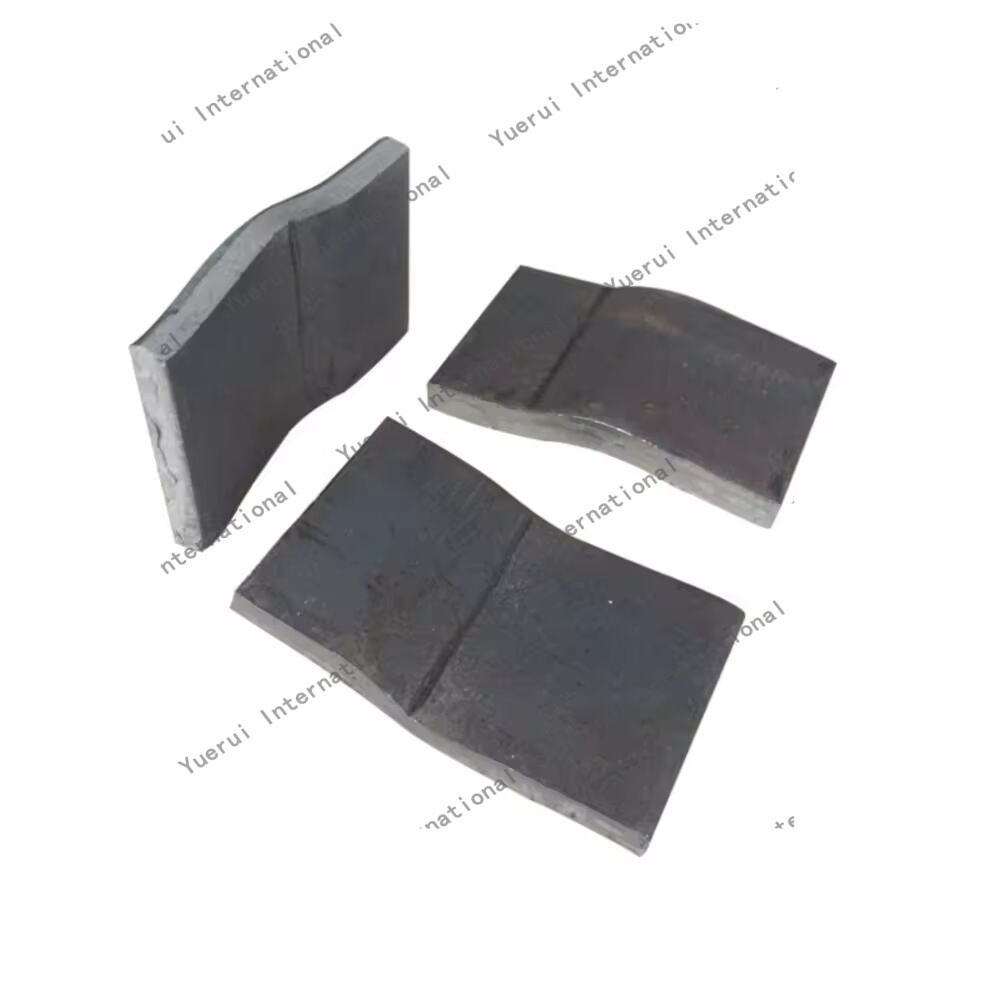

1 gage block

The 1 gage block represents a fundamental tool in precision measurement and calibration processes, serving as a crucial reference standard in dimensional metrology. These blocks are manufactured to extremely tight tolerances, typically offering accuracy within millionths of an inch. Crafted from specialized steel alloys or ceramic materials, 1 gage blocks are designed to maintain dimensional stability over extended periods. They feature perfectly parallel surfaces that have been lapped and polished to achieve exceptional flatness and surface finish. The 1 designation typically refers to a specific size or grade classification, indicating the highest level of precision available. These blocks are essential in various industrial applications, from toolmaking and machining to quality control and inspection processes. They serve as master references for calibrating measuring instruments, setting up precision equipment, and verifying the accuracy of other measurement devices. The blocks undergo rigorous certification processes to ensure traceability to national measurement standards, making them invaluable in industries where precise measurements are critical, such as aerospace, automotive manufacturing, and scientific research.