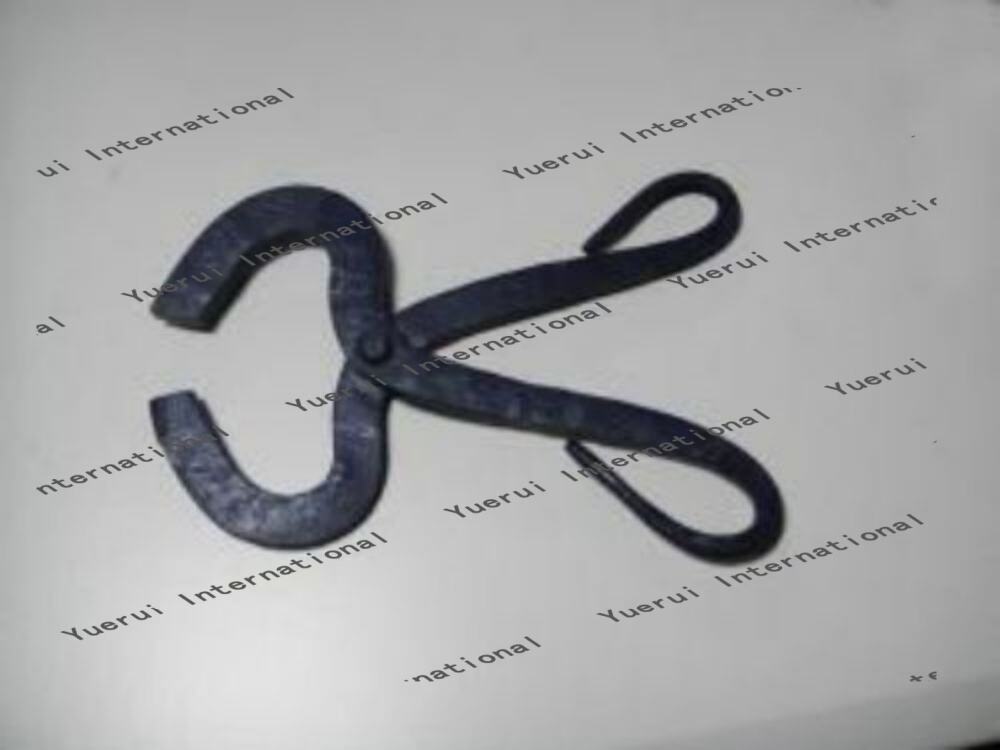

rail tools

Rail tools represent a comprehensive suite of specialized equipment designed for the installation, maintenance, and inspection of railway infrastructure. These advanced tools incorporate cutting-edge technology to ensure precise measurements, efficient operations, and reliable performance in railway maintenance tasks. The collection includes track geometry measurement devices, rail profile analyzers, ultrasonic testing equipment, and track alignment tools. These instruments utilize sophisticated sensors and digital technology to provide accurate readings and real-time data analysis. The tools are engineered to meet strict industry standards and safety regulations, featuring ergonomic designs for comfortable handling and robust construction to withstand demanding railway environments. They play a crucial role in preventive maintenance, helping to identify potential issues before they become critical problems. The suite includes both manual and automated tools, offering flexibility for various applications and working conditions. Modern rail tools often feature integrated data management systems, allowing for seamless documentation and analysis of inspection results. This technological integration enables better decision-making and more efficient maintenance scheduling, ultimately contributing to the overall safety and reliability of railway operations.