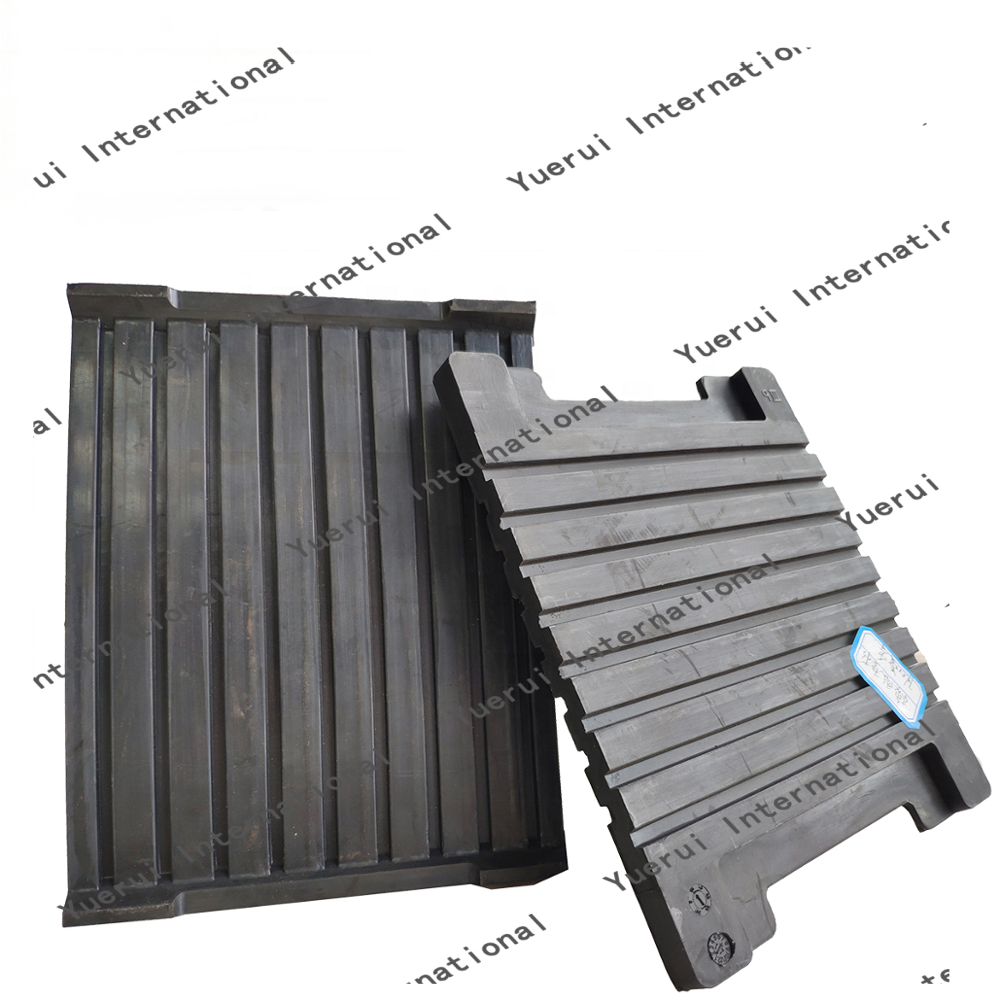

rubber cushion pad

A rubber cushion pad is an essential industrial component designed to provide shock absorption, vibration dampening, and load distribution in various applications. These versatile pads are manufactured using high-quality elastomeric materials, engineered to withstand extensive compression while maintaining their structural integrity. The pad's unique composition features a specialized rubber compound that offers optimal resilience and durability, making it ideal for both static and dynamic load conditions. The design typically incorporates strategically placed grooves or patterns that enhance its compression characteristics and ensure even weight distribution. These pads come in various thicknesses, densities, and sizes to accommodate different load requirements and installation specifications. The rubber cushion pad's primary function is to minimize the transmission of vibrations and impacts between surfaces, effectively protecting equipment and structures from potential damage. They are particularly valuable in construction, manufacturing, and industrial settings where equipment stability and noise reduction are crucial. The pad's ability to absorb shock and reduce noise makes it an invaluable component in machinery foundations, bridge bearings, railway track systems, and various other applications requiring reliable vibration isolation.