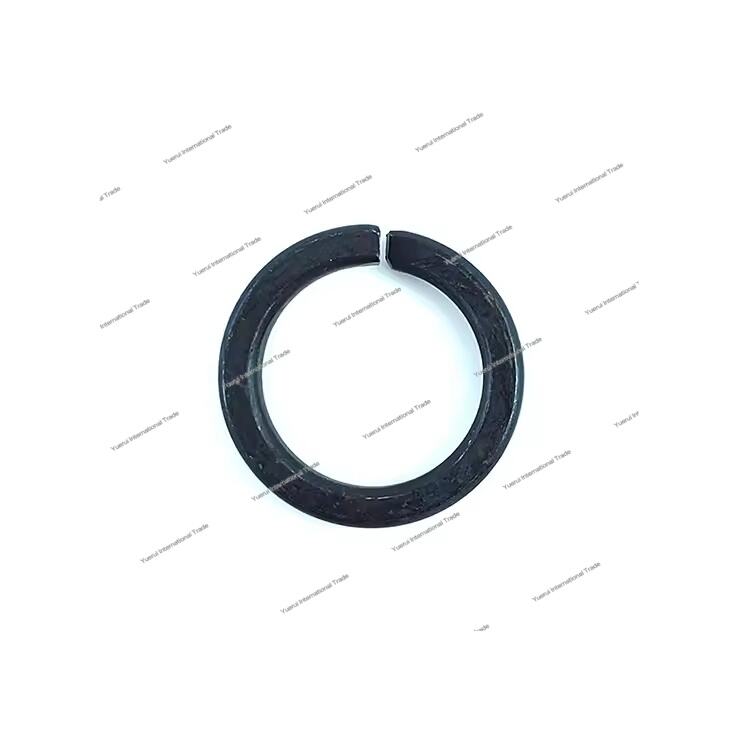

flat washers for railway

Flat washers for railway systems are essential components designed to distribute load and prevent damage in rail infrastructure installations. These precision-engineered components play a crucial role in maintaining the integrity of rail fastening systems by providing an even pressure distribution between bolted surfaces. Manufactured to meet stringent railway industry standards, these washers feature specific material compositions that ensure durability under extreme conditions, including high vibration environments and varying weather conditions. The washers are typically produced from high-grade steel with protective coatings to prevent corrosion and extend service life. Their precise dimensional tolerances contribute to proper bolt tension maintenance and help prevent loosening due to dynamic loads. Railway flat washers are specifically designed to withstand the unique challenges of rail applications, including constant vibration, thermal expansion and contraction, and exposure to environmental elements. These components are essential in various railway applications, from track fastening systems to signal equipment mounting and platform construction. The careful engineering behind these washers ensures they maintain their structural integrity while providing consistent performance throughout their service life, making them indispensable in modern railway infrastructure maintenance and construction.