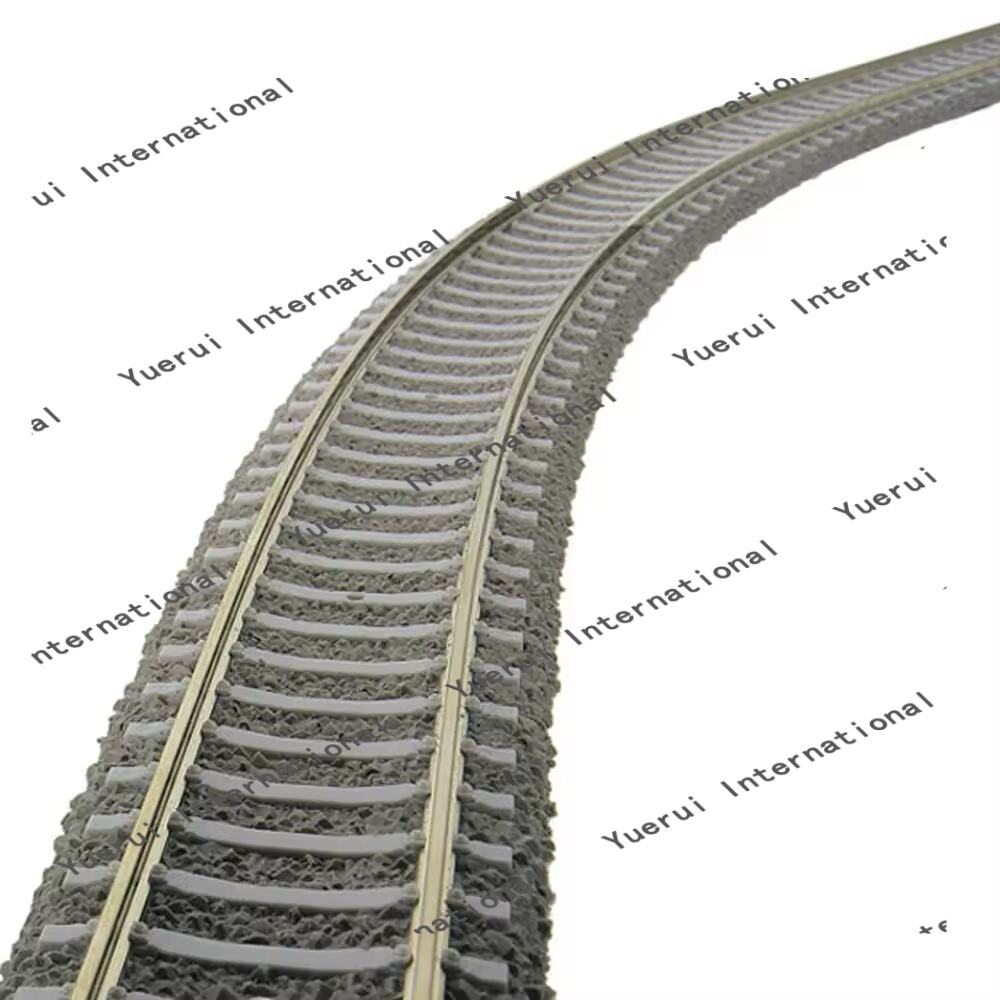

synthetic railroad ties

Synthetic railroad ties represent a revolutionary advancement in railway infrastructure, offering a modern alternative to traditional wooden ties. These engineered components are manufactured using recycled plastic materials and innovative composite technologies, delivering superior durability and performance in rail applications. The ties are designed to withstand extreme weather conditions, heavy loads, and continuous stress while maintaining their structural integrity. They feature advanced internal reinforcement systems that provide exceptional strength and stability, crucial for maintaining track geometry and ensuring safe rail operations. These synthetic ties are engineered with precise dimensions and specifications to meet industry standards, incorporating UV protection and chemical resistance properties. Their design includes specialized fastening systems that ensure secure rail attachment and proper gauge maintenance. The material composition allows for excellent electrical insulation, reducing signal interference and maintenance requirements. These ties are particularly valuable in areas with high moisture exposure or extreme temperature variations, where traditional wooden ties might deteriorate rapidly. The manufacturing process ensures consistency in quality and performance, with each tie meeting strict quality control standards. Their implementation has proven successful in various railway applications, from heavy freight lines to light rail transit systems, demonstrating their versatility and reliability.