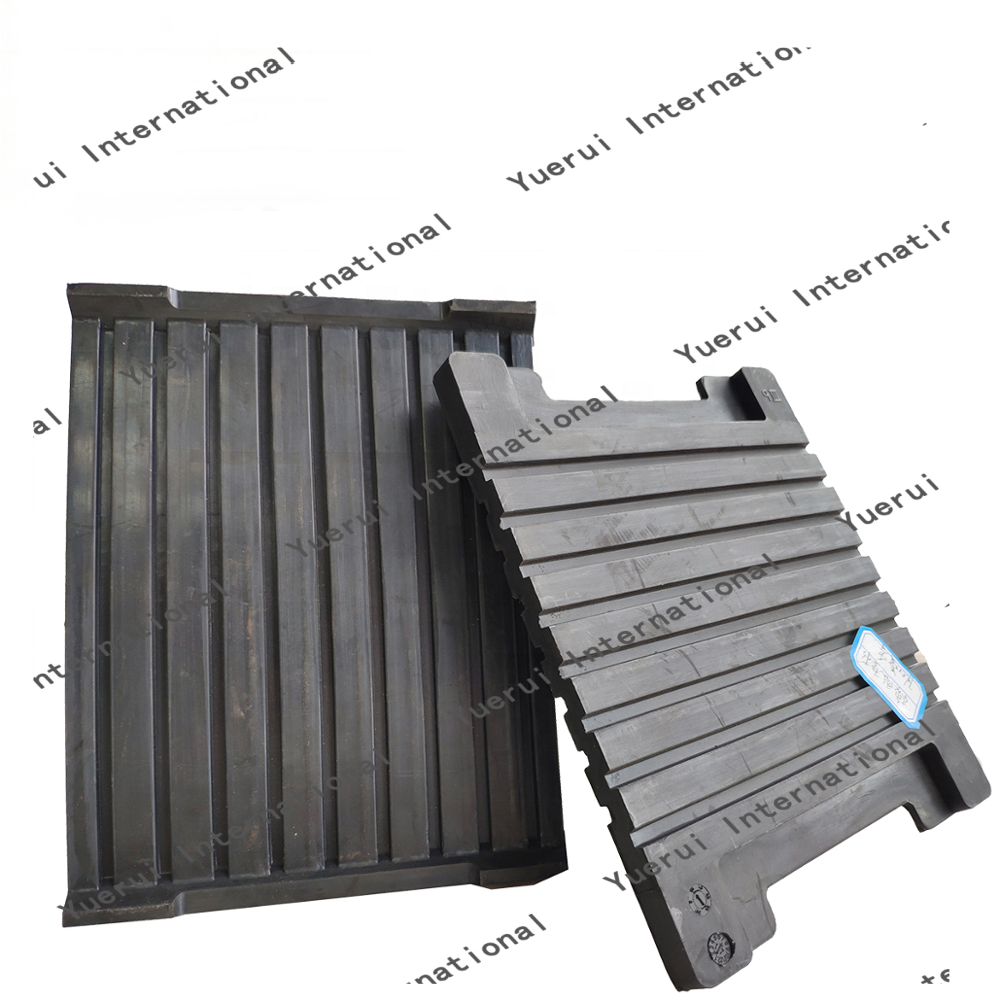

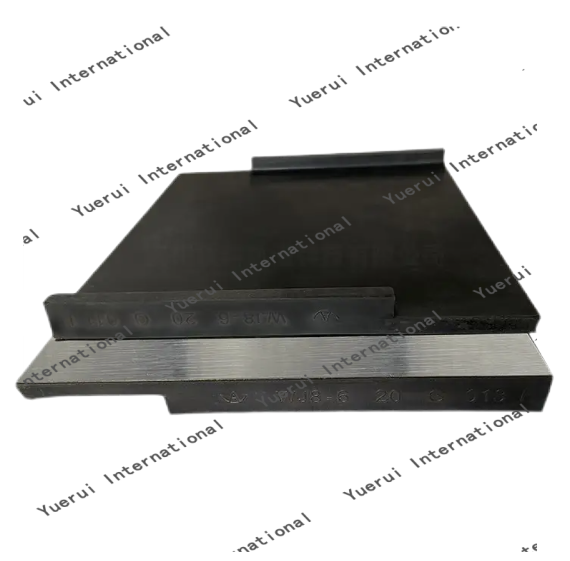

rubber heating pad

A rubber heating pad represents a versatile thermal solution that combines durability with efficient heat distribution. This innovative heating device consists of a robust rubber exterior encasing carefully engineered heating elements, designed to provide consistent and reliable warmth across its surface. The pad's construction features multiple layers of industrial-grade rubber compounds that ensure both safety and longevity. Operating through electrical resistance heating, these pads can achieve and maintain precise temperatures, typically ranging from ambient to 200°F (93°C), making them suitable for various applications. The rubber composition offers excellent chemical resistance and waterproof properties, while its flexible nature allows it to conform to different surface shapes. Advanced models incorporate temperature sensors and controllers for precise heat regulation, ensuring optimal performance and energy efficiency. These heating pads find extensive use in industrial processes, laboratory applications, and commercial settings where consistent heat application is crucial. The design typically includes reinforced power connections and integrated thermal protection systems to prevent overheating, making them both safe and reliable for continuous operation.