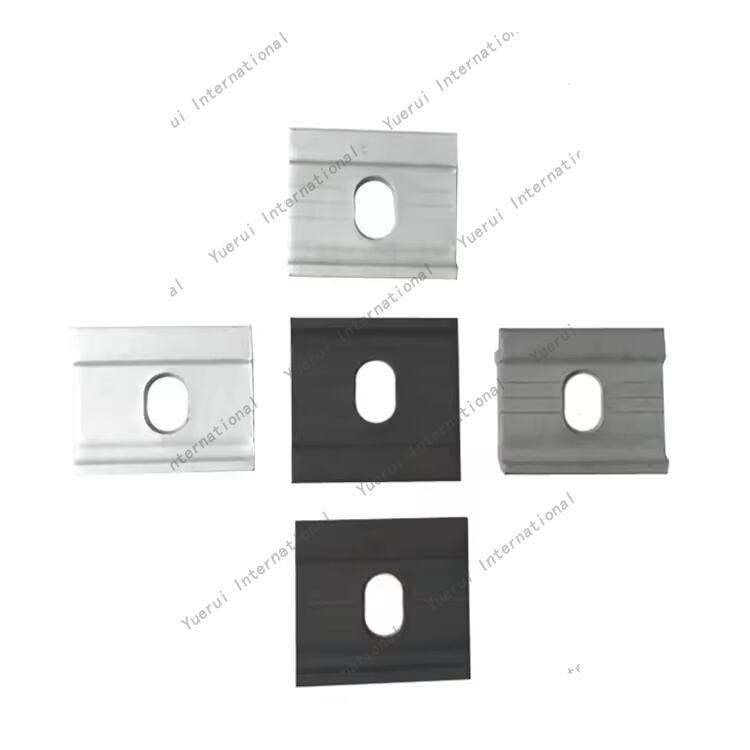

g5 g7 gauge plate

The G5 G7 gauge plate represents a pinnacle of precision engineering in modern manufacturing processes. This specialized measurement tool is designed to maintain exceptional accuracy in dimensional control and quality assurance applications. Manufactured to strict tolerances, these gauge plates serve as reference standards for calibration and measurement in industrial settings. The G5 classification indicates a high-precision grade suitable for general inspection work, while G7 offers an even finer degree of accuracy for more demanding applications. These gauge plates are typically crafted from high-grade tool steel or chromium-alloy materials, ensuring long-term dimensional stability and wear resistance. The surface finish is meticulously processed to achieve flatness and parallelism within microns, making them ideal for various measurement tasks. They are extensively used in machine shops, quality control departments, and calibration laboratories for verifying measuring instruments, setting up precision equipment, and maintaining measurement standards. The versatility of G5 G7 gauge plates extends to their application in both contact and non-contact measurement systems, providing reliable reference surfaces for dimensional metrology.