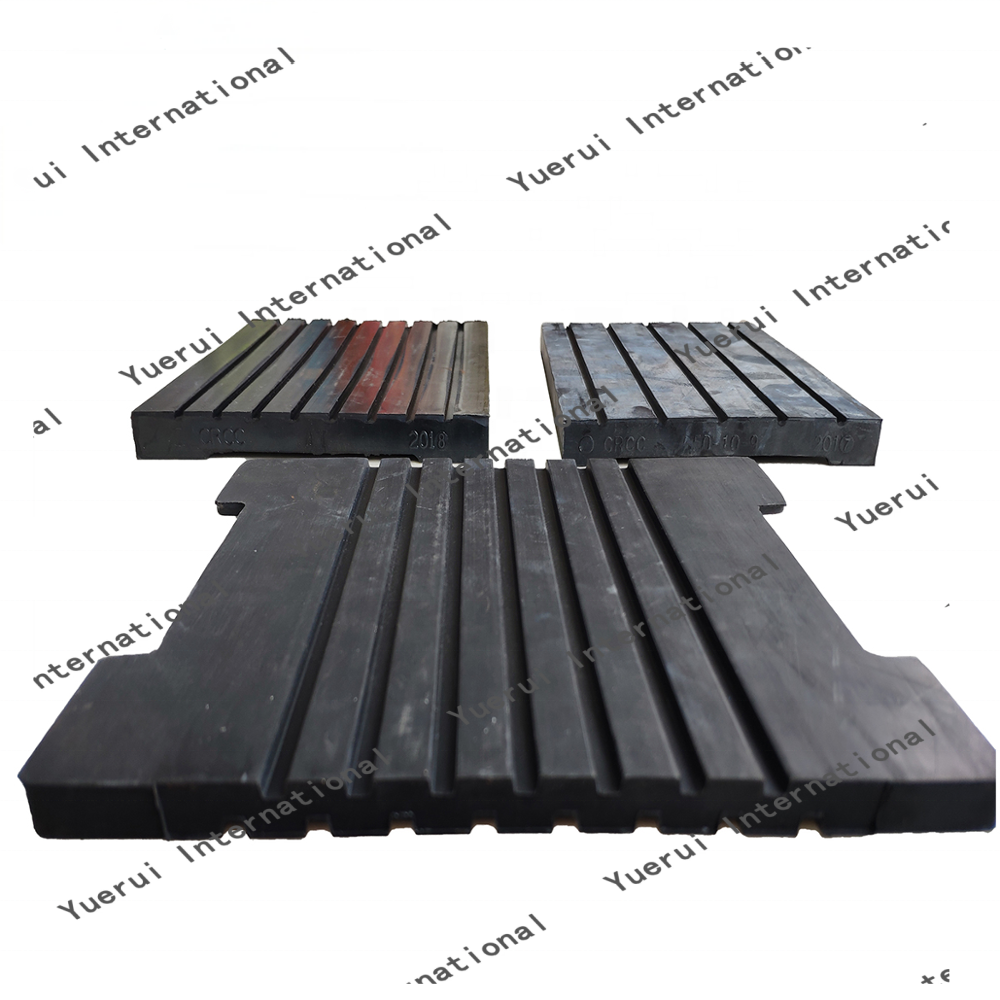

trimming plate

A trimming plate is an essential industrial component designed to provide precise and controlled material removal in various manufacturing processes. This sophisticated piece of equipment combines durability with precision engineering to deliver consistent results in metal fabrication, woodworking, and other industrial applications. The plate features carefully engineered cutting surfaces, typically made from high-grade steel or carbide materials, that enable smooth and accurate trimming operations. Its design incorporates advanced wear-resistant properties, ensuring longevity even under demanding conditions. The trimming plate's surface is specifically calibrated to maintain dimensional accuracy while processing different materials, making it an invaluable tool in production lines. Modern trimming plates often include innovative features such as adjustable angles, replaceable cutting edges, and specialized coatings that enhance performance and extend service life. These plates are manufactured to strict tolerances, ensuring consistent quality across all trimming operations. The versatility of trimming plates makes them suitable for various industries, from automotive manufacturing to packaging production, where precise material removal is critical for final product quality.