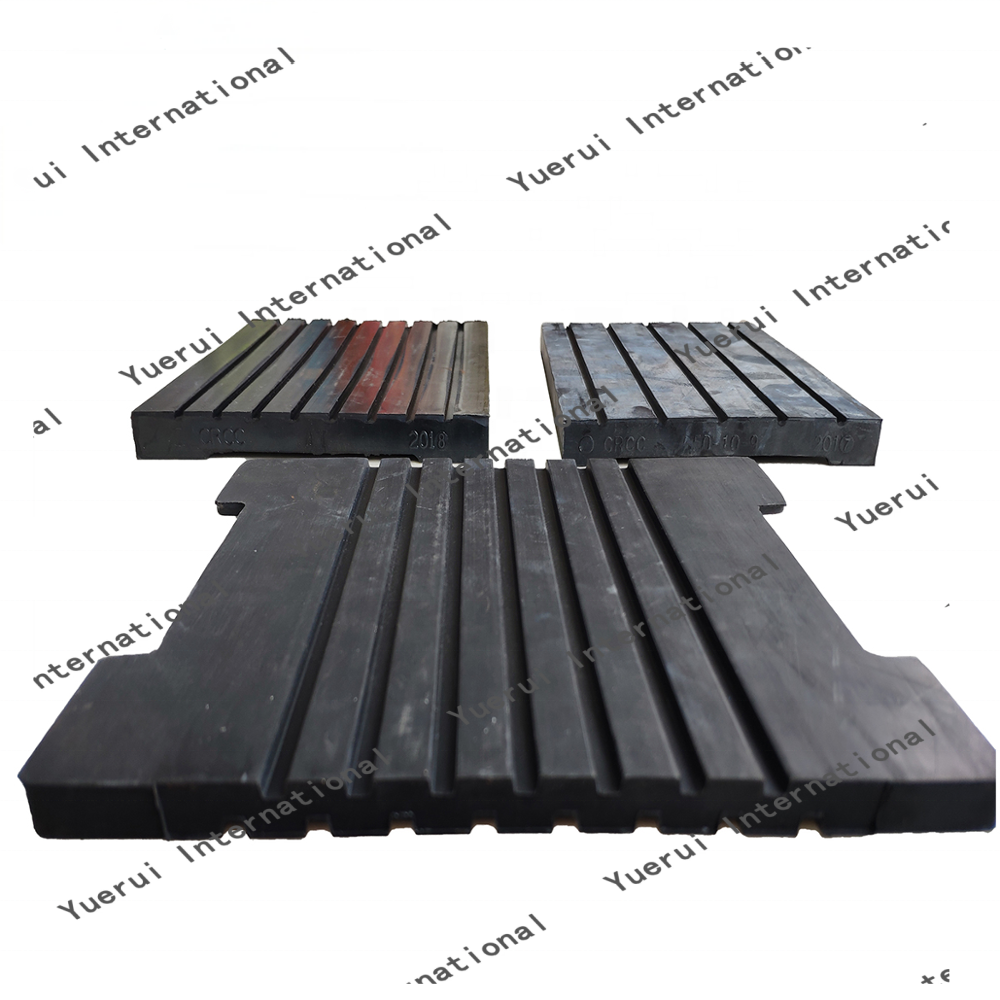

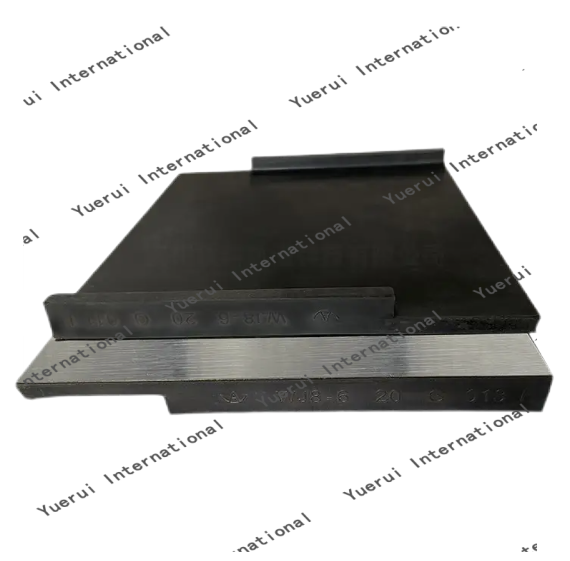

rubber isolation pads

Rubber isolation pads represent a crucial component in modern construction and industrial applications, serving as essential vibration control solutions. These engineered products consist of high-quality elastomeric materials specifically designed to absorb and dampen vibrations, shock, and noise transmission between mechanical equipment and supporting structures. The pads feature a unique molecular structure that allows them to compress under load while maintaining their resilience and recovery properties. Available in various thicknesses, durometers, and sizes, these isolation pads can be customized to meet specific load requirements and performance criteria. Their construction typically incorporates reinforced rubber compounds that resist degradation from environmental factors such as UV exposure, oil contamination, and temperature fluctuations. The pads effectively reduce structure-borne noise by creating a flexible barrier between vibrating equipment and the supporting surface, helping to prevent the transmission of unwanted mechanical energy. In industrial settings, these pads are commonly installed beneath heavy machinery, HVAC equipment, generators, and pumps to protect both the equipment and surrounding structures from harmful vibrations. The technology behind rubber isolation pads continues to evolve, with manufacturers developing advanced compounds and designs to meet increasingly demanding applications in various industries.