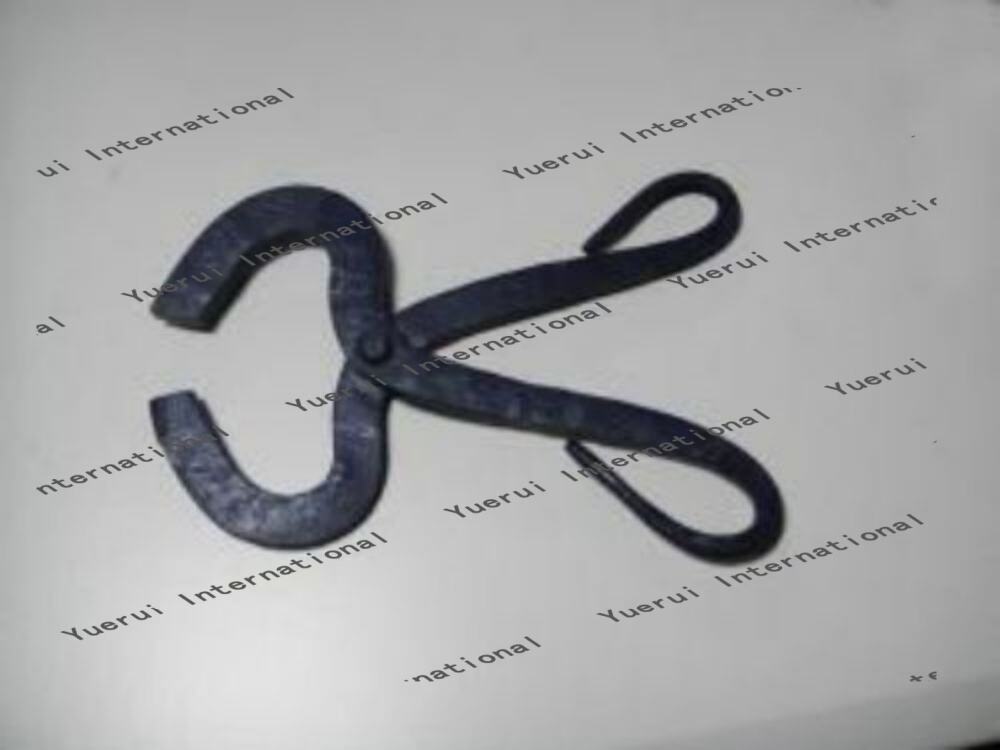

railroad bar tool

The railroad bar tool, also known as a track maintenance bar, is an essential implement designed specifically for railroad track maintenance and construction work. This versatile tool features a heavy-duty steel construction with a distinctive design that includes a flat chisel end and a curved neck leading to a pointed tip. The tool typically measures between 5 to 6 feet in length, providing optimal leverage for various track-related tasks. Its primary functions include aligning railroad tracks, adjusting rail positions, removing spikes, and manipulating tie plates. The bar's unique construction allows workers to efficiently pry, lift, and position heavy rail components with minimal physical strain. The tool's durability is enhanced through heat-treated steel manufacturing, ensuring resistance to wear and tear under demanding conditions. Modern versions often incorporate ergonomic features such as non-slip grips and balanced weight distribution for improved handling. The railroad bar tool's versatility extends to various applications, including emergency track repairs, routine maintenance procedures, and new track installation projects. Its design enables precise movements when adjusting track alignment and maintains critical safety standards in rail infrastructure maintenance.