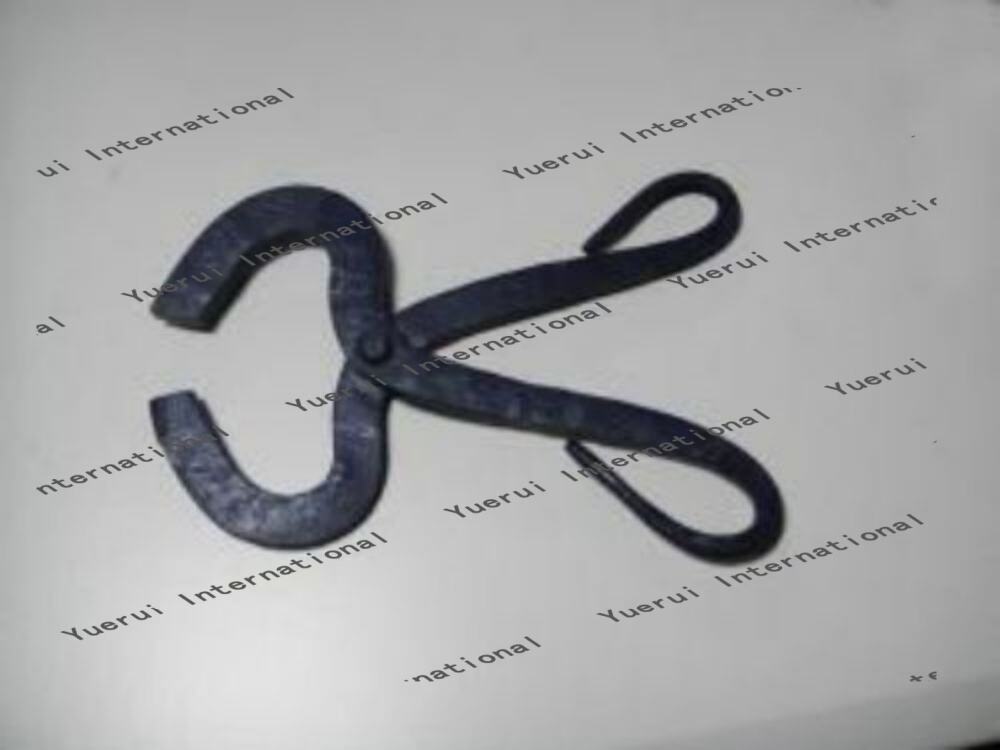

guide rail clamp

A guide rail clamp is an essential mechanical component designed to secure and stabilize linear motion systems in various industrial applications. This precision-engineered device provides reliable clamping force to maintain proper alignment and position of guide rails, ensuring smooth and accurate linear movement. The clamp consists of a robust body, typically manufactured from high-grade steel or aluminum, featuring precision-machined surfaces and strategically positioned mounting holes. Its innovative design incorporates spring-loaded mechanisms or hydraulic systems that deliver consistent clamping pressure, preventing unwanted movement or vibration during operation. Guide rail clamps are available in various sizes and configurations to accommodate different rail profiles and load requirements. They often feature adjustable clamping forces, allowing users to fine-tune the holding power based on specific application needs. Advanced models may include integrated sensors for position monitoring and safety interlocks. These clamps are crucial in maintaining system stability in automated manufacturing processes, CNC machinery, and high-precision assembly lines.