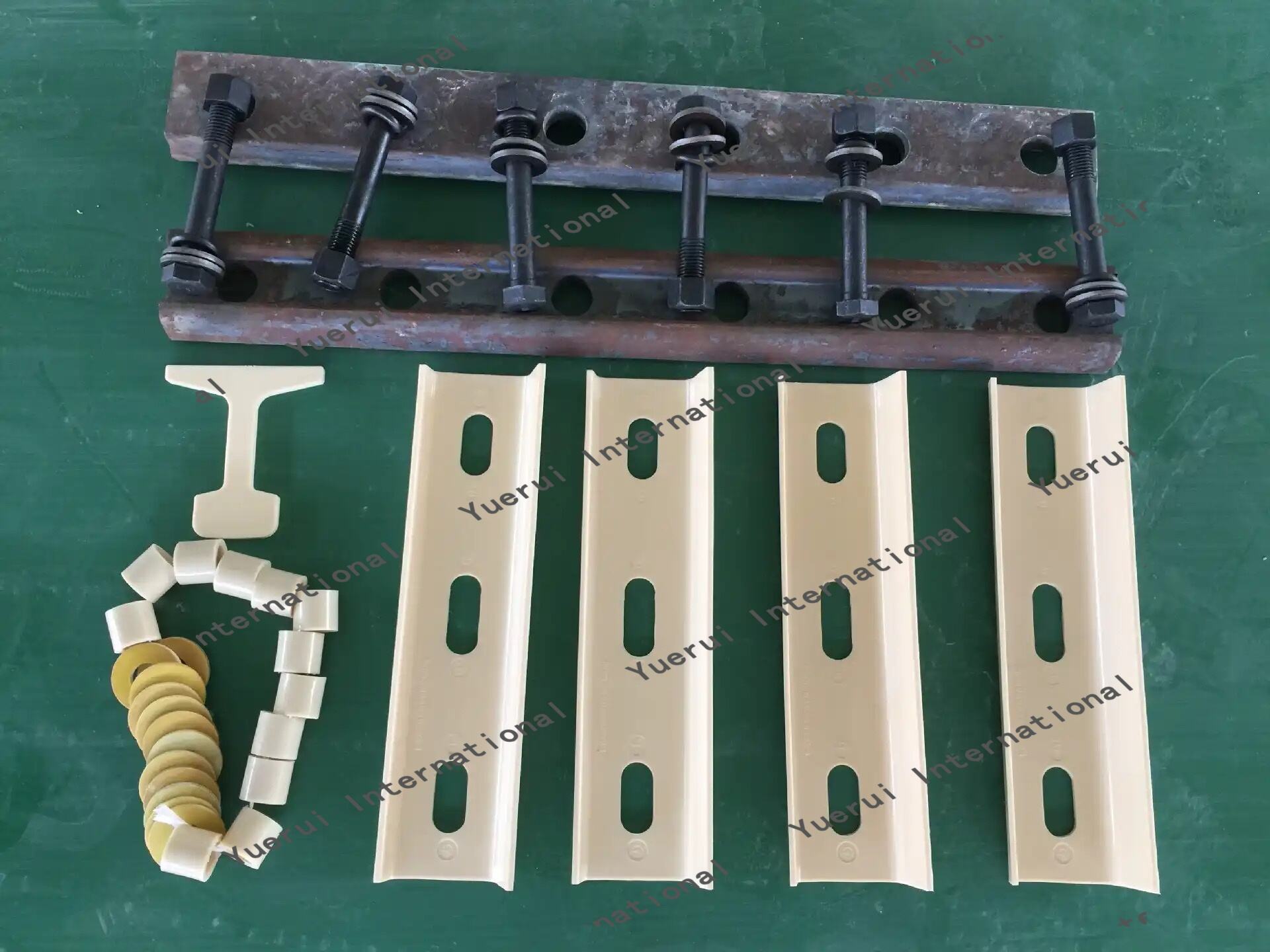

insulation joint

An insulation joint is a critical component in pipeline systems designed to provide electrical isolation between different sections while maintaining mechanical integrity and fluid flow. These specialized fittings integrate multiple features including a non-conductive seal, high-strength insulating material, and protective elements that prevent electrical current from bypassing the intended isolation point. The joint's primary function is to separate cathodic protection systems, prevent stray current corrosion, and maintain the integrity of pipeline monitoring systems. Modern insulation joints incorporate advanced materials such as glass-reinforced epoxy and specialized elastomers that ensure both reliable electrical isolation and exceptional mechanical strength. The design typically includes multiple barriers and fail-safes to guarantee long-term performance even under challenging operating conditions. These joints are extensively used in oil and gas transmission lines, chemical processing facilities, and water distribution networks, where they play a crucial role in corrosion prevention and system protection. The technology behind insulation joints has evolved significantly, now featuring sophisticated monitoring capabilities and enhanced safety features that meet stringent industry standards and regulations.