rubber pad price

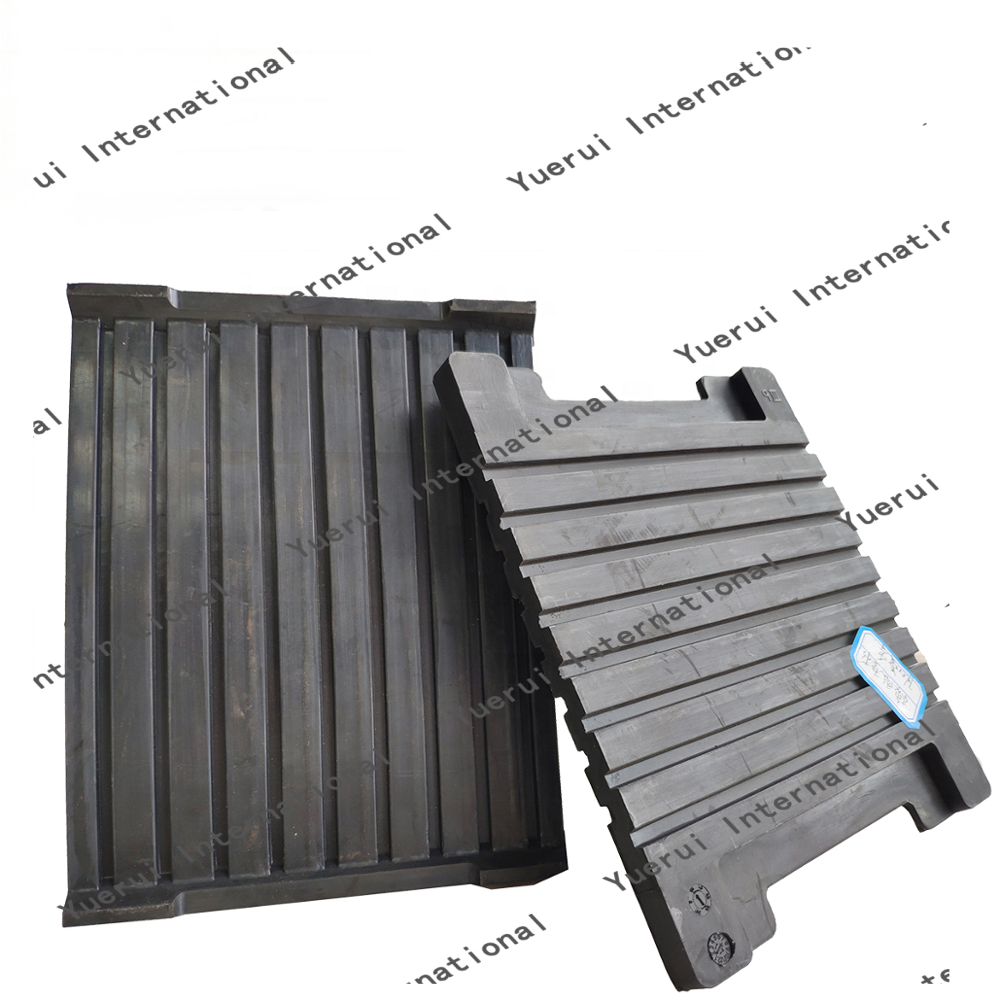

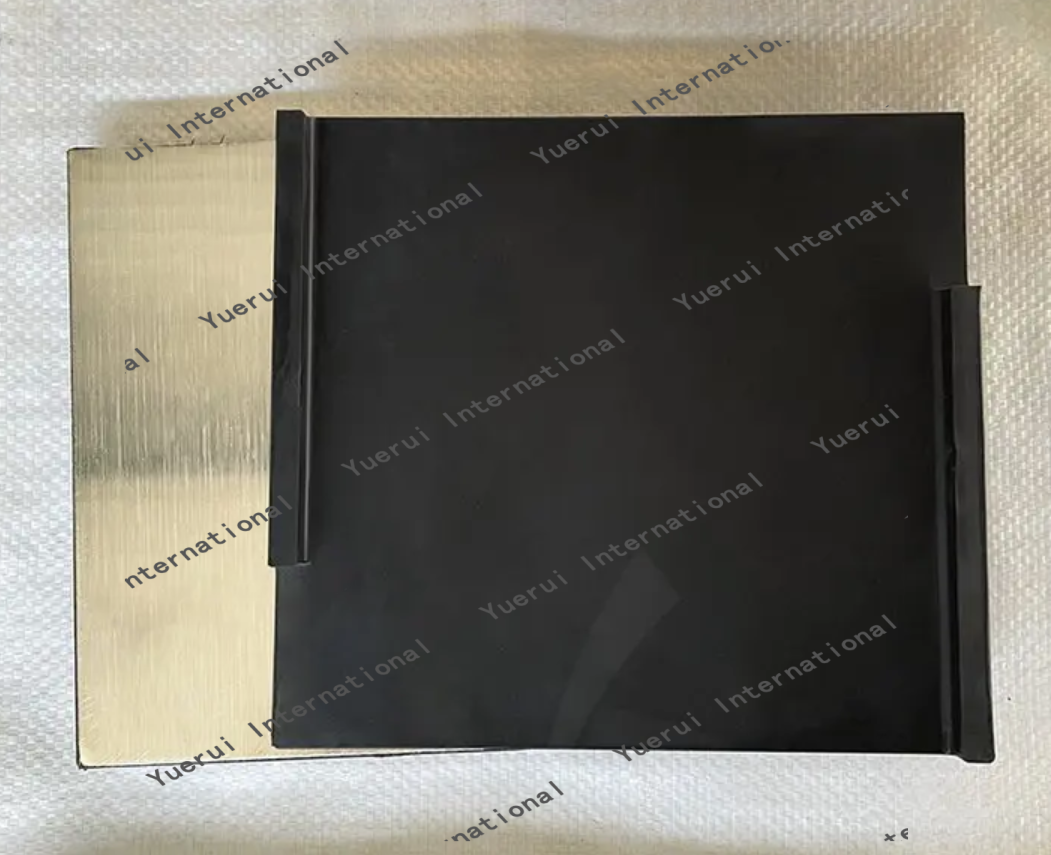

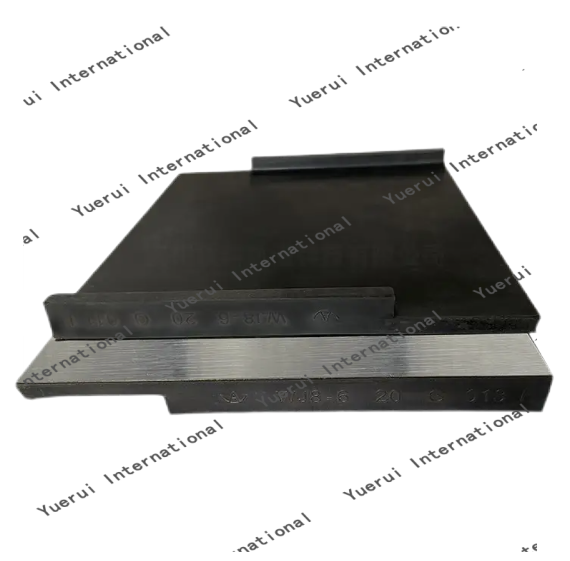

Rubber pad pricing encompasses a comprehensive evaluation of high-quality materials, manufacturing processes, and market demands. These essential components are designed to provide cushioning, vibration dampening, and protection across various industrial and commercial applications. The price point reflects factors such as material grade, durometer rating, size specifications, and quantity requirements. Modern rubber pads incorporate advanced polymer technologies, ensuring optimal performance in demanding environments while maintaining cost-effectiveness. Manufacturers consider factors like wear resistance, temperature tolerance, and chemical compatibility when determining pricing structures. The market offers various options, from standard natural rubber compounds to specialized synthetic blends, each with distinct price points reflecting their performance capabilities. Pricing typically includes considerations for customization options, such as specific shapes, sizes, and surface patterns that enhance functionality. The cost structure also accounts for quality control measures, compliance with industry standards, and durability requirements that ensure long-term value for customers.