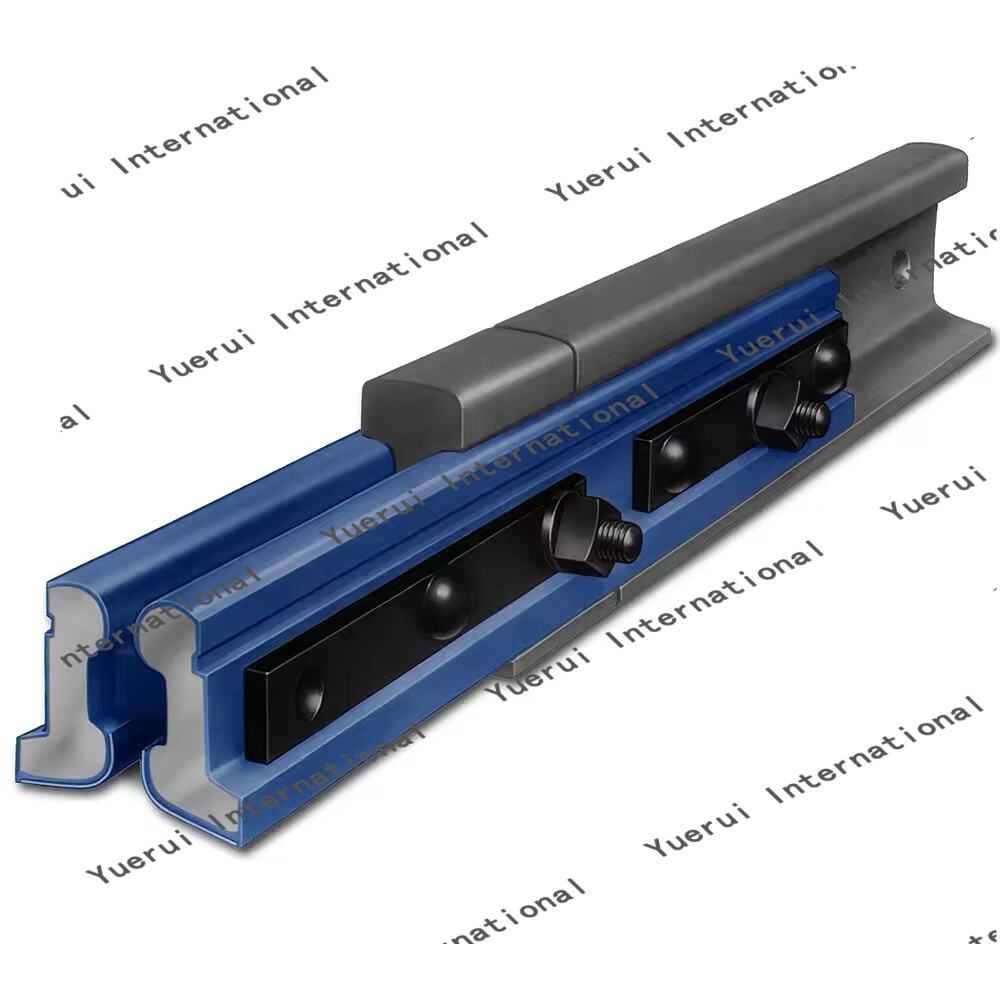

insulation joint for railway

An insulation joint for railway systems serves as a critical component in track infrastructure, designed to electrically separate different rail sections while maintaining structural continuity. This specialized joint creates an electrical barrier between track sections, preventing signal interference and ensuring proper operation of train detection systems. The joint comprises high-strength composite materials sandwiched between metal endposts, featuring specially engineered insulating components that withstand extreme mechanical loads and environmental conditions. The design incorporates advanced bonding technology that ensures durability under heavy rail traffic while maintaining electrical isolation properties. These joints are essential for track circuitry systems, allowing for accurate train position detection and signaling operations. The construction typically includes reinforced endposts, wear-resistant surface treatments, and precision-engineered gaps that accommodate thermal expansion while preserving electrical separation. Modern insulation joints integrate monitoring capabilities for predictive maintenance, enabling railway operators to track joint performance and schedule maintenance proactively. The technology has evolved to include smart sensors that can detect potential failures before they occur, ensuring maximum track availability and safety.