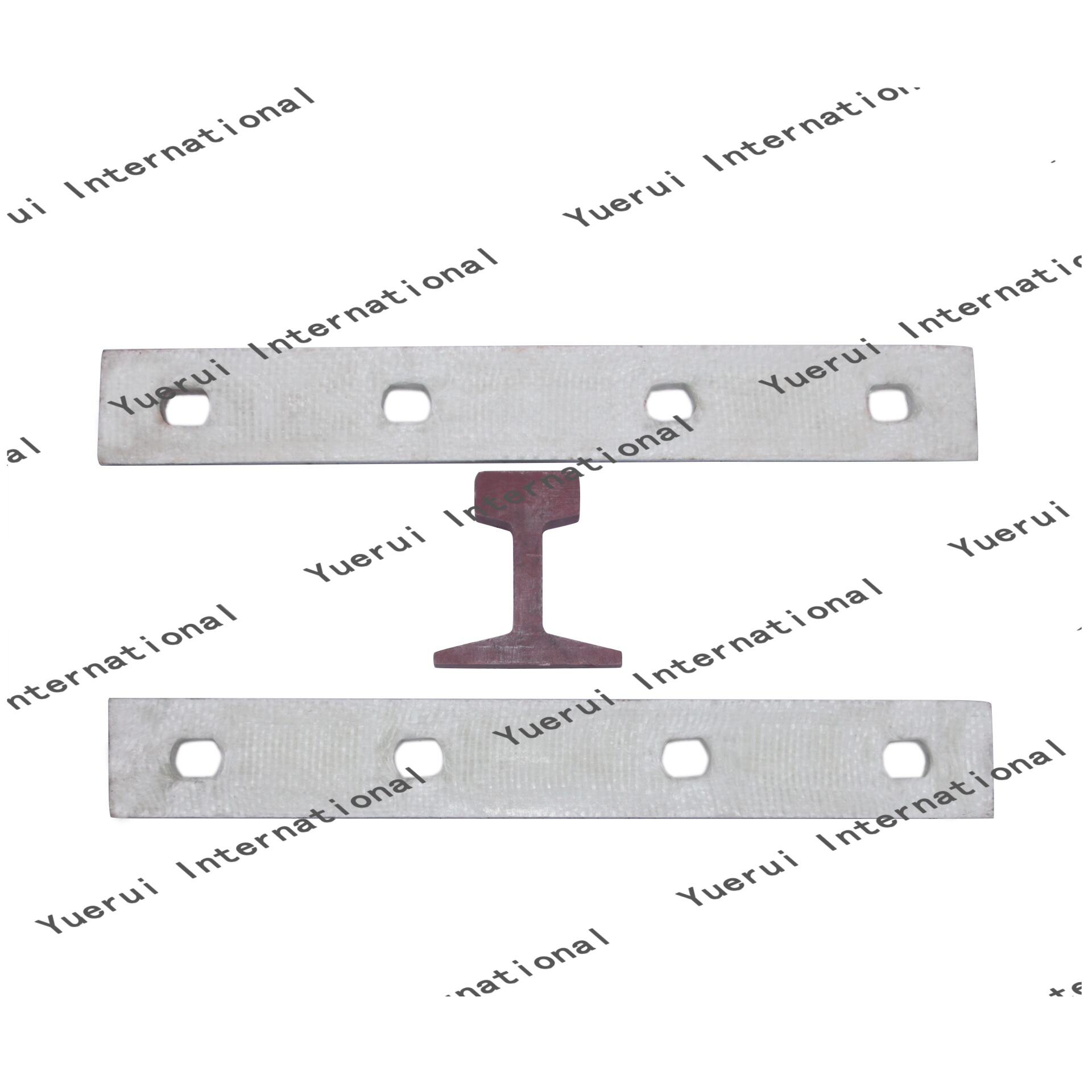

fish plate in railway

A fish plate in railway systems is a crucial connecting component that joins two rail sections together, ensuring continuous and smooth rail operation. This essential piece of railway infrastructure consists of a pair of metal plates that bolt on either side of the rail joints, effectively bridging the gap between rail sections. The fish plate derives its name from the fish-like shape of the plates when viewed from the side. These components are specifically designed to maintain proper track alignment, prevent lateral and vertical movement of rail ends, and distribute the load evenly across the joint. Modern fish plates are manufactured using high-grade steel and undergo rigorous testing to ensure they meet safety and durability standards. They feature precisely drilled holes that align with corresponding holes in the rail ends, allowing for secure bolted connections. The design incorporates specific dimensions and tolerances that account for thermal expansion and contraction of rails, while maintaining structural integrity under varying weather conditions and heavy loads. In contemporary railway systems, fish plates play a vital role in track maintenance and safety, serving as both a mechanical connector and a stress distributor across rail joints.