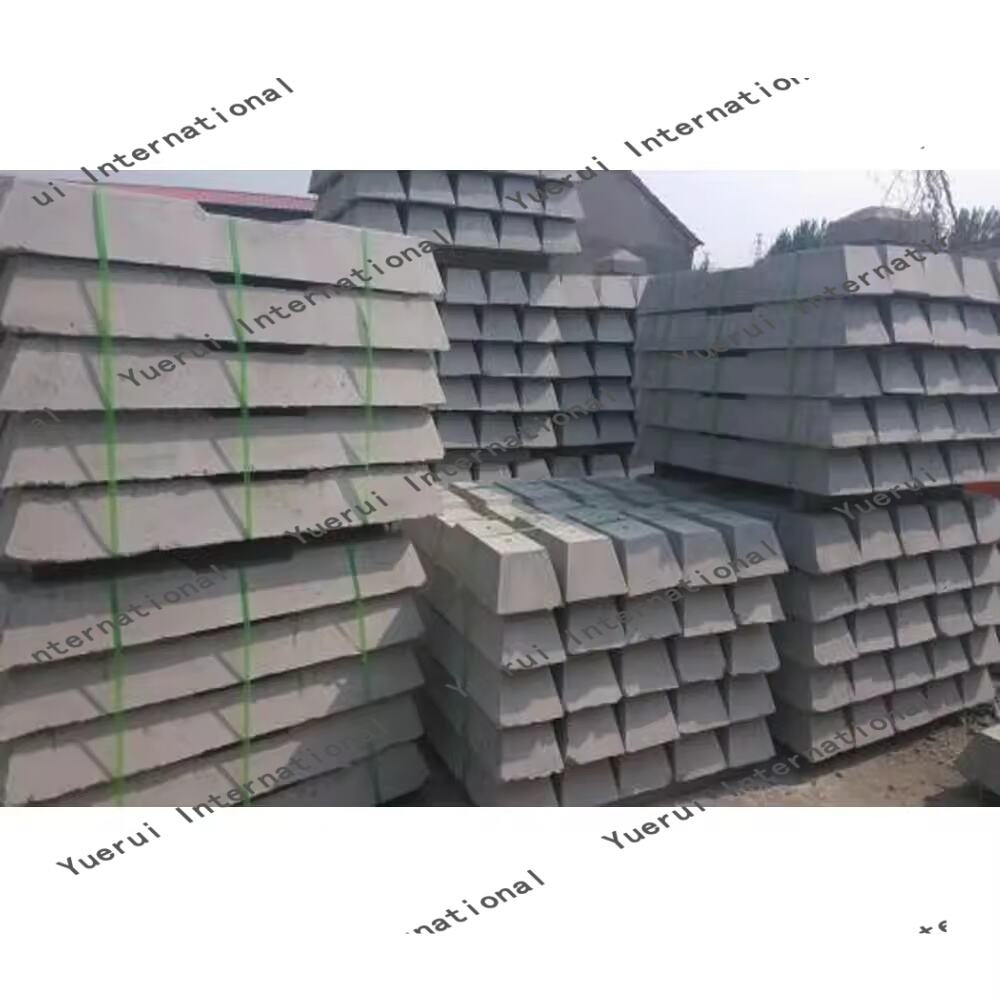

cement railroad ties

Cement railroad ties, also known as concrete sleepers, represent a significant advancement in railway infrastructure technology. These essential components serve as the foundation for modern rail systems, providing crucial support for rails while ensuring optimal load distribution across the track bed. Manufactured through a sophisticated process combining high-strength concrete and pre-stressed steel reinforcement, these ties offer superior structural integrity and longevity compared to traditional wooden alternatives. The ties are designed to withstand extreme weather conditions, heavy axle loads, and high-speed rail traffic while maintaining track geometry and alignment. Their precise dimensional control and engineered surface texture ensure proper rail fastening and track stability. Modern cement railroad ties incorporate advanced features such as elastic rail fastening systems, built-in electrical insulation properties, and specialized designs for various track configurations. They play a vital role in reducing maintenance requirements, extending track life, and enhancing overall railway system performance. The implementation of these ties has become increasingly prevalent in both new construction and track renewal projects worldwide, particularly in high-speed rail corridors and heavy-haul freight lines where performance demands are most stringent.