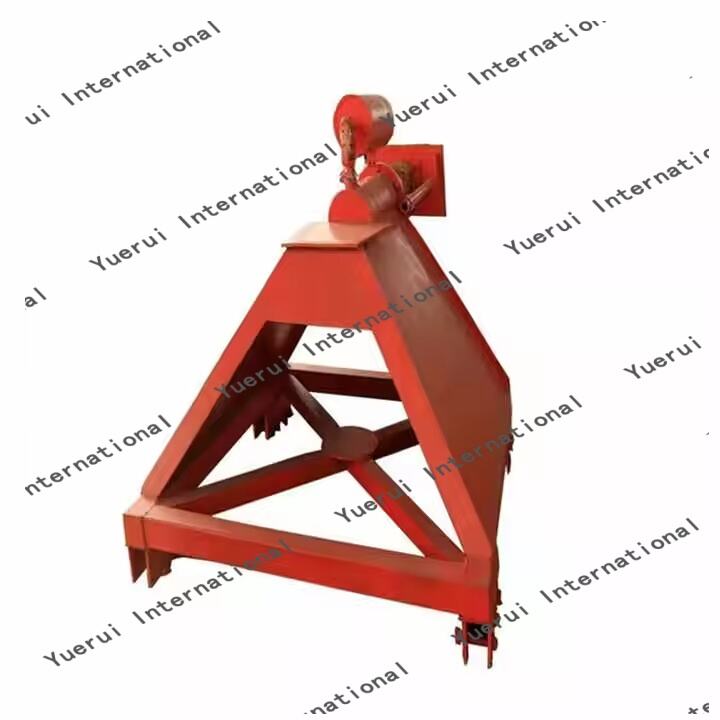

railway track construction equipment

Railway track construction equipment represents a comprehensive suite of specialized machinery designed for the efficient installation, maintenance, and renovation of railway infrastructure. These advanced systems encompass track laying machines, ballast regulators, tamping machines, and rail welding equipment, all working in concert to ensure precise track alignment and stability. The equipment utilizes state-of-the-art technology, including GPS guidance systems and laser-guided positioning, to achieve millimeter-perfect track placement. Modern railway construction equipment features automated systems that can simultaneously handle multiple tasks, such as laying sleepers, positioning rails, and distributing ballast. These machines are capable of operating in various environmental conditions and can accommodate different track gauges and rail specifications. The equipment's versatility extends to both new track construction and rehabilitation projects, offering solutions for both mainline railways and urban transit systems. Safety features are integrated throughout the design, including emergency stop systems and real-time monitoring capabilities that ensure optimal performance while protecting both operators and infrastructure.