Shift2Rail is Europe's first railway program focusing on research and innovation (R&I) and market-driven solutions by accelerating the integration of new and advanced technologies into innovative railway product solutions.

As carbon fiber composite materials are brittle with significantly lower elongation than commonly used ductile materials such as aluminum alloys, stainless steel, and carbon steel, the collision performance of car bodies made of this material is one of the key research contents of the project. The project conducted collision research on the front structure of composite car bodies, and the preliminary results showed some cracking (uncontrollable deformation) instead of the ductile deformation of metal structures, which has an adverse impact on protecting passenger safety. Later, through reinforcing the composite structure or extending the surrounding metal interface, the collision scenario test was finally passed. The key point of the solution is to transfer the energy previously absorbed by the deformable zone structure of the car body to the non-structural collision energy-absorbing device.

Based on the project research results, a recommendation is put forward for composite car bodies: the main structure of the car body is not allowed to be damaged in collision scenarios. This recommendation is much stricter than the current industry universal standard EN 15227 (the deformation of the passenger survival space length per 5m shall not exceed 50mm or the plastic strain in these areas is 10%; for the car body end, the maximum reduction of 5m length is allowed to be 100mm).

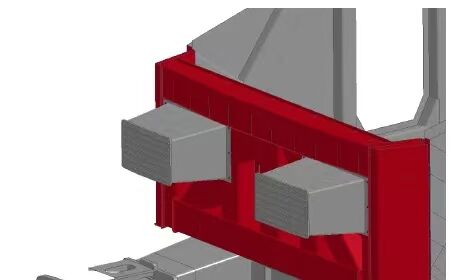

Structure diagram of car body collision energy absorption