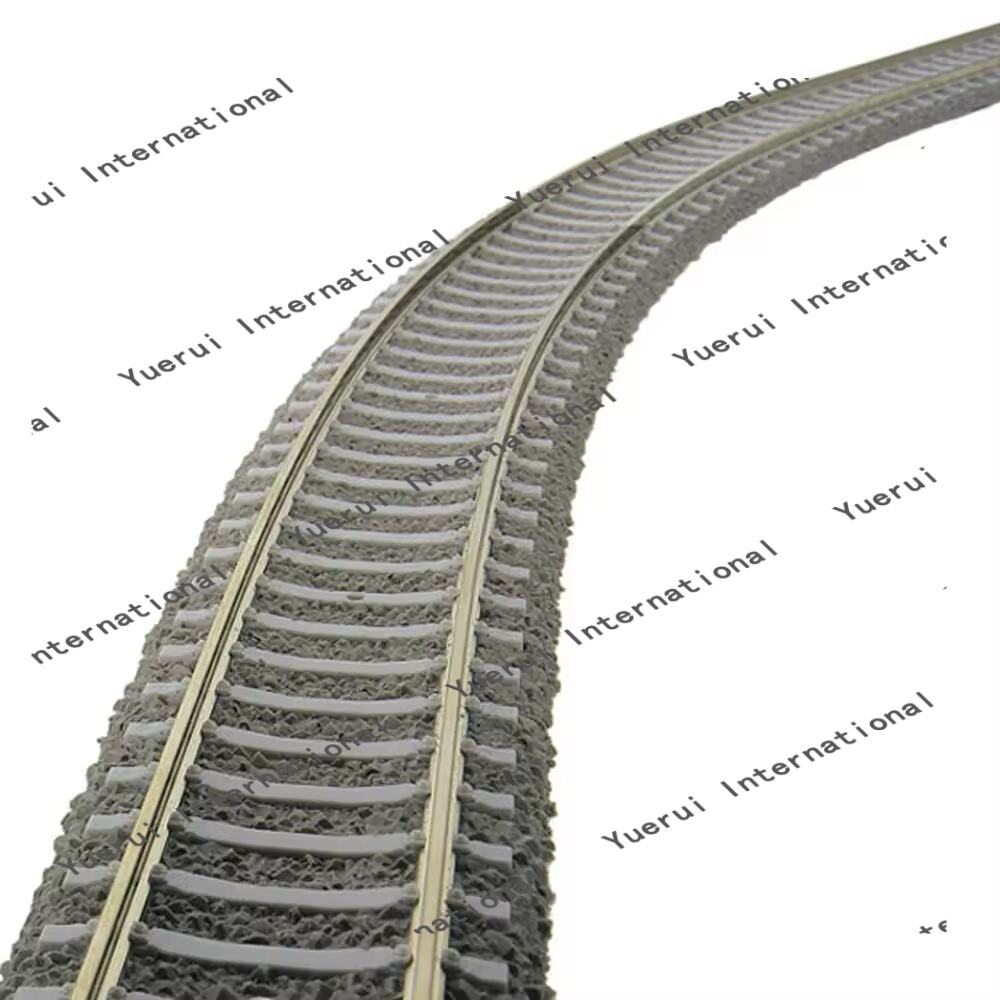

new railroad ties

Modern railroad ties represent a significant advancement in railway infrastructure technology, combining durability, sustainability, and enhanced performance characteristics. These innovative components serve as the crucial foundation for railway tracks, providing essential support and stability for rail operations. Engineered with advanced composite materials, these ties feature enhanced resistance to environmental factors, including moisture, temperature variations, and mechanical stress. The construction incorporates specialized polymers and reinforced concrete, creating a robust structure that maintains dimensional stability under heavy loads. These ties are designed with precision-engineered fastening systems that ensure secure rail attachment while allowing for necessary thermal expansion and contraction. The surface texture and internal structure are optimized to provide superior ballast interaction, reducing maintenance requirements and extending service life. Additionally, these ties feature integrated drainage channels and moisture barriers, preventing water accumulation and reducing degradation risks. The manufacturing process employs sustainable practices, utilizing recycled materials where possible while maintaining strict quality control standards. These components are compatible with existing railway infrastructure, making them suitable for both new installations and replacement projects across various railway applications, from heavy freight corridors to high-speed passenger lines.