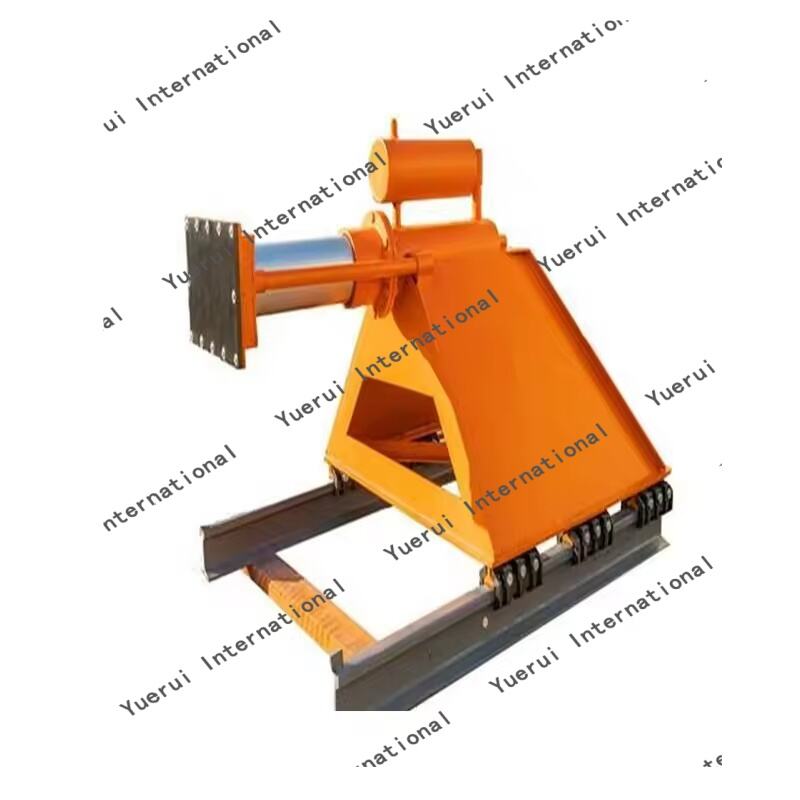

railroad tools and equipment

Railroad tools and equipment represent essential components in modern railway maintenance and construction operations. These specialized implements range from basic hand tools to sophisticated mechanical systems designed specifically for rail work. The toolkit includes track maintenance equipment such as rail wrenches, spike pullers, track jacks, and rail saws, which are crucial for maintaining track integrity. Advanced diagnostic tools featuring ultrasonic testing equipment and rail flaw detectors help identify potential issues before they become critical problems. Track laying equipment, including tie inserters and rail threaders, facilitates efficient installation and replacement of railway components. Modern railroad equipment also incorporates computerized systems for precise alignment and measurement, ensuring optimal track geometry and safety standards. Portable power tools, designed specifically for railroad applications, enable quick repairs and modifications in the field. Safety equipment, such as warning systems and protective gear, forms an integral part of the railroad toolkit. These tools are engineered to withstand heavy-duty use and extreme weather conditions, incorporating durable materials and ergonomic designs for improved operator comfort and efficiency.