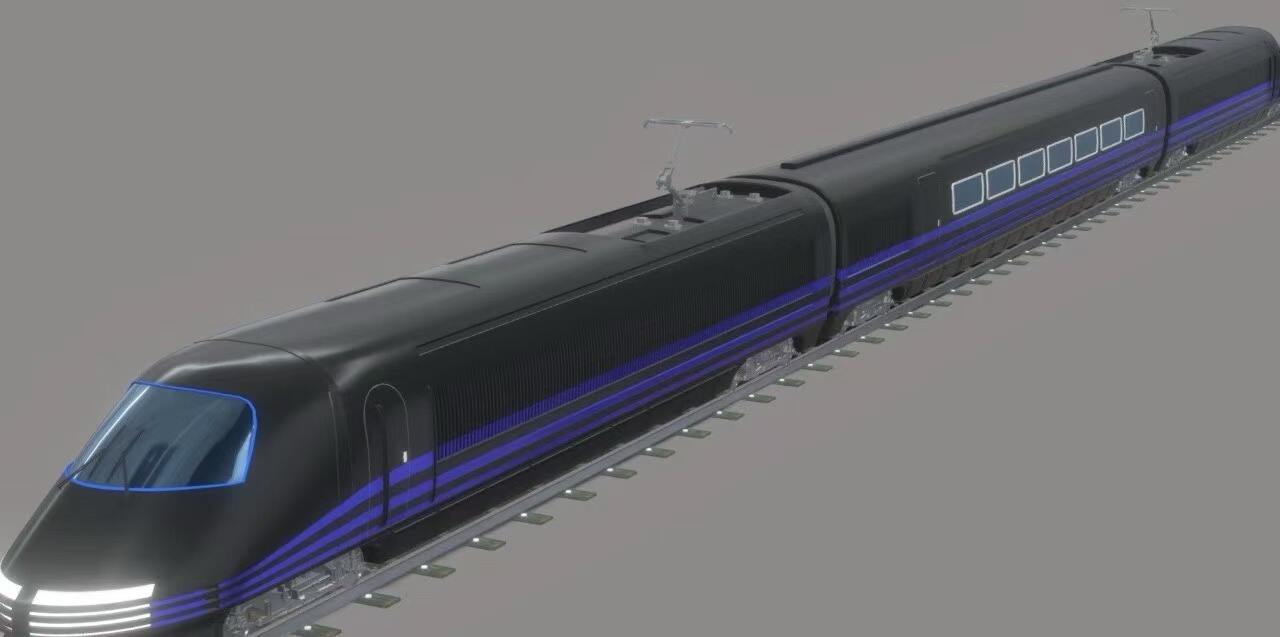

The structure of 3D-printed continuous fiber-reinforced thermoplastic composites (CFRTPC) features multi-scale characteristics of microfiber paths and macrostructures. A European research consortium is developing an innovative thermoplastic technology that combines large-format 3D printing with 3D tape laying processes, enabling the production of large, complex and flexible rail vehicle components (such as front covers and roof structures) without molds.

This technology has significant optimization potential in terms of cost, time and materials for small and medium-sized series components, and can reduce carbon footprint. Compared with traditional thermosetting fiber composite processes, it eliminates molds, is highly automated and uses recyclable materials, which can reduce costs and improve resource efficiency.