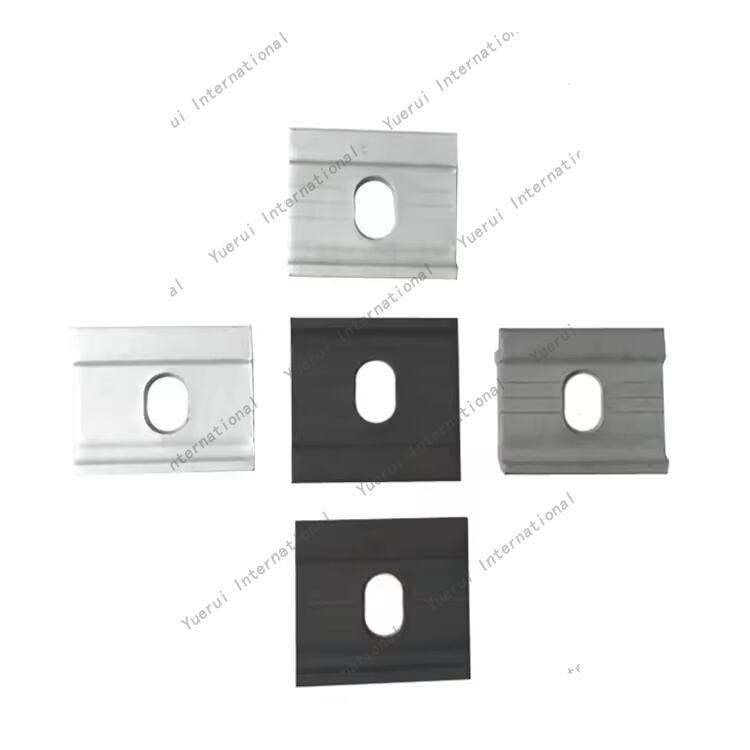

railway gauge plate

The railway gauge plate is a critical component in rail infrastructure maintenance and safety monitoring systems. This precision-engineered device serves as a fundamental tool for measuring and maintaining the standard distance between railway tracks. Manufactured from high-grade materials, typically hardened steel or durable alloys, these plates are designed to withstand extreme weather conditions and continuous use in demanding railway environments. The gauge plate features carefully calibrated markings and measurement points that allow maintenance crews to verify track spacing with exceptional accuracy. Modern railway gauge plates often incorporate advanced measurement technologies, including digital displays and electronic sensors, enabling real-time data collection and analysis. These devices are essential for ensuring compliance with international railway safety standards and maintaining optimal track geometry. The plate's design typically includes ergonomic handles and lightweight construction for easy handling during inspection routines, while maintaining the structural integrity necessary for precise measurements. Railway gauge plates are used across various railway systems, from high-speed rail networks to urban transit systems, playing a vital role in preventing derailments and ensuring smooth train operations.