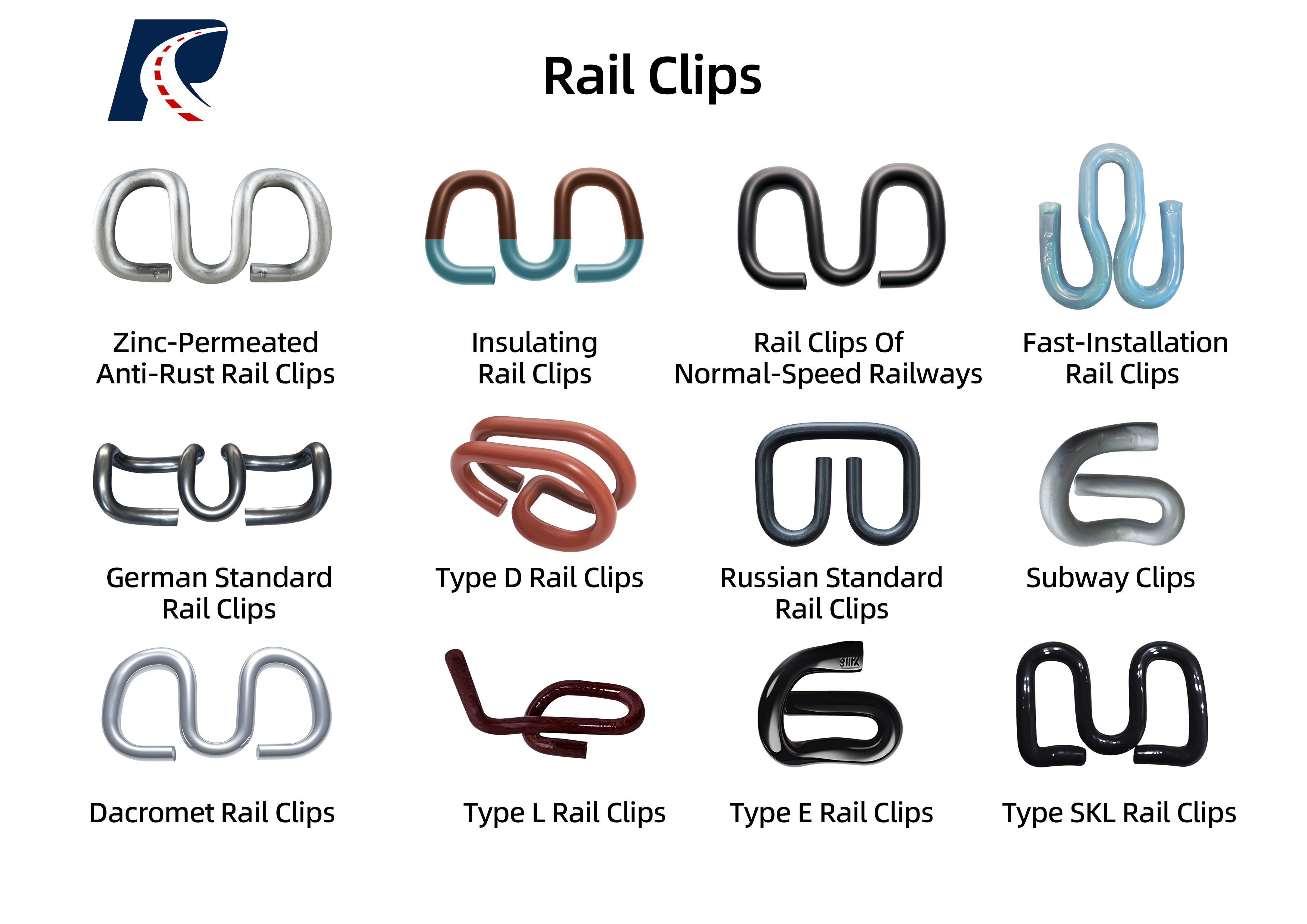

We utilize premium raw materials in the production of rail clips to ensure high tensile strength and corrosion resistance. Moreover, our products can be customized to meet clients' specific requirements.

