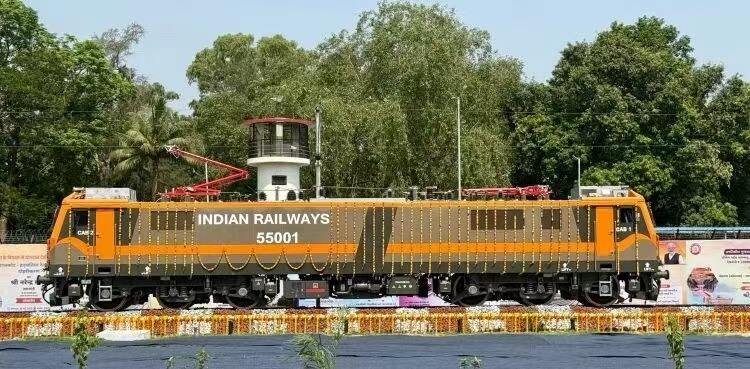

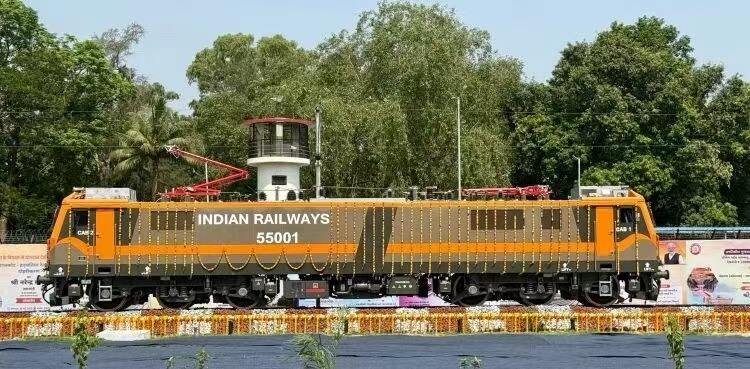

Indian Prime Minister Narendra Modi inaugurated the first batch of new D9-9000 horsepower (6.7MW) electric locomotives at the Indian Railways factory in Dahod, Gujarat.

Siemens previously secured a contract for the design, engineering, manufacturing, and maintenance of 1,200 such 9,000-horsepower electric locomotives. Its factories in Nashik, Aurangabad, and Mumbai are responsible for producing key components of the project, while final assembly, testing, and commissioning are carried out at the Dahod Indian Railways factory. Built in less than two years—a record-breaking feat—the Dahod facility is equipped with cutting-edge amenities, including virtual reality (VR)-based safety training facilities, locomotive simulators, and shunting machines for efficient carriage movement.

Sunil Mathur, Managing Director and CEO of Siemens Limited, stated that Siemens is honored to collaborate with Indian Railways on this project. Together, they have created a world-class factory, with approximately 90% of the technology for the 9,000-horsepower electric locomotives being indigenously manufactured in India. The introduction of these advanced locomotives is crucial for the Indian government to achieve its goal of increasing the railway’s share in freight transport from 27% to around 45%. Each locomotive, with a maximum speed of 120 km/h and a traction capacity of 5,800 tons, is designed for efficient cargo transportation. Siemens will also provide 35-year full lifecycle maintenance for these locomotives, which are equipped with Siemens’ Railigent X platform for predictive maintenance, advanced digital tracking systems, the Kavach safety system, and green propulsion technology, setting a benchmark for modern rail transport.

This project is part of a broader framework that includes the delivery of 1,200 locomotives over the next few years. The new locomotive platform is developed and maintained under a contract awarded to Siemens Mobility, with components produced at multiple sites in India and final assembly at the Dahod factory. Its state-of-the-art facilities provide a strong guarantee for the smooth implementation of the project.