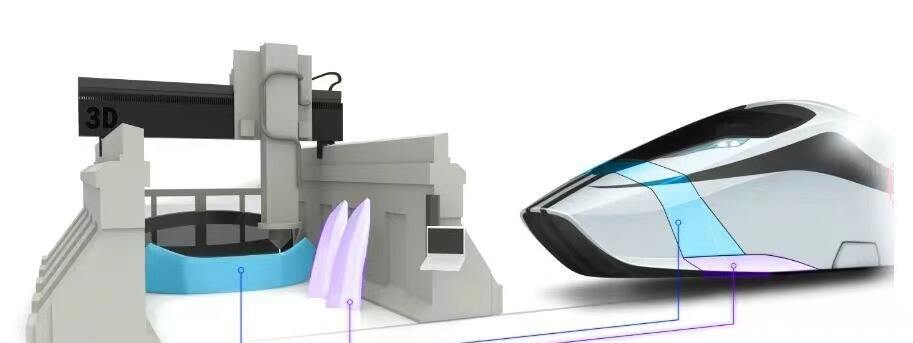

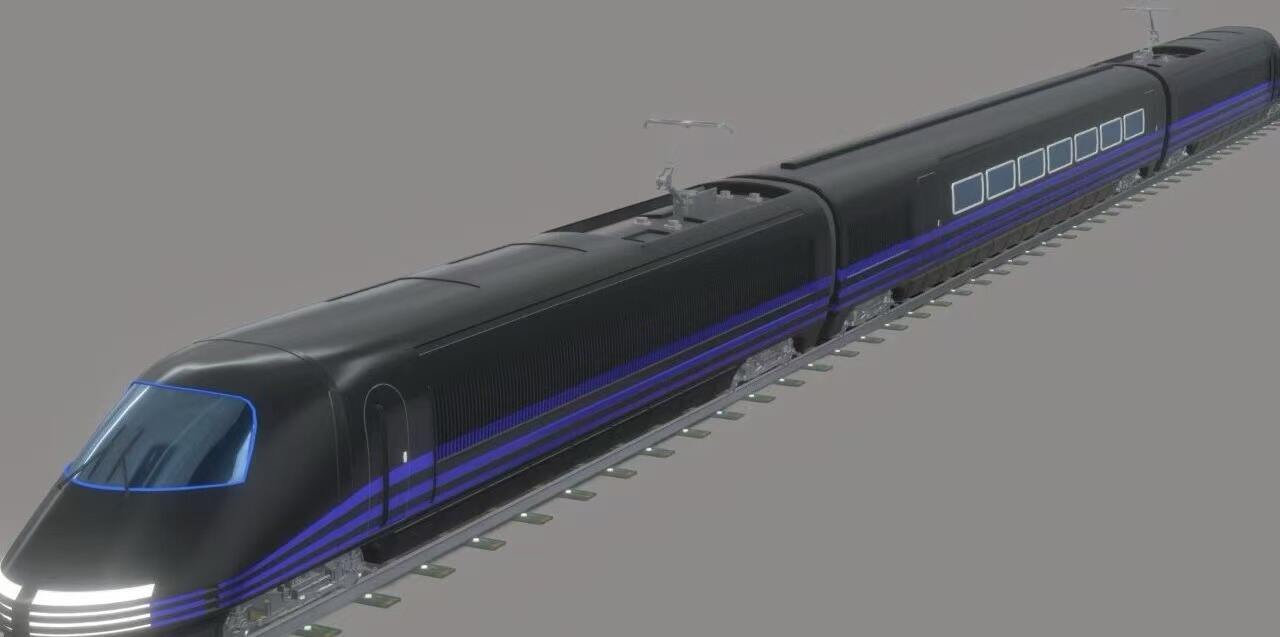

A research consortium in Europe is developing an innovative thermoplastic material technology that combines large-format 3D printing with 3D tape laying processes, opening up a new path for rail vehicle manufacturing. This technology enables direct production of large, complex and flexible components such as front masks and roof structures without the need for molds, making it particularly suitable for small and medium-batch production scenarios.

Notably, the structure of 3D printed continuous fiber-reinforced thermoplastic composites (CFRTPC) exhibits the advantages of clear microfiber distribution paths and multi-scale characteristics in macrostructure. Compared with traditional thermosetting fiber composite processes, this additive thermoplastic process eliminates mold investment. Combined with highly automated production and the application of reusable materials, it can not only reduce manufacturing costs and improve resource utilization efficiency, but also optimize time and material consumption, significantly reducing carbon emissions.