Function and Importance of Clip

Rails are secured to the ballast or sleepers via elastic fastenings. The primary clamping component of these fastenings is the rail clip. Through its bending and torsional deformation, the clip generates clamping force on the track. This ensures a reliable and long-term connection between rails, maintains track integrity as much as possible, prevents longitudinal and lateral movement of rails relative to sleepers, and safeguards gauge stability—thereby guaranteeing the safe operation of rolling stock. Additionally, since the contact between train wheels and rails is rigid, vibrations inevitably occur. The special elastic structure of the fishplate also enables it to absorb the impact energy generated when vehicles pass over, achieving a shock-absorbing effect. Spring clips operate under repeated alternating stresses, enduring bending, torsion, fatigue, and corrosion. When vehicles pass over them, they also withstand extremely high instantaneous impact loads. Consequently, the performance requirements for spring clips are exceptionally stringent.

Railway Track Components: Professional Supply from Yue Rui

As a seasoned manufacturer of railway track components with over 30 years' experience, All of our items are strictly according to the testing standard. Our competitive pricing and in - house production capabilities enable us to offer superior value compared to your current supplier. We can also assist in developing advanced technical products tailored to your needs. A multi-channel supply chain can make your company more competitive in the market. What's more, Yue Rui boasts a highly efficient and professional team to serve you, which will help save your time and technical costs. The Yue Rui team is highly specialized and has a strong sense of responsibility, working to reduce risks and ensure your satisfaction.

| Type | Diameter(mm) | Weight(kg) | Material |

| Type A | Ø13 | 0.48kg | 60Si2Mn |

| Type B | Ø13 | 0.45kg | 60Si2Mn |

| W1 | Ø14 | 0.7kg | 60Si2Mn |

| Type III | Ø20 | 0.825kg | 60Si2Mn |

| Type I | Ø18 | 0.80kg | 60Si2MnA |

| E1609 | Ø16 | 0.45kg | 60Si3MnA |

| E1809 | Ø20 | 0.61kg | 60Si2MnA |

| E1813 | Ø18 | 0.62kg | 60Si2MnA |

| E2001 | Ø20 | 0.80kg | 60Si2MnA |

| E2007 | Ø20 | 0.80kg | 60Si2MnA |

| E2009 | Ø20 | 0.80kg | 60Si2MnA |

| E2039 | Ø20 | 0.80kg | 60Si2MnA |

| E2055 | Ø20 | 0.80kg | 60Si2MnA |

| E2056 | Ø20 | 0.80kg | 60Si2MnA |

| E2063 | Ø20 | 0.80kg | 60Si2MnA |

| SKL 1 | Ø13 | 0.48kg | 60Si2Mn |

| SKL 3 | Ø13 | 0.48kg | 60Si2CrA |

| SKL 12 | Ø13 | 0.53kg | 38Si7 |

| SKL 14 | Ø13 | 0.53kg | 60Si2MnA |

Quality Assurance for Clip Production

Yue Rui's Rail Clips production adheres to a quality-driven business philosophy, placing significant emphasis on quality control and management. Our clip manufacturing is fully controlled in accordance with the ISO 9001:2015 quality system, and we hold a Railway Product Manufacturing License. We possess comprehensive testing equipment to ensure all clip products meet customer requirements. All processes adhere to ISO quality management system requirements. From supplier quality control to finished products, we operate according to standardized procedures. We maintain a rigorous quality control system for suppliers:

6 Reasons for Choosing Yue Rui

Yue Rui has the largest production base in China for manufacturing various types of Rail Clips.

1. Our products feature meticulous design, along with high tensile strength and corrosion resistance. We use high-quality spring steel, strictly adhere to quality and technical requirements during production, and offer optimized prices.

2. We provide customization services based on drawings or samples to ensure customer satisfaction.

3. For raw material inspection and testing, we require suppliers to provide production batch numbers, chemical composition, mechanical properties, and other testing metrics.

4. Our quality control inspectors conduct sampling and batch testing during the inspection process, while also requiring material certificates for raw materials.

5. Based on specific product requirements, we conduct corresponding physical and chemical tests and inspections. Materials failing to meet our standards are rejected; only compliant materials are accepted.

6. For semi-finished products and external manufacturers, we regularly organize quality control coordination meetings and provide technical support and guidance. This ensures only qualified products are delivered to our customers prior to shipment